Adhesives for conduit fixing with window

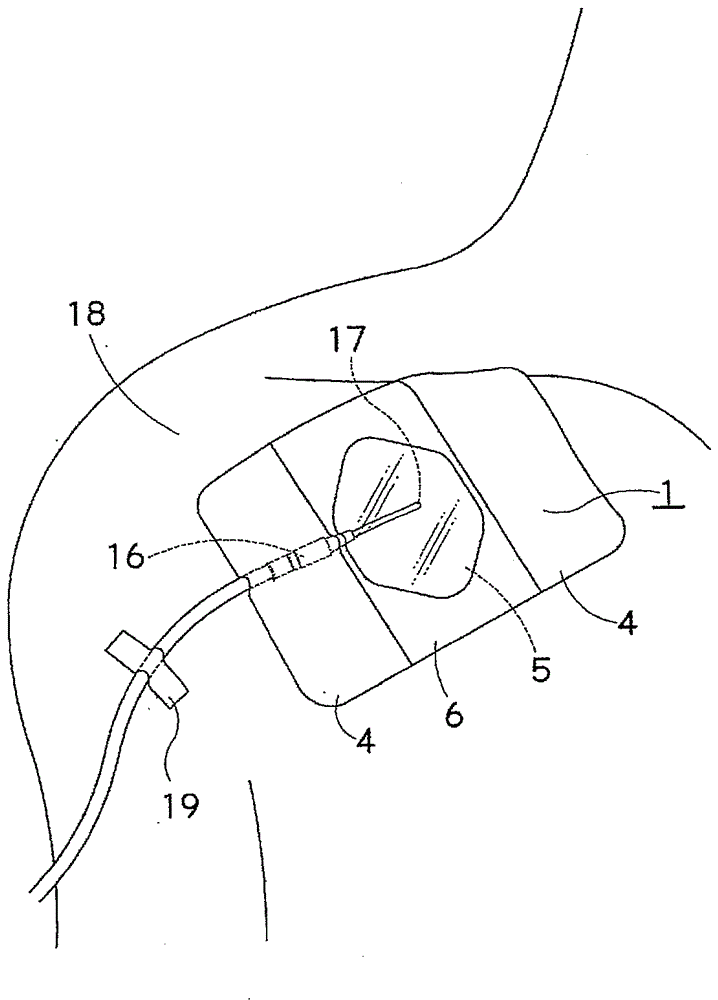

A catheter fixing and sticking technology, which can be applied to catheters, bandages, trocars, etc., and can solve problems such as troublesome sticking operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

