Ultraviolet detector optical subdivision device

An ultraviolet detector and optical technology, applied in the field of ultraviolet detectors, can solve the problems of inability to maintain the instrument on site, high processing requirements, unfavorable convenience, etc., and achieve the effects of correcting the motor rotation angle, reducing production costs, and optimizing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

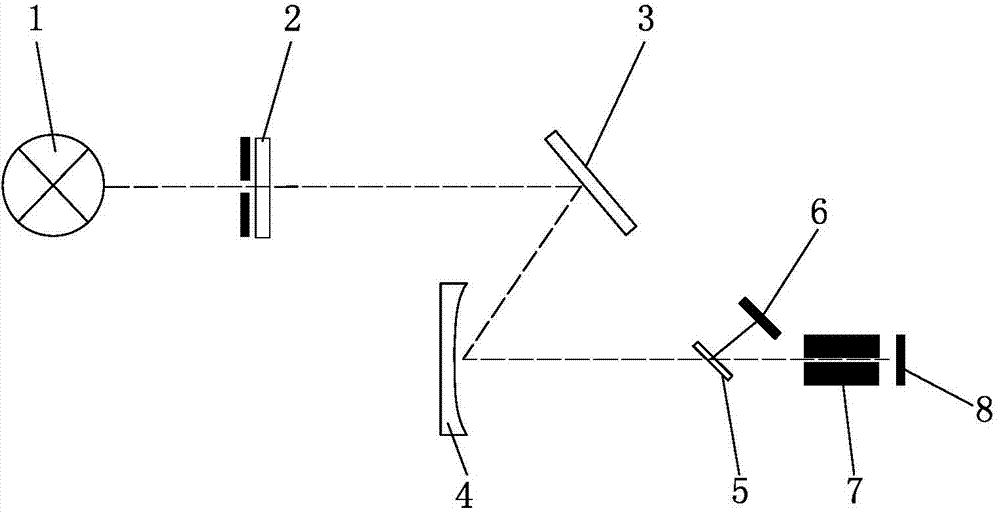

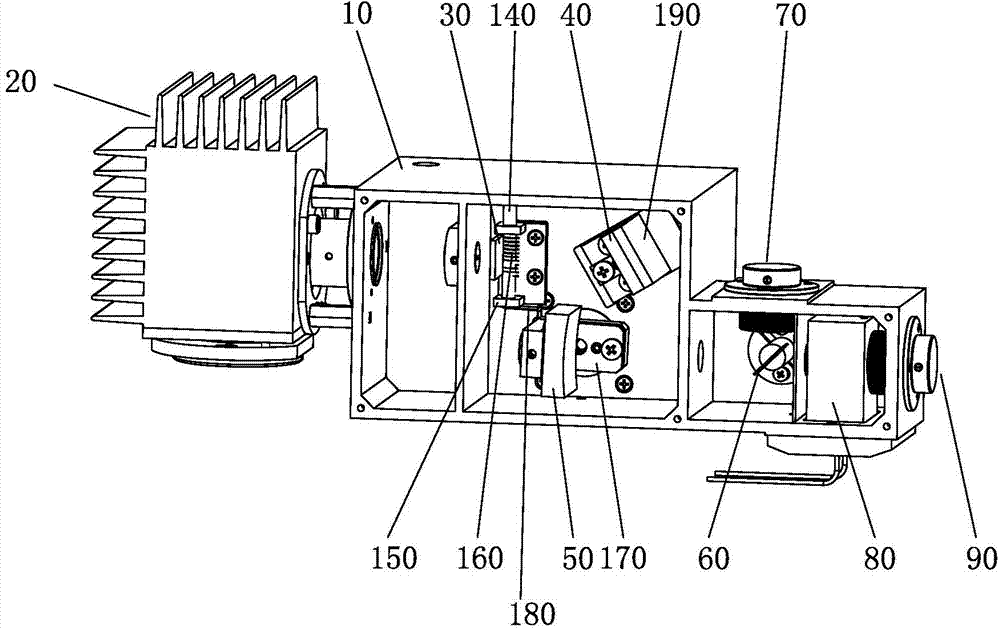

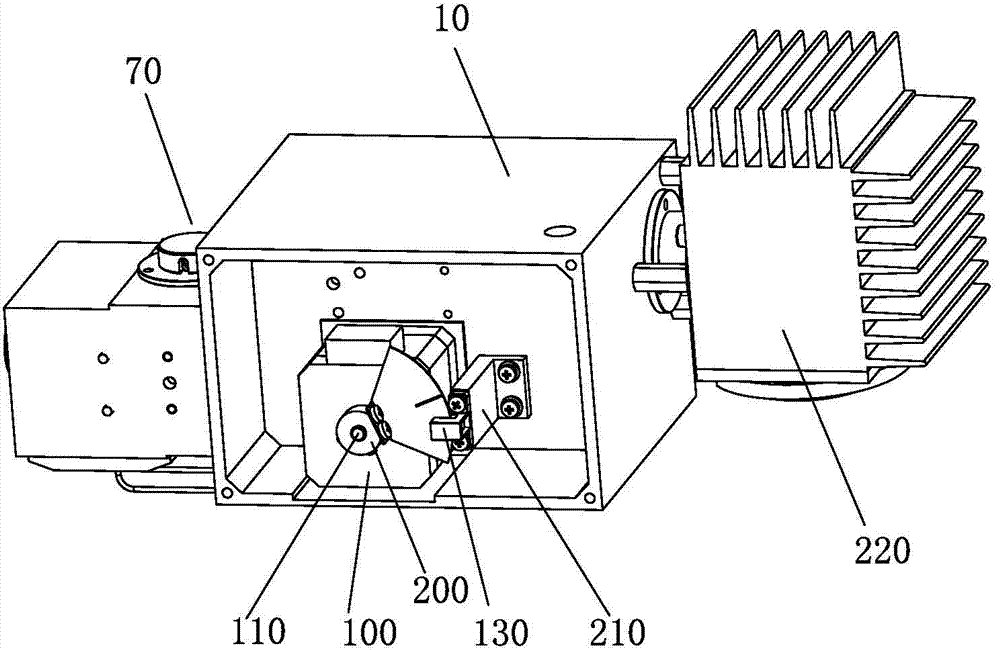

[0023] The present invention will be further described below with specific embodiment, see figure 2 —4:

[0024] An ultraviolet detector optical subdivision device, including a light source 20, a filter 30, a mirror 40, a concave grating 50, a half mirror 60, a reference photocell 70, a flow Through the pool 80 and the sample photocell 90, the light of the lamp source 20 passes through the optical filter mirror 30, the mirror 40, the concave grating 50, the half mirror 60 successively, and passes through the reference photocell 70 and the half mirror 60 respectively from the half mirror 60. Flow through pool 80, sample photocell 90, described grooved grating 80 is driven to rotate by stepper motor 100, is provided with the optocoupler stopper 120 that rotates synchronously with grooved grating 80 on the motor shaft 110, on the optocoupler stopper One side of 120 is provided with an optocoupler 130 that cooperates with the optocoupler block 120 , and each time the power is tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com