Method for improving fungus-proof performance of rubber material

A rubber material and anti-mold technology, which is applied in the field of aviation material manufacturing, can solve problems that affect the flight safety of aircraft, accelerate aging, and reduce material performance, and achieve the effect of improving anti-mold performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

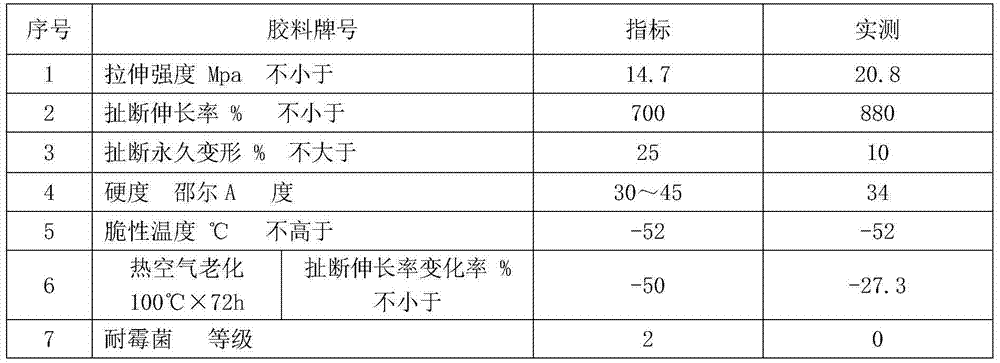

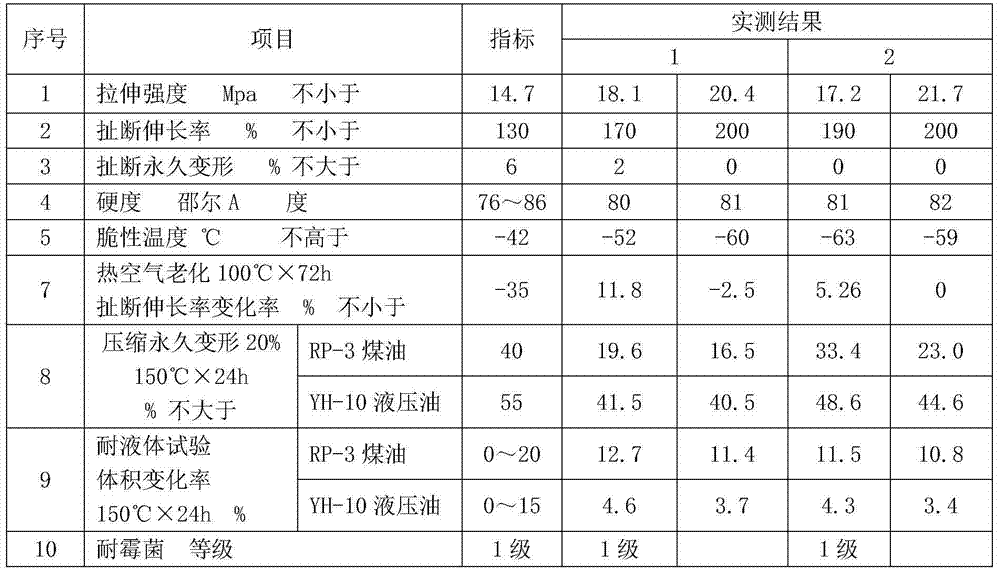

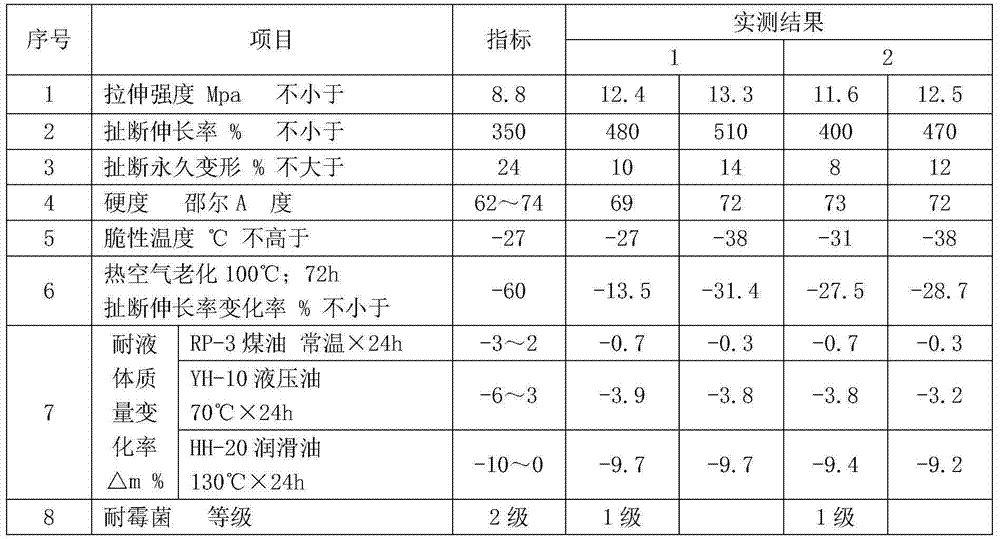

Examples

Embodiment Construction

[0009] The specific implementation manners of the present invention will be further described below.

[0010] Represented by rubber compound, the technical solution to improve the anti-mold performance of rubber compound is: increasing the polarity of rubber can inhibit the growth of mold and improve the anti-mold performance of rubber. Therefore, according to the requirements of anti-mold, it is necessary to choose an appropriate type of anti-mold The mold agent is added to the rubber compound. The types of antifungal agents suitable for rubber products are: 5,6-dichlorobenzoxazolone (trade name: antifungal agent O), benzoimidazole methyl carbamate (trade name: antifungal agent BCM), 75 No. antifungal agent, YL-4 composite antifungal agent. The specific implementation plan is as follows:

[0011] 1) Raw rubber masterbatch: add fillers and additives (plasticizers, anti-aging agents) to the raw rubber, and then masterbatch (35-45) min;

[0012] 2) Filtration: Carry out two-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com