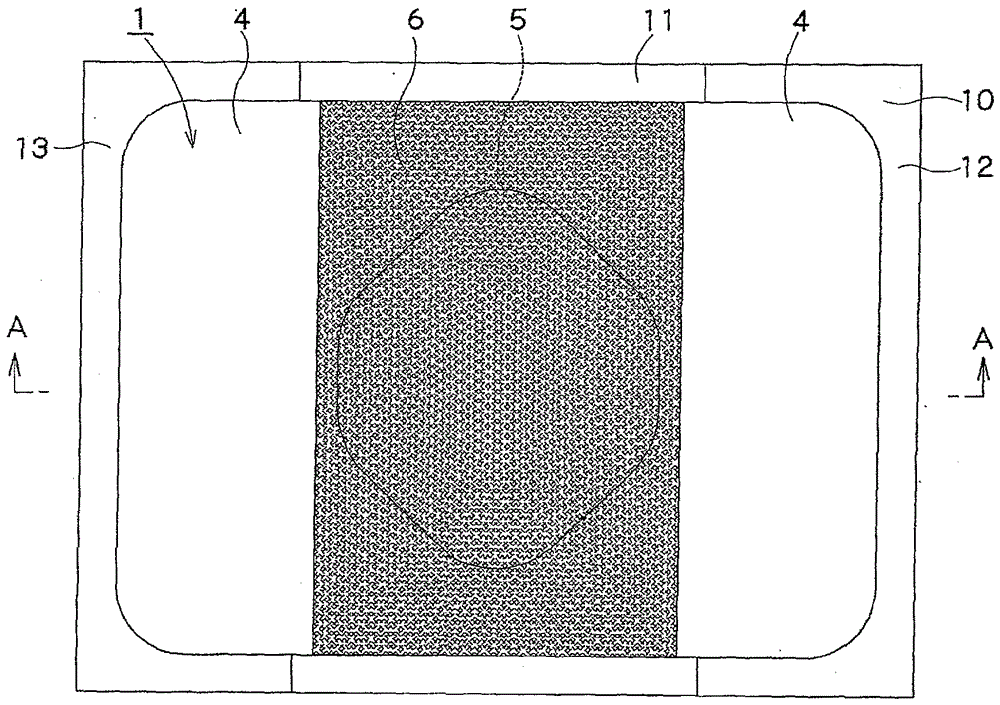

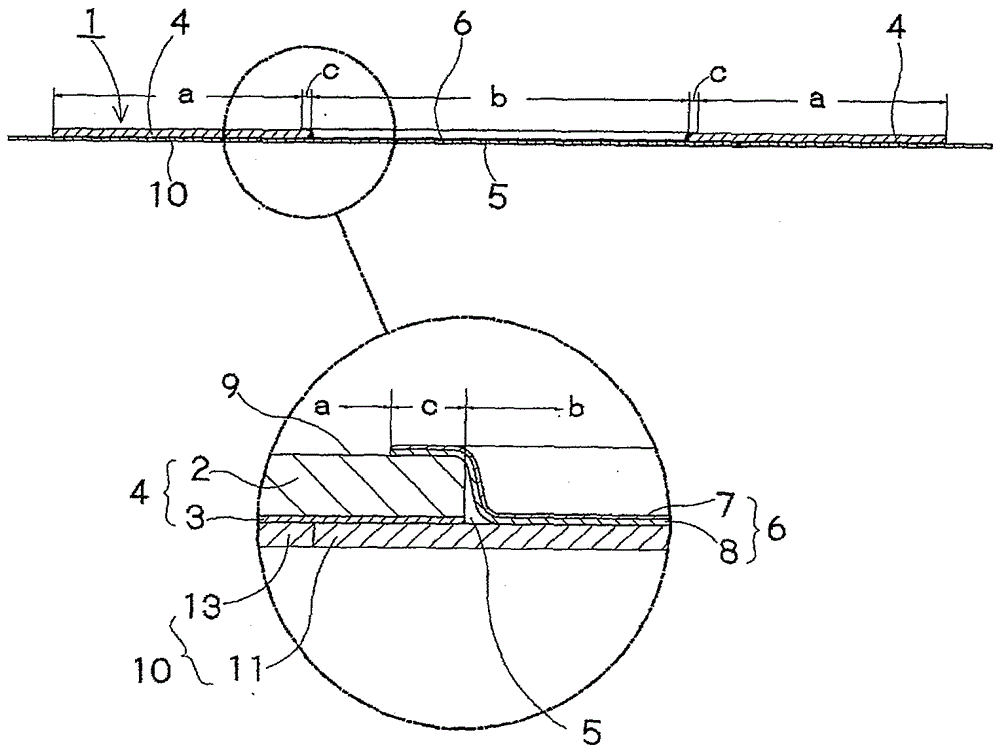

[0064] Prepare a polyurethane non-woven fabric with a thickness of 300 μm and a surface roughness of “26 μm” by extrusion processing so that the surface roughness becomes “11 μm”, and the 30% tensile load is 2.11 N / 15 mm in the width direction and 3.06 in the length direction. N / 15mm polyurethane non-woven fabric 2. An acrylic foamed adhesive layer 3 with a thickness of 30 μm was formed on one side of the nonwoven fabric, and it was formed into a rectangle with rounded corners of 8 cm in length and 11 cm in width. And the rounded hexagonal window part 5 of 5 cm long x 4.5 cm wide is formed in the center part.

[0065] Next, a rectangular window sheet 6 having a length of 8 cm x width of 5 cm and having a polyurethane adhesive layer 8 of 30 μm thick formed on one surface of a 20 μm thick urethane film 7 was prepared. It was pasted and fixed on the other side 9 of the nonwoven fabric 2 (with a surface roughness of 11 μm) so as to cover the above-mentioned window portion 5 , to ...

Embodiment 2)

[0067] Using a polyurethane non-woven fabric with a thickness of 300μm and a surface roughness of "26μm", the surface roughness is "13μm" by extrusion processing, and the 30% tensile load is 1.19N / 15mm in the width direction and 1.63 in the longitudinal direction. N / 15mm polyurethane non-woven fabric 2. Others are the same as in Example 1, and a catheter-fixing sticker 1 with a window is made.

Embodiment 3)

[0069] Using a polyurethane non-woven fabric with a thickness of 300μm and a surface roughness of "26μm", the surface roughness is "13μm" by extrusion processing, and the 30% tensile load is 1.71N / 15mm in the width direction and 2.26 in the longitudinal direction. N / 15mm polyurethane non-woven fabric 2. Also, the adhesive layer 3 is formed of an acrylic adhesive having a higher adhesive force than the adhesive of Example 1. Others are the same as in Example 1, and a catheter-fixing sticker 1 with a window is made.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com