Hemodialysis medicinal component sodium diacetate preparation method

A technology of sodium diacetate and medicinal ingredients, which is applied in the field of preparation of sodium diacetate, can solve the problems of not meeting the requirements of medicines, high chloride content, high heavy metal content, etc., to reduce medical costs, low chloride and heavy metal content, and production high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

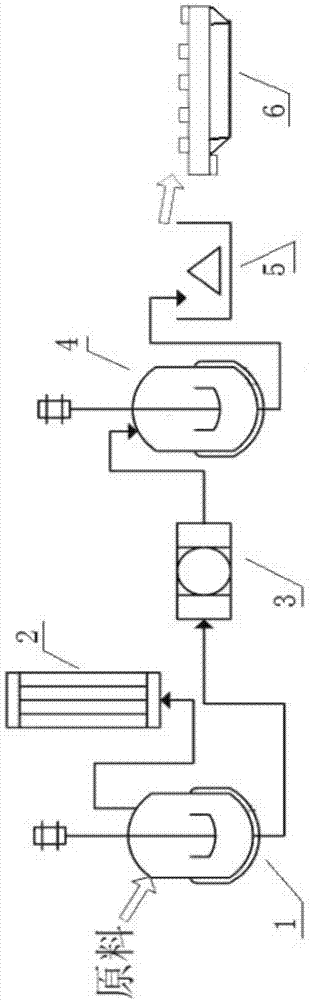

Image

Examples

Embodiment 1

[0025] Add 7Kg of medicinal sodium acetate into the reaction kettle, heat and stir, and at the same time dropwise add 5Kg of food-grade glacial acetic acid to the reaction kettle for reaction, heat after the reaction, keep the temperature at 110-120°C for 1 hour, filter while hot, and The material was transported to a cooling crystallizer, cooled to room temperature to obtain crystals, and the crystals were quickly dried to obtain 4.1Kg of sodium diacetate that meets the requirements of medicine, with a yield of 56%.

[0026] The products have been tested to meet the enterprise standards.

Embodiment 2

[0028] Add 7Kg of medicinal sodium acetate into the reaction kettle, heat and stir, and at the same time add 4.1Kg of food-grade glacial acetic acid dropwise to the reaction kettle for reaction. After the reaction is completed, heat, keep the temperature at 110-120°C and reflux for 1.5h, and filter while it is hot , transport the material to a cooling crystallizer, cool to room temperature, obtain crystals, and dry the crystals quickly to obtain 4.2Kg of sodium diacetate that meets the requirements of medicine, with a yield of 57%.

[0029] The products have been tested to meet the enterprise standards.

Embodiment 3

[0031] Add 7Kg of medicinal sodium acetate into the reaction kettle, heat and stir, and at the same time add 7.5Kg of food-grade glacial acetic acid dropwise to the reaction kettle for reaction. After the reaction is completed, heat, keep the temperature at 110-120°C and reflux for 2 hours, and filter while it is hot. The material was transported to a cooling crystallizer, cooled to room temperature, crystallization was obtained, and the crystallization was quickly dried to obtain 3.95Kg of sodium diacetate suitable for medicinal use, with a yield of 54%.

[0032] The products have been tested to meet the enterprise standards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com