Automatic packaging production line for gas water heaters

A gas water heater and automatic packaging technology, which is applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems that the quality and efficiency of the process cannot be guaranteed, cannot meet the needs of large-scale industrial production, and manual errors are easy to occur. Effective utilization rate, major social and economic benefits, and the effect of reducing production safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

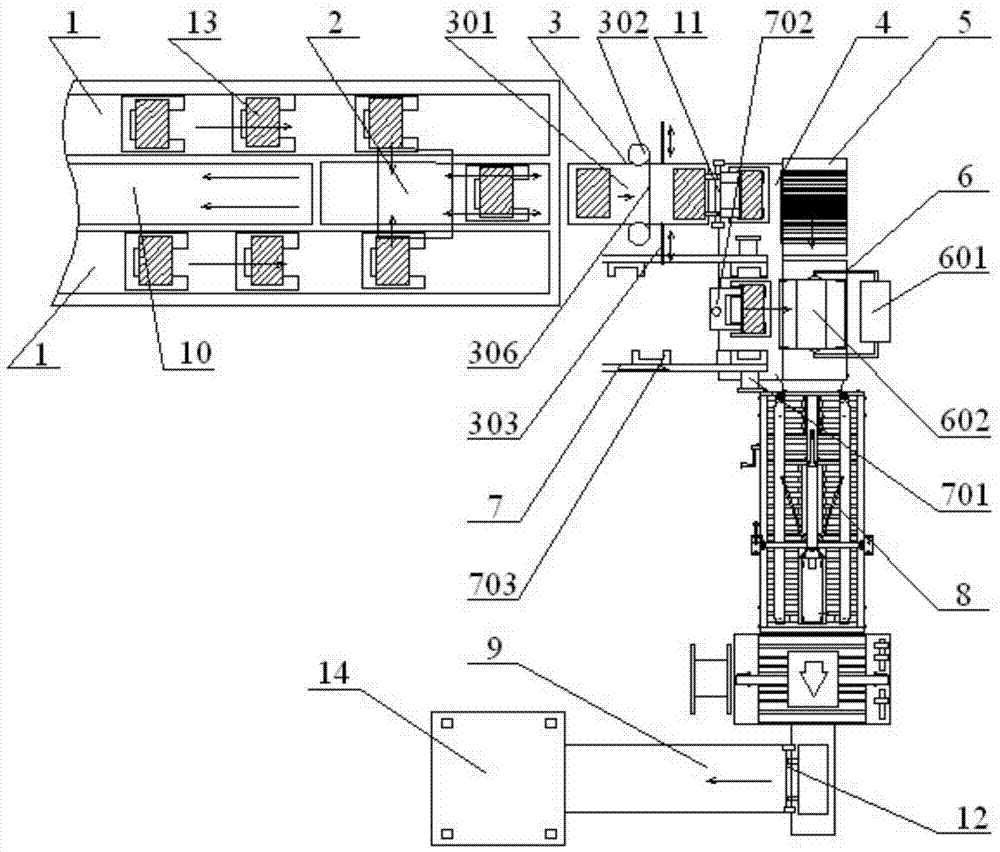

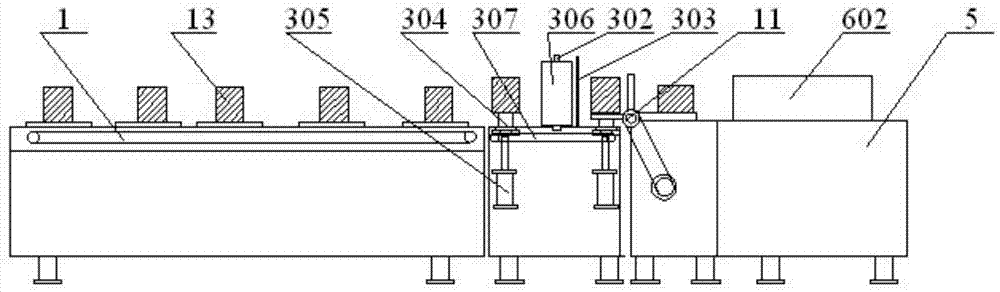

[0028] Such as figure 1 and figure 2 As shown, a gas water heater automatic packaging production line of the present invention includes a conveying production line 1, a labeling machine 2, a film sealing machine 3, a product conveying station 4, a carton conveying station 5, an unpacking machine 6, a plastic concave pad conveying line 7, a sealing Box line 8, finished product line 9, and robot stacker 14; one side of the conveying production line 1 is provided with a labeling machine 2, and the labeling machine 2 is connected to the film sealing machine 3 through a conveying mechanism, and the film sealing machine 3 is connected to the product The conveying platform 4 is set in a 90° turn, and the carton conveying platform 5 is adjacent to and parallel to the product conveying platform 4. The carton conveying platform 5, the unpacking machine 6, and the sealing line 8 are connected vertically in sequence according to the conveying direction. One end of the finished product l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com