Integrated type ultrahigh-pressure booster pump

A technology of ultra-high pressure and booster pumps, applied in the field of hydraulic oil pumps, can solve problems such as low working efficiency, scattered systems of devices, and increased cross-sectional size of pistons, and achieve the advantages of easy transportation and installation, saving installation space, and increasing output pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

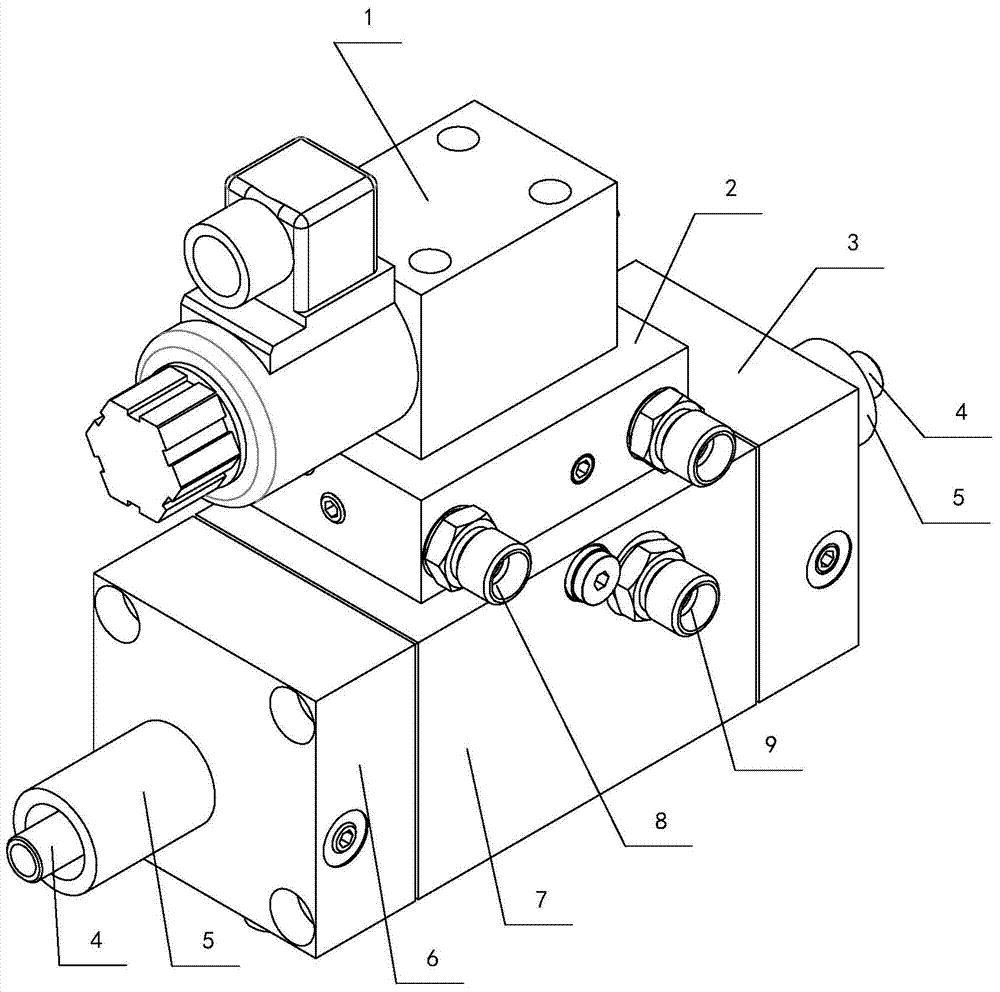

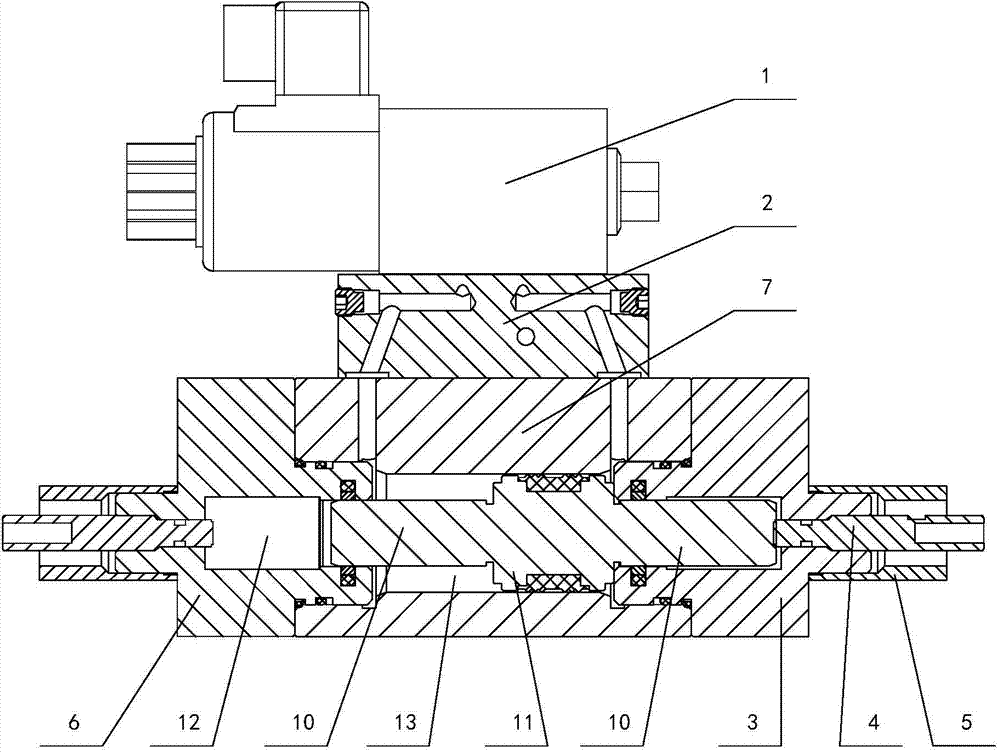

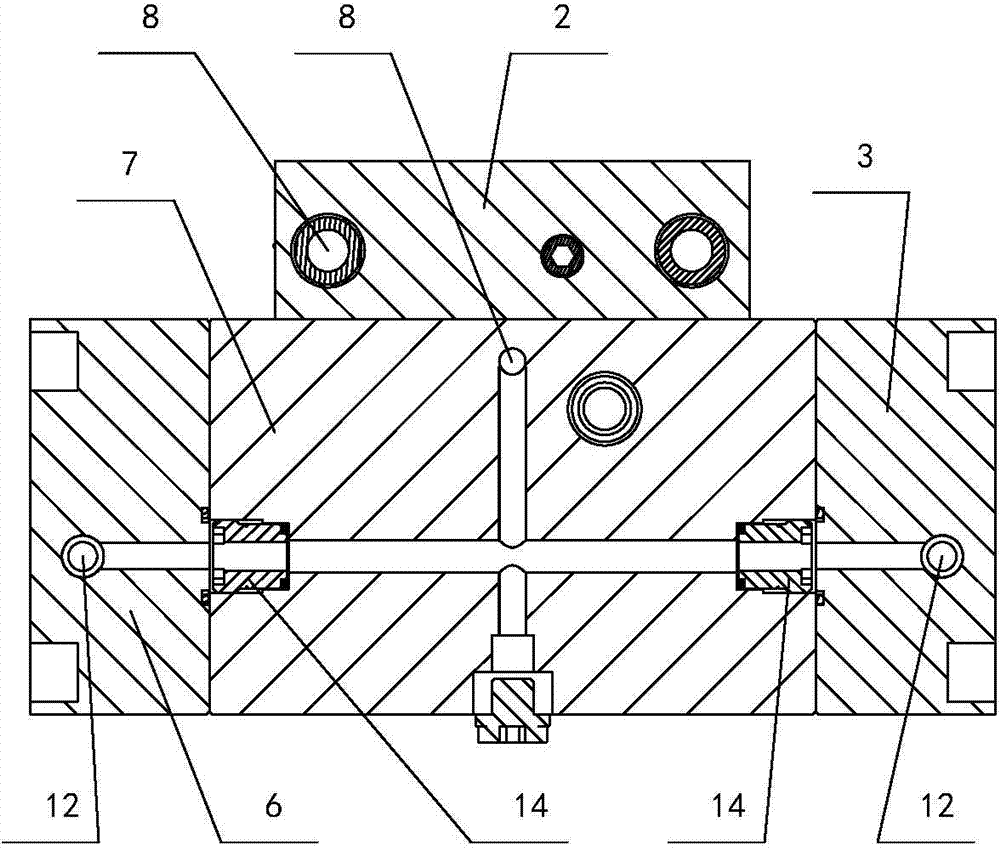

[0028] Depend on Figure 1 to Figure 5It can be seen from the schematic structural diagram and hydraulic schematic diagram of the integrated ultra-high pressure booster pump of the present invention that it includes an oil cylinder barrel 7, a left end cover 6, a right end cover 3, a piston 11 and a piston rod 10. There are two piston rods 10 and They are respectively connected to the two ends of the piston 11, the piston 11 is slidingly connected in the cylinder barrel 7, the left end cover 6 and the right end cover 3 are respectively connected to the left and right ends of the cylinder barrel 7, in other words, the left end cover 6 is connected to the oil cylinder cylinder The left end of barrel 7, the right end cover 3 is connected in the right end of cylinder barrel 7 of oil cylinder. It also includes a proportional solenoid valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com