RH cold steel removing method

A technology of cold steel and top gun, applied in the field of RH removal of cold steel, can solve the problems of potential safety hazards, inability to be completely enclosed, and short-term confined space, etc., to improve safety, avoid loud explosions and explosions, and shorten the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

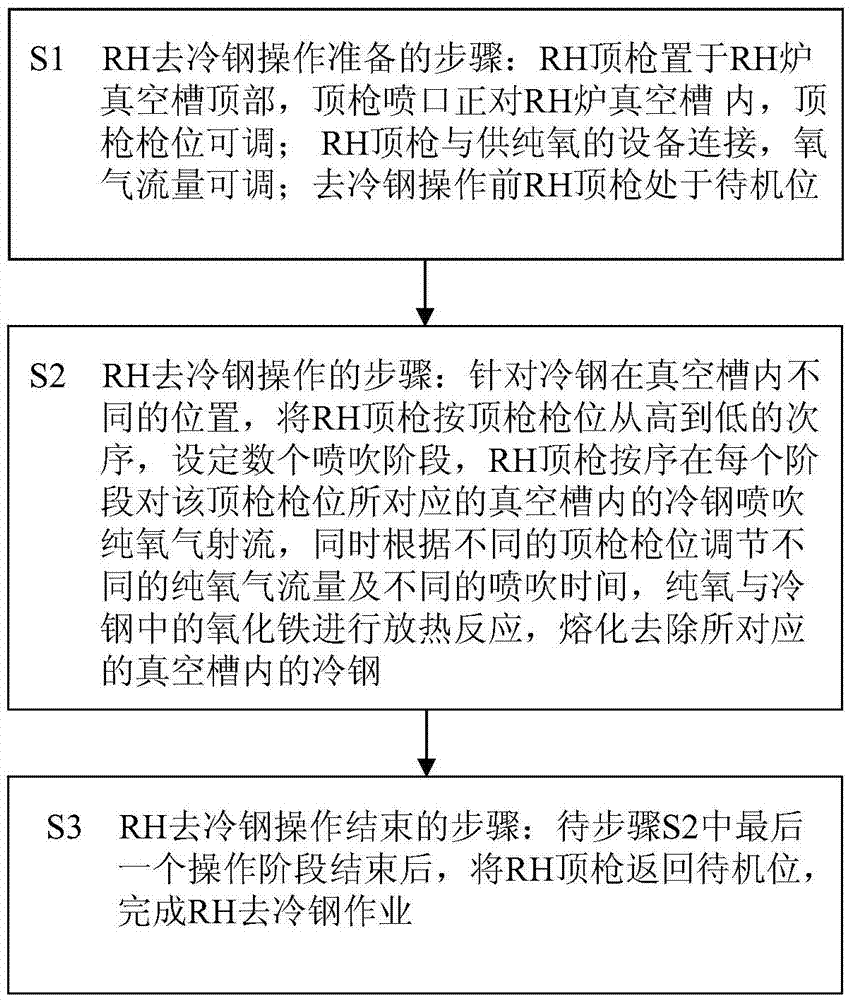

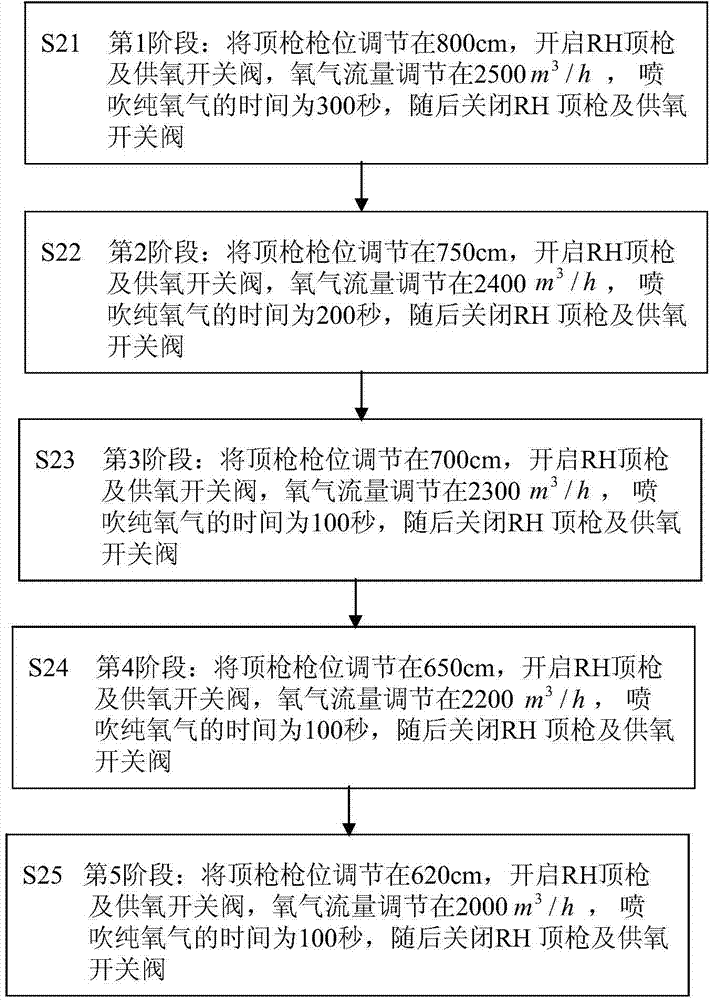

[0031] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings of the embodiments.

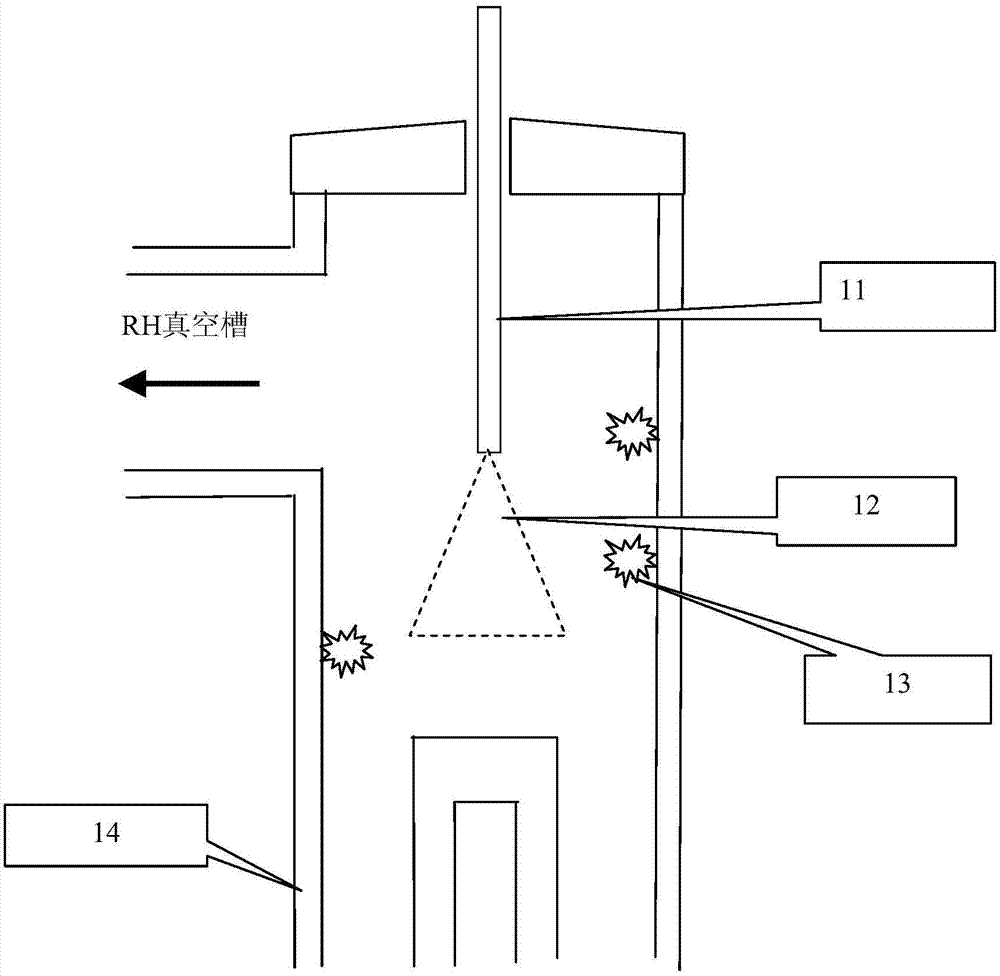

[0032] In the present invention, the RH top lance is used to spray pure oxygen to directly react with cold steel, which greatly improves the efficiency of removing cold steel. see figure 1 , the RH top gun 11 adopts pure oxygen to remove the cold steel, that is, the RH top gun 11 sprays the pure oxygen jet 12 to the cold steel 13 on the wall of the RH dipping tube 14 in the RH vacuum tank, because the pure oxygen directly interacts with the iron in the cold steel reaction, namely 2[Fe]+O 2 =2FeO and 4FeO+O2=2Fe 2 o 3 , the reaction is an exothermic reaction, and the calorific value is extremely high, and the reaction speed is fast. Therefore, direct use of pure oxygen to melt and remove cold steel can obtain a high efficiency of removing cold steel. In addition, the oxygen content in pure oxygen exceeds 99%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com