Method for controlling ferritic stainless steel tail billet width

A stainless steel and ferrite technology, which is used in the field of controlling the width of stainless steel tail blanks, and can solve the problems of large target width tolerance and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

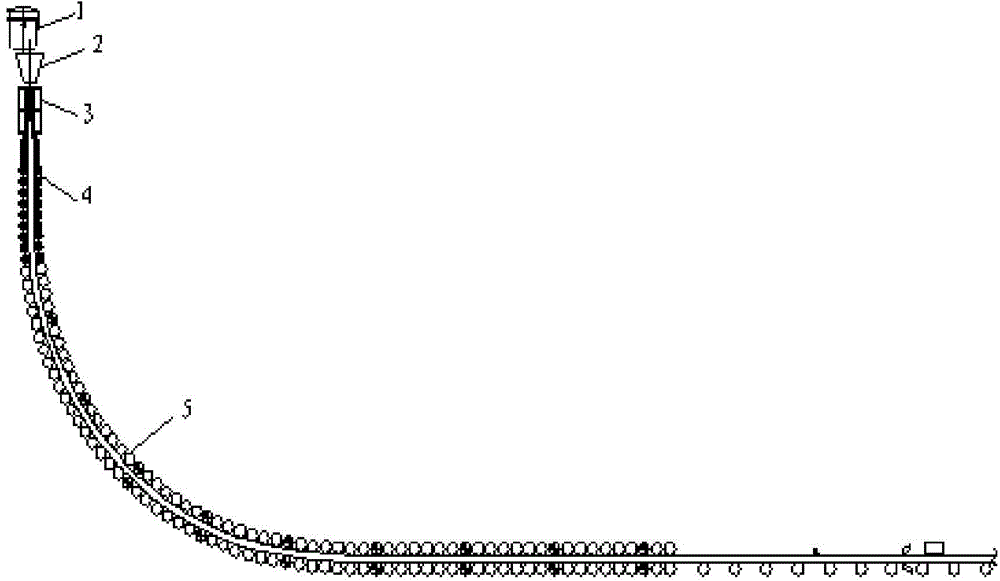

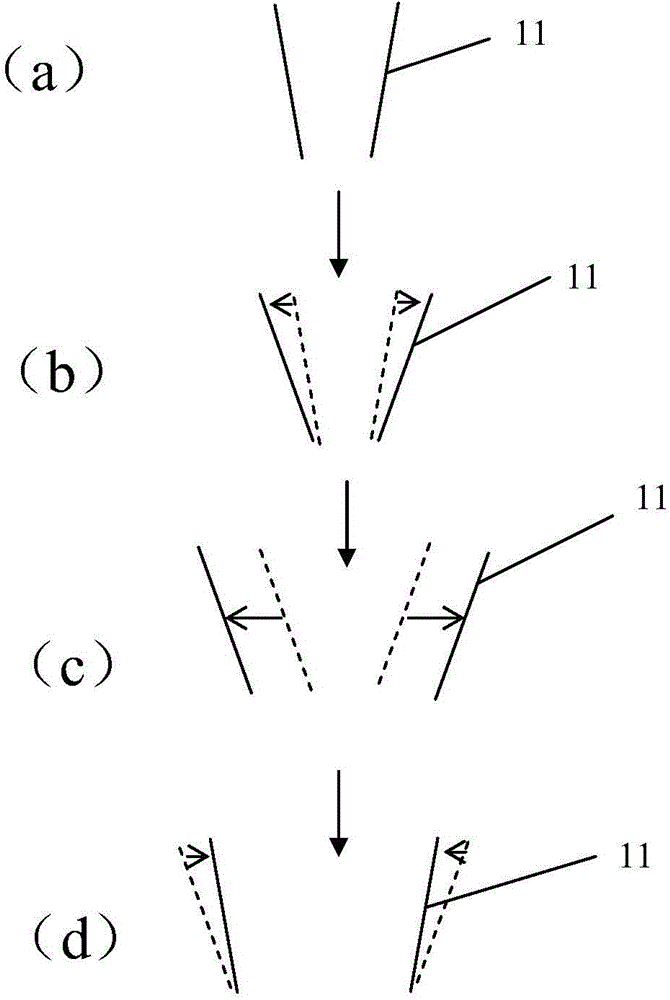

[0036] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings of the embodiments.

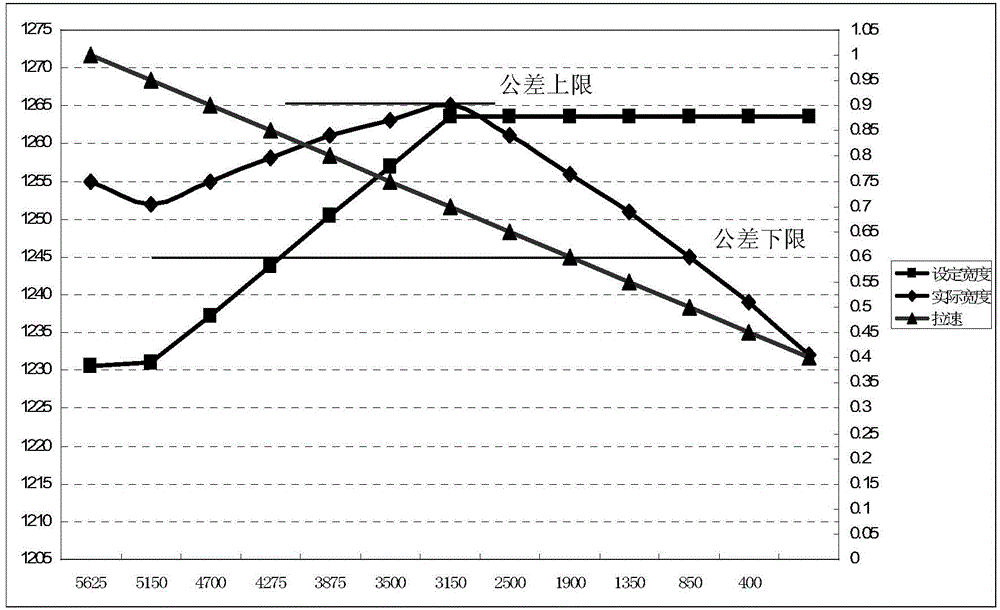

[0037] The current steel mills have strict control on the width tolerance of the slab. The enterprise standard, industry standard and national standard of the slab have strict regulations on the width of the slab. Generally, the width tolerance of the cast slab is required to be ±10mm, that is, the actual Width W actual with target width W aim must satisfy the following relationship:

[0038] W aim -10mm≤W actual ≤W aim +10mm Formula (3)

[0039] As the pulling speed gradually decreases during the finishing process, the actual width W actual It will be narrowed beyond the negative tolerance requirement. Therefore, in order to make the tail slab meet the requirements, the continuous casting side can only cut the slab to ensure that the width of the tail of the slab is ≥W aim -10mm; this will generate a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com