Plant destructive distillation liquid, its preparation and its application in improvement of content of effective components in hairy root of Salvia miltiorrhiza

A technology of dry distillate and hairy root, which is applied in the fields of environment and plant active ingredient extraction, to achieve the effects of easy implementation, increased content of medicinal ingredients, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

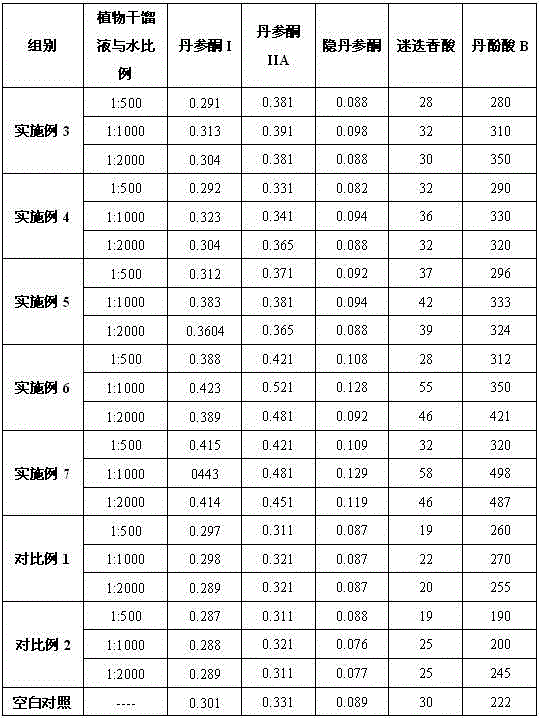

Examples

Embodiment 1

[0025] Take 2kg of hawthorn kernels, wild jujube kernels and walnut shells respectively, add them to the retort with a mass ratio of 1:1:1, heat to 140-145°C, keep warm for 1 hour, continue to heat to 240-245°C, keep warm for 2 hours, and then the temperature Rise to 300-360°C and maintain for 1 hour. Collect the dry distilled liquid at each time period, mix and stir for 30 minutes, transfer to a separatory funnel and let stand for 12 hours, and separate the supernatant. Add the supernatant to the distillation pot, distill at 100-105°C for 2 hours, and collect the distillate. Add 10wt% activated carbon to the distillate, stir and heat to 95°C, keep for 45 minutes, filter, and collect the filtrate. The filtrate is the plant dry distillate of the present invention.

Embodiment 2

[0027] Take 1 kg of hawthorn kernels, wild jujube kernels and walnut shells respectively, add them to the retort with a mass ratio of 1:1:1, heat to 140-145°C, keep warm for 1 hour, continue to heat to 240-245°C, keep warm for 2 hours, and then The temperature was raised to 300-360°C and maintained for 1 hour. Collect the dry distilled liquid at each time period, mix and stir for 30 minutes, transfer to a separatory funnel and let stand for 12 hours, and separate the supernatant. Add the supernatant to the distillation pot, distill at 100-105°C for 2 hours, and collect the distillate. Add 10wt% activated carbon to the distillate, stir and heat to 95°C, keep for 45 minutes, filter, and collect the filtrate. The filtrate is the plant dry distillate of the present invention.

Embodiment 3

[0029] Take a total of 1.5kg of hawthorn core, wild jujube core and walnut shell, put them into the retort at a mass ratio of 1:1:1, heat to 140-145°C, keep warm for 1 hour, continue to heat to 240-245°C, keep warm for 2 hours, Then the temperature was raised to 300-360° C. for 1 hour. Collect the dry distilled liquid at each time period, mix and stir for 30 minutes, transfer to a separatory funnel and let stand for 12 hours, and separate the supernatant. Add the supernatant to the distillation pot, distill at 100-105°C for 2 hours, and collect the distillate. Add 10wt% activated carbon to the distillate, stir and heat to 95°C, keep for 45 minutes, filter, and collect the filtrate. The filtrate is the plant dry distillate of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com