Hydraulic automatic coupler lifting device for empty car shunting machine and control method

An empty car shunting machine, hydraulic technology, applied in the direction of railway vehicle traction device, transportation and packaging, railway car body parts, etc. The problems such as imperfect head interlocking device and the carriage falling into the foundation pit of the relocation platform, etc., achieve the effect of obvious long-term benefits, compact and reasonable structure and location, and small occupied space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

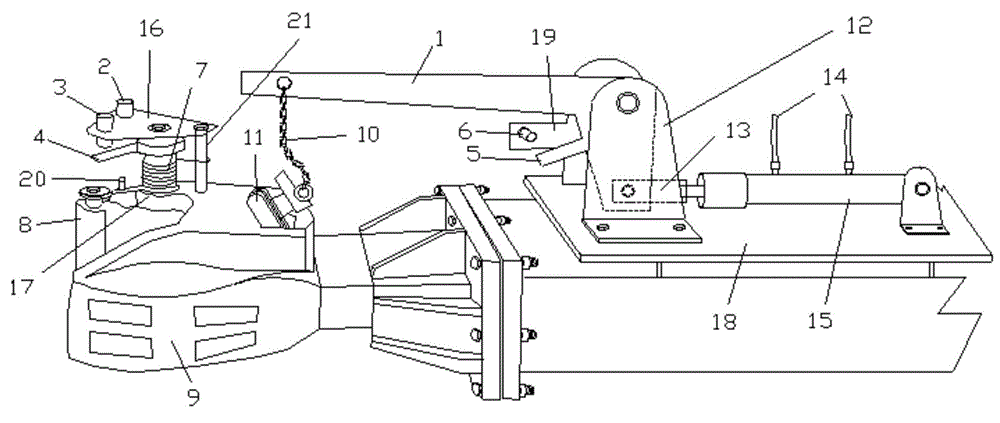

[0031] A hydraulic automatic hook lifting device and control method for an empty car shunting machine of the present invention will be further described below in conjunction with the accompanying drawings and examples:

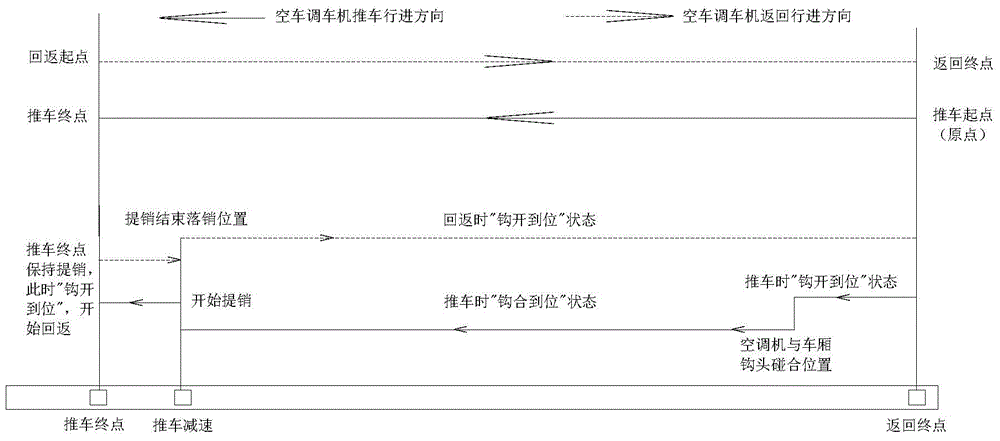

[0032] Such as figure 1 , figure 2As shown, a hydraulic automatic hook lifting device for an empty car shunting machine includes a pin lifting and hook opening control mechanism and a positioning detection mechanism. The hook lifting control mechanism includes a hook head 9 and a hook connected to the hook head 9 through a pin shaft. Tongue 8, the hook control mechanism also includes a pin lifting rod 1, a pin lifting guide chain 10, a cylinder push rod 13, a pin lifting cylinder 15 and an upper lock pin 11; a control knuckle is installed at the upper lock pin hole of the hook head 9 8. Open and close the upper lock pin 11, the pin lifting rod 1 is connected with the upper locking pin 11 through the pin lifting guide chain 10, the root of the pin lifting rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com