Power line inspection method utilizing portable multifunctional intelligent line inspection instrument

A power line inspection, multi-functional technology, applied in overhead lines/cable equipment and other directions, can solve the problems of high instrument price, long time consumption, insufficient distance to the ground, etc., to save manpower and material resources, facilitate rapid completion, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

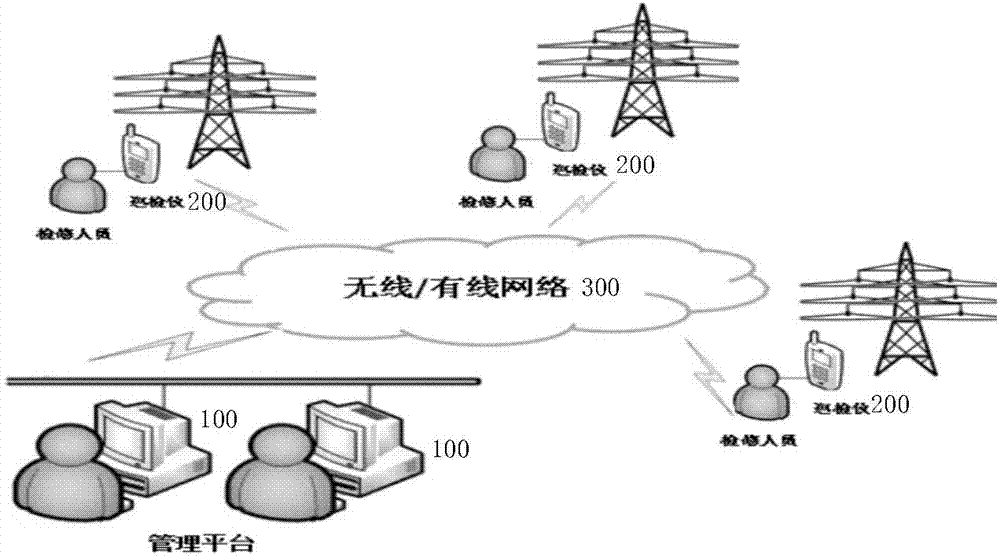

[0035] figure 1 An exemplary system application environment for applying the present invention is shown.

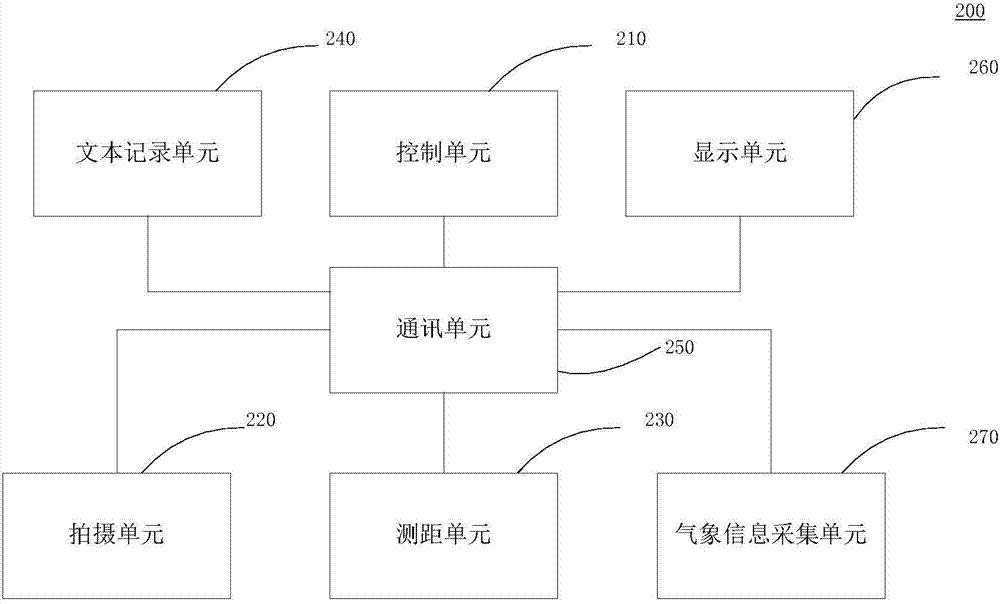

[0036] The whole system is composed of multiple front-end hand-held multifunctional intelligent line inspectors (hereinafter sometimes referred to as inspection instruments) 100 and a central management platform 200 (background server). The multifunctional intelligent line inspectors 100 are carried by the line inspectors Carry and replace traditional cameras, rangefinders, weather instruments, GPS, telescopes and other equipment to collect data and images for line failures or hidden dangers. Each multifunctional intelligent line inspector 100 transmits the information and / or processing results collected by itself to the background management...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com