Iron finishing machine iron finishing roller structure

A technology for ironing rollers and ironing machines, which is used in textiles and papermaking, fabric surface trimming, etc., can solve the problems of high energy consumption, increased maintenance and use costs, and difficult to control the surface temperature of ironing rollers, and achieves uniform temperature and saves. Energy consumption, the effect of guaranteeing the quality of hot polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

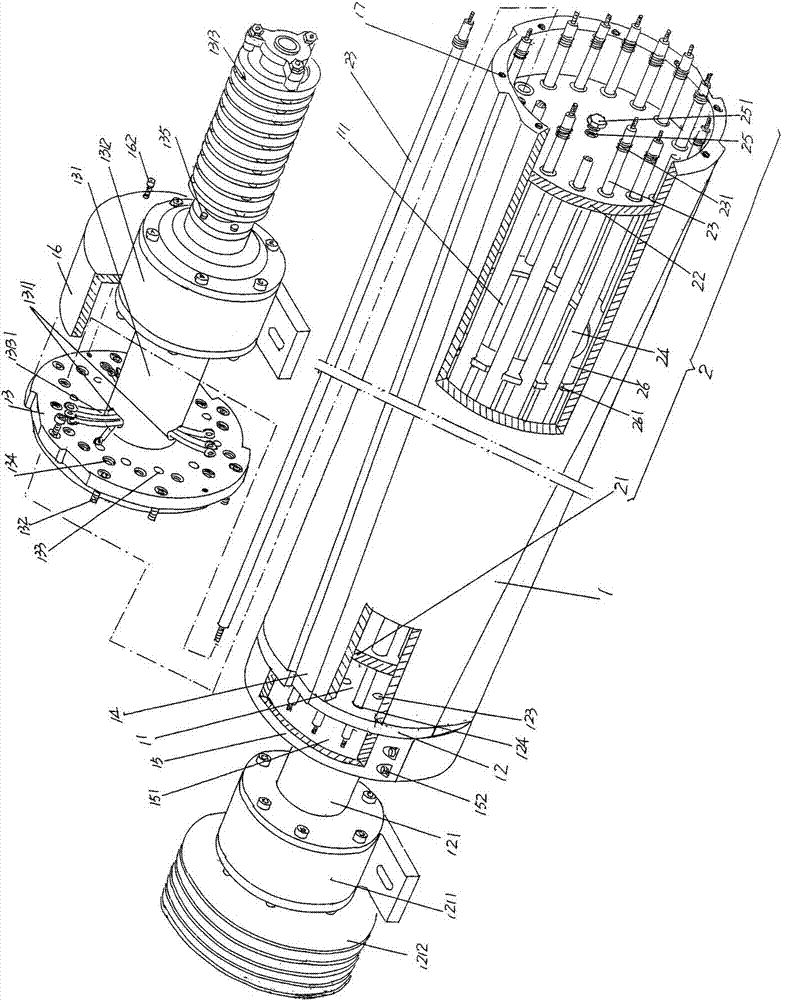

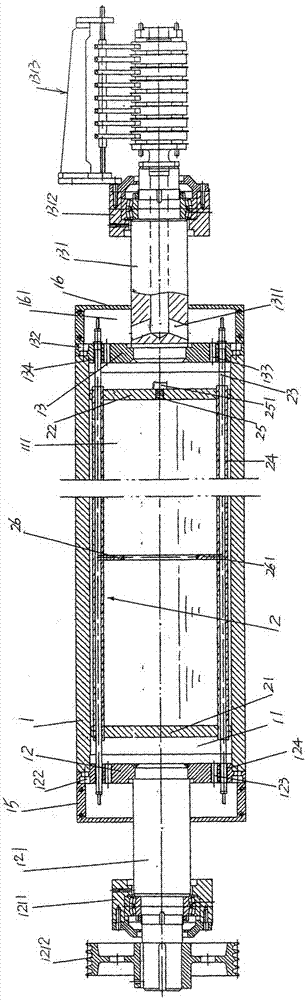

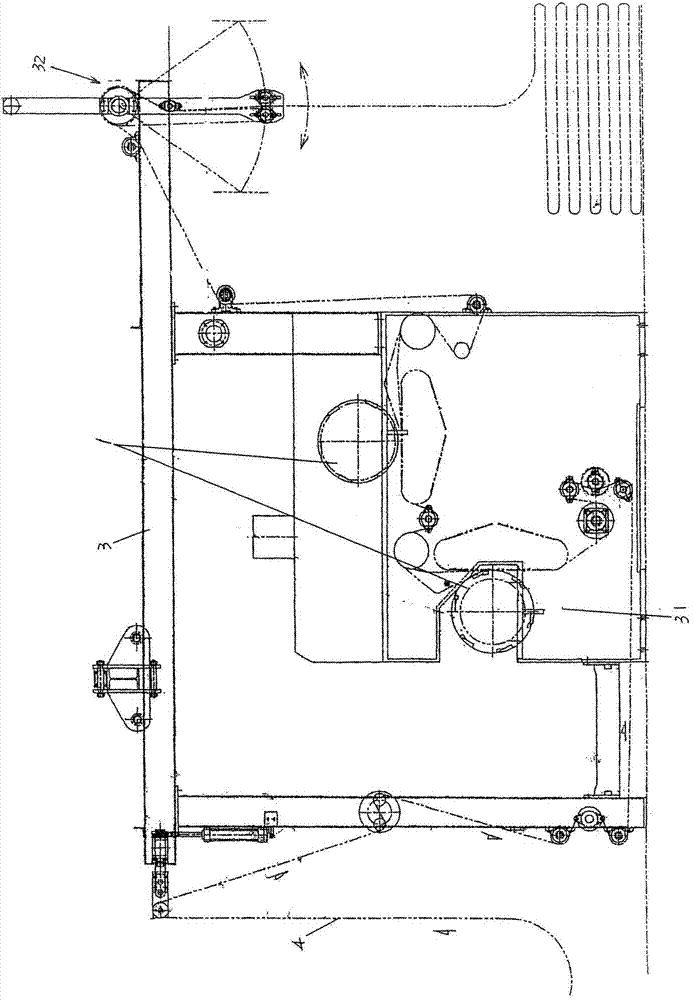

[0028] See figure 1 and figure 2 , a ironing roller body 1 preferably made of a material with good heat transfer effect such as aluminum alloy or other similar materials is given, and the length of the ironing roller body 1 is not necessarily limited in the present invention, because In the actual use process, because the width of the fabric (the industry customarily called the door width) is wide or narrow, such as 2m, 1.8m and 1.5m, etc., the length of the ironing roller body 1 can usually be determined according to the requirements of the textile printing and dyeing enterprise. Ask to be sure.

[0029] At the left end of the aforementioned ironing roller body 1 and at a position corresponding to the left cavity opening of the cavity of the ironing roller body 1, a left shaft head cover 12 is fixed, and the left shaft head cover 12 faces away from the cavity One side of 11, that is, the central position of the left side extends to form a left support shaft head 121, and the...

Embodiment 2

[0041] Only the medium introduction hole 25 is transferred to the left closure cover 21, and the rest are the same as the description of embodiment 1.

Embodiment 3

[0043] Both the left closing cover 21 and the right closing cover 22 are provided with a medium introduction hole 25, and the rest are the same as the description of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com