ICP (inductively coupled plasma) processing machine tool cavity air pressure control method based on PLC (programmable logic controller)

A plasma and processing machine tool technology, which is applied in the field of plasma processing machine tool cavity air pressure control, can solve problems such as endangering the health of operators and polluting the environment, and achieve the effects of being easy to master, preventing environmental pollution, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

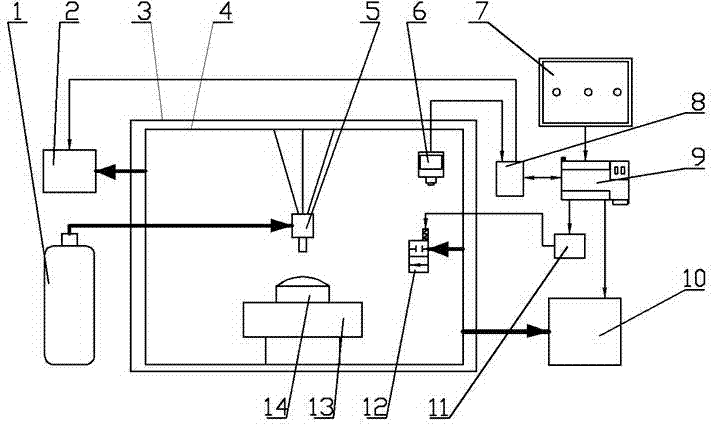

[0019] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

[0020] Such as figure 1 As shown, the PLC-based ICP plasma processing machine tool cavity air pressure control method provided by the present invention, the specific implementation steps are as follows:

[0021] Step 1: Before processing, place the workpiece 14 on the displacement platform 13, close the airtight door of the machine tool, ensure that the wiring of each place is normal, and then power on the plasma processing machine tool and each controller, and press the button on the operation panel to make the machine tool enter the debugging state ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com