An automatic spinning control system for spinning cans and its control method

An automatic threading and control system technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of low degree of automation, many manpower, and affecting yarn quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

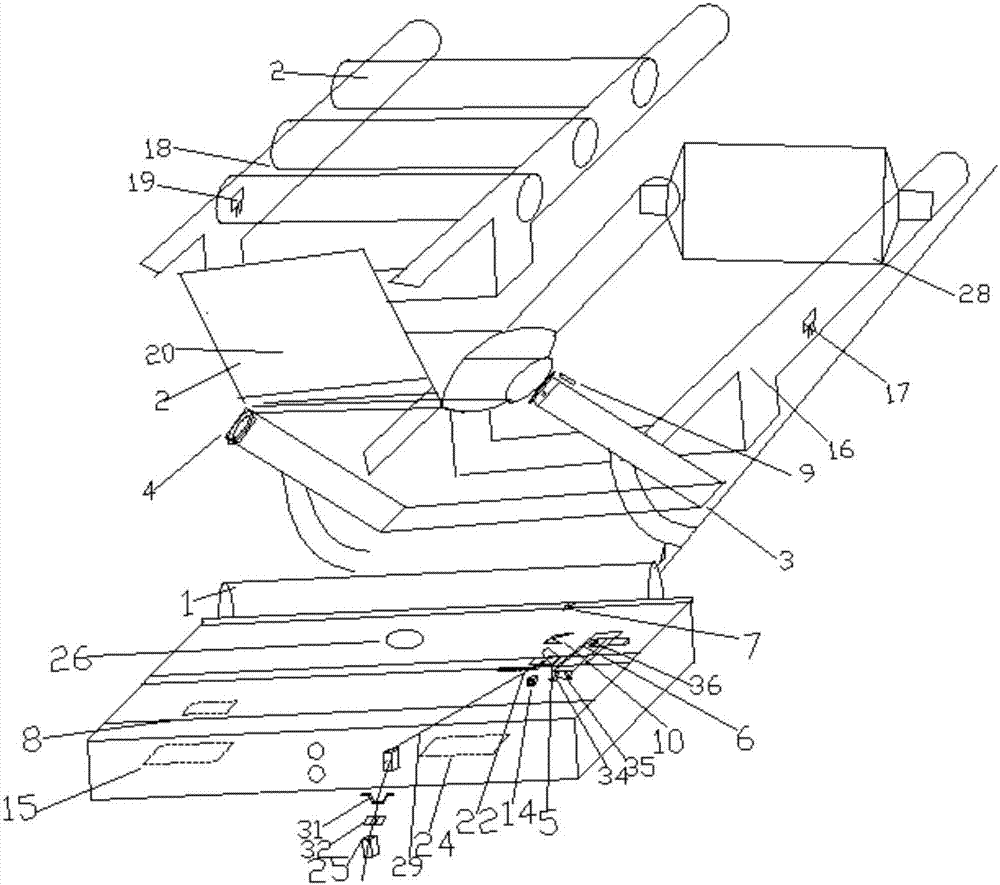

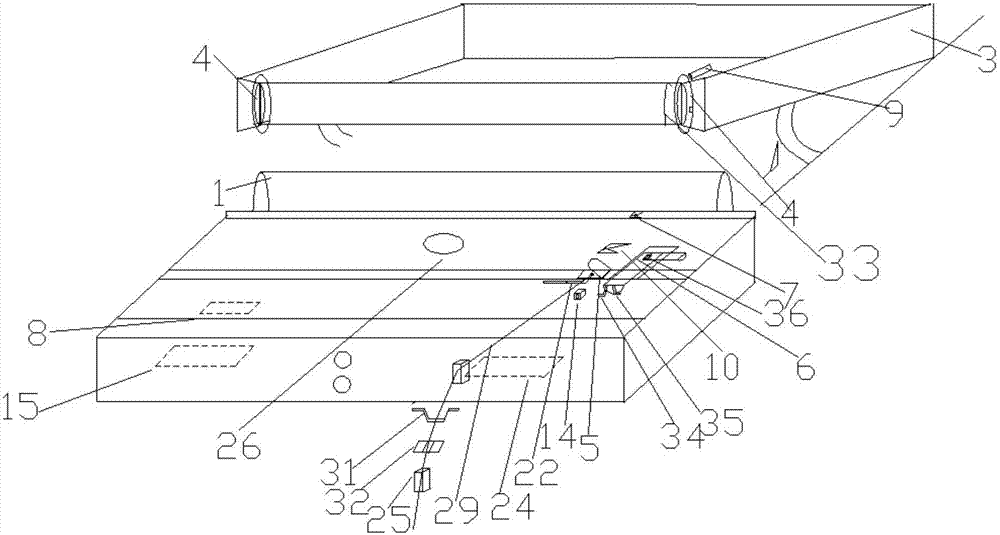

[0017] Embodiment: A kind of control system for spinning automatic tube changer, including black roller 1, traverse yarn guide 7 that drives the yarn to and fro along the length direction of black roller 1, and an empty silo located behind and above black roller 1 18. The empty silo rocker 20 matched with the empty silo 18, the bobbin holder 3 located between the empty silo rocker 20 and the black roller 1 and moving between the first position and the second position, the bobbin The back of the frame 3 is parallel to the full silo 16 of the empty silo 18. The bobbin frame 3 is provided with a chuck 4 for clamping bobbins. 3. Chuck 4 loosens the full yarn bobbin and makes it fall into the full silo 16, receives and clamps the empty bobbin 2 transported by the rocker arm 20 of the empty silo. When the bobbin holder 3 is in the second position, the bobbin The frame 3 holds the empty bobbin 2 in contact with the black roller 1 and rotates to wind the wire. It also includes a wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com