SCR module

一种内燃机、往复活塞的技术,应用在前序部分所述的内燃机系统领域,能够解决高成本、提高内燃机系统成本、易出故障装配花费等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

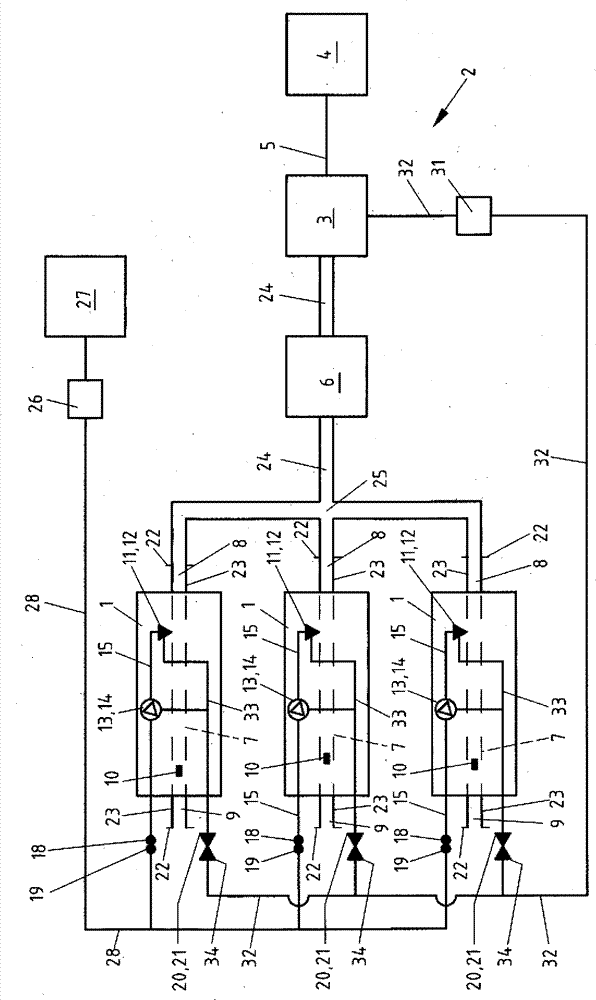

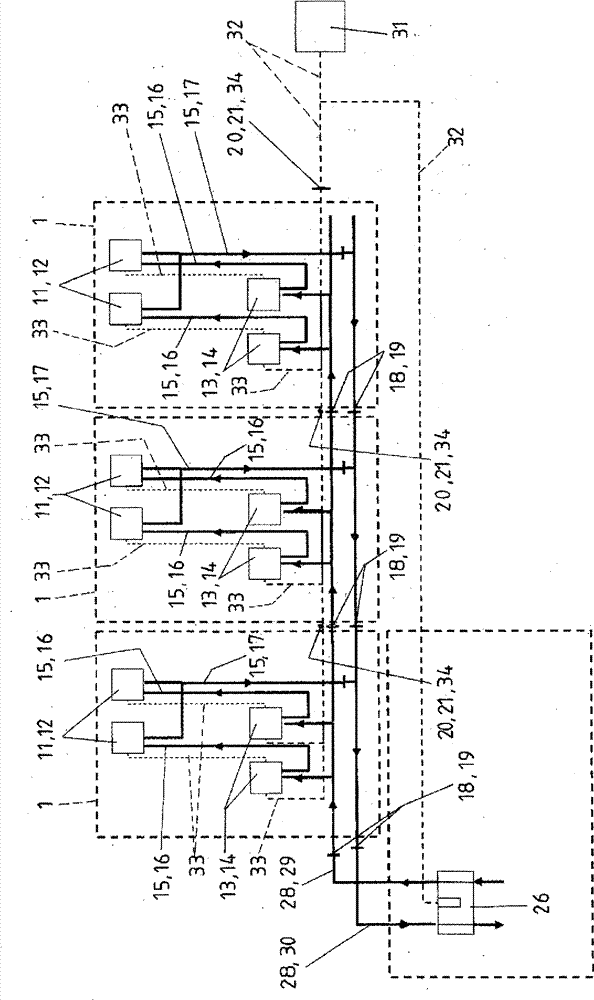

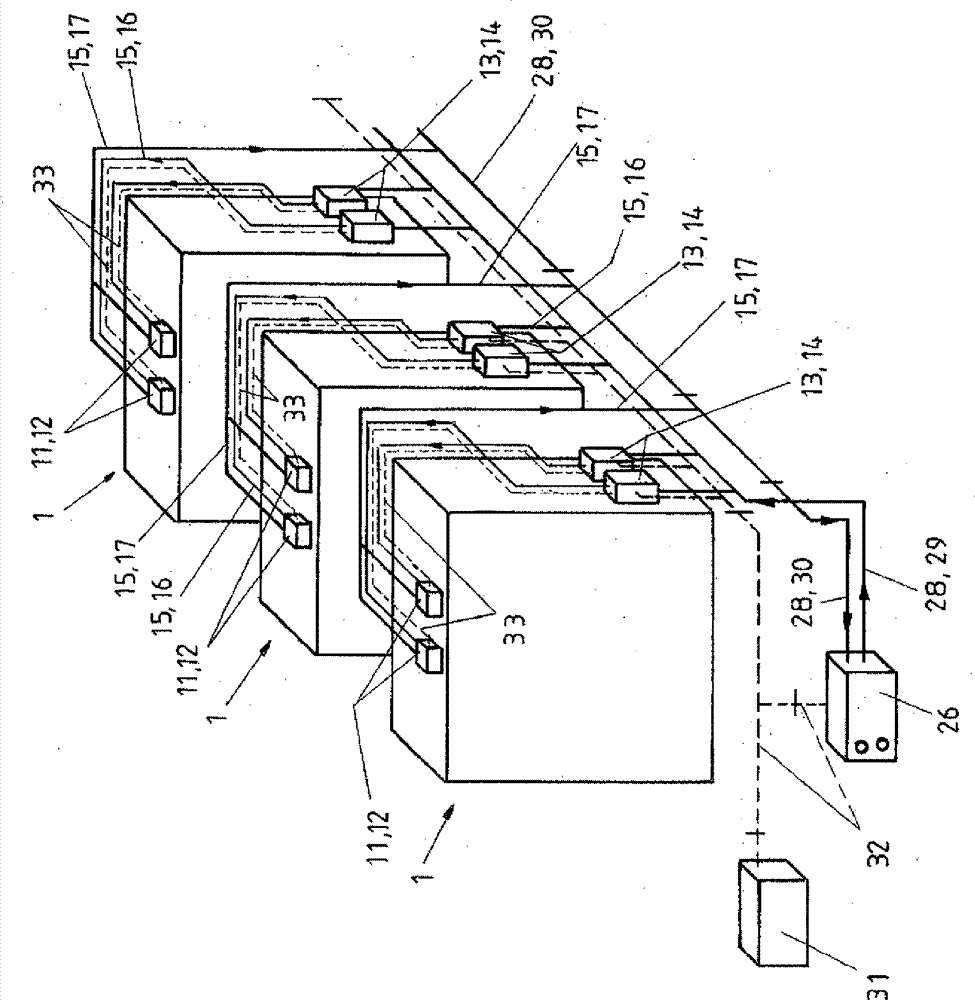

[0032] In addition to the reciprocating piston internal combustion engine 3 as a diesel engine, in image 3 The internal combustion engine system 2 shown in the figure also includes a generator 4 , which is driven by means of a drive shaft 5 of a reciprocating internal combustion engine 3 . The internal combustion engine system 2 is therefore a stationary device and is used to generate electricity. In contrast to this, the internal combustion engine system 2 can also be used in mobile installations without a generator 4 , for example for driving ships, military vehicles (eg armored vehicles) or for driving agricultural vehicles.

[0033] Furthermore, internal combustion engine system 2 includes a particle filter 6 and three SCR modules 1 . The exhaust gas flowing out of the reciprocating internal combustion engine 3 is first conducted via the exhaust gas line 24 through the particle filter 6 in order to separate the particles there, and then it is conducted from the particle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com