multifunctional crushing head

A crushing head, multi-functional technology, applied in the direction of earthmoving machine/shovel, construction, etc., can solve the problems of low production efficiency and unsecured safety, so as to improve work efficiency, avoid energy loss, increase high impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

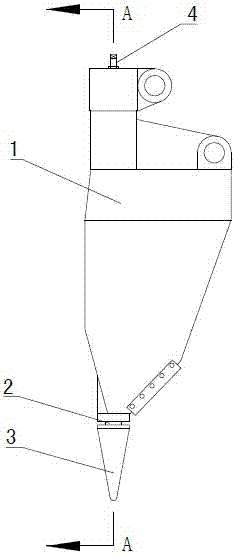

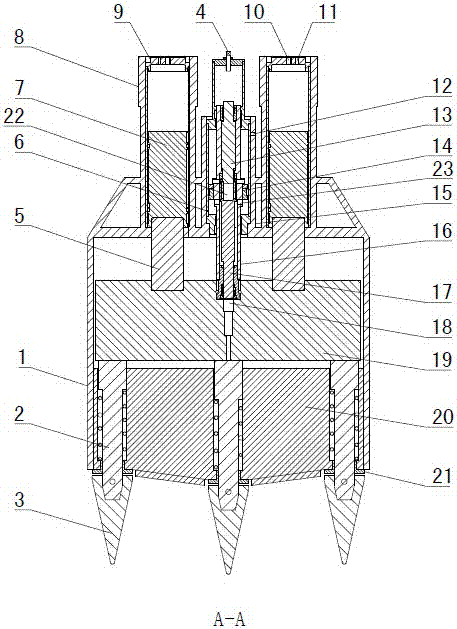

[0024] Figure 1~2 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~2 The present invention will be further described.

[0025] A multi-functional crushing head, including a bucket 1, a power bin on the upper part of the bucket 1, a hammer plate 19 on the lower part of the power bin, and a drill bit 3 installed under the hammer plate 19 through a drill rod 2. The power bin includes an oil cylinder 15 in the middle and two Side cylinder 8. The piston rod 16 of the oil cylinder 15 is a tubular structure, and the piston rod 16 is provided with a quick oil return valve. The lower end of the piston rod 16 is fixedly connected with the hammer plate 19, and the piston rod 16 and the hammer plate 19 are provided with a control mechanism that promotes the opening and closing of the quick oil return valve. The quick oil return valve can make the hydraulic oil in the lower cavity of the piston in the cylinder 15 quickly flow to the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com