Al-mg-si series aluminum alloy material with long-term natural aging stability, aluminum alloy plate and manufacturing method thereof

An aluminum alloy material and natural aging technology, which is applied in the field of aluminum alloy materials, can solve the problems of increasing the material cycle, achieve the effects of uniform size, excellent mechanical properties, and improve processing plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

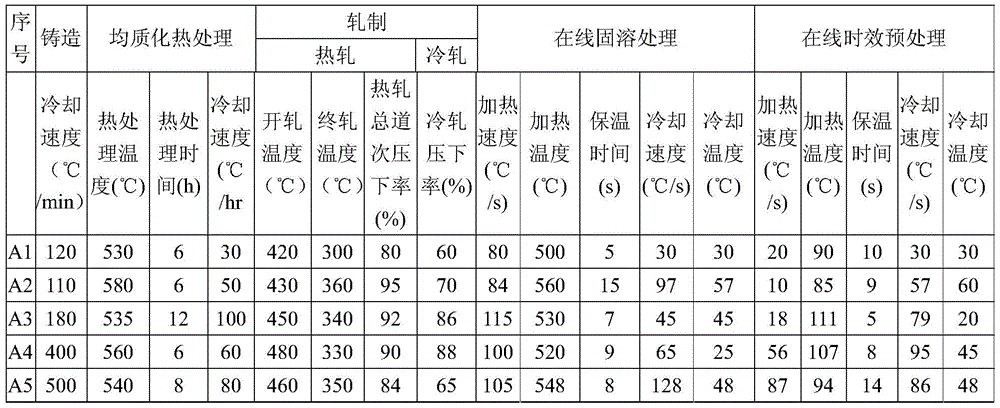

Examples

Embodiment Construction

[0069] The Al-Mg-Si series aluminum alloy material, aluminum alloy plate and its manufacturing method with long-term natural aging stability described in the present invention will be further explained and illustrated in conjunction with the accompanying drawings and specific examples. However, The explanations and illustrations do not constitute undue limitations on the technical solution of the present invention.

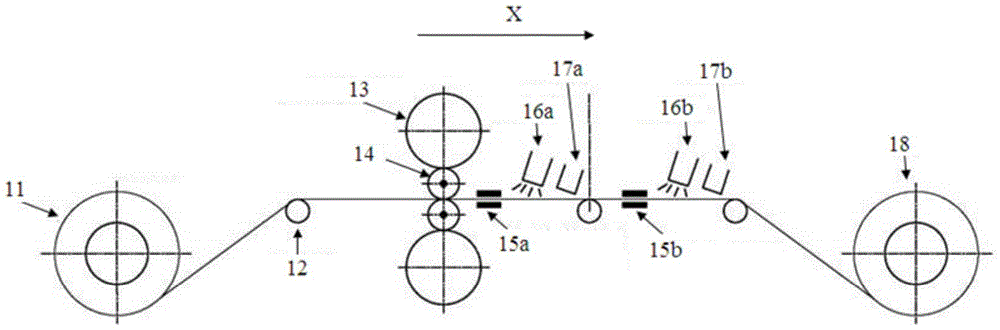

[0070] figure 1 The structure of a rolling mill facility for realizing the rolling, in-line solution treatment, and in-line aging pretreatment steps in the following manufacturing method is shown.

[0071] Such as figure 1 As shown, the rolling mill equipment is arranged in sequence along the traveling direction X of the slab: a left coiler 11, a right diverting roll 12, a rolling mill backup roll 13, a rolling mill working roll 14, a first online induction heating device 15a, and a first water cooling device 16a, the first air cooling device 17a, the second onl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com