Soluble polymerized sulphur production process and equipment

A technology of polymerizing sulfur and production technology, which is applied in the chemical industry, can solve the problems of not being able to meet the technical requirements of manufacturing high-quality tires, non-blooming, poor thermal stability, affecting the pass rate and safety of tires, etc., and achieve excellent non-blooming properties, excellent high temperature stability, and high conversion rate of sulfur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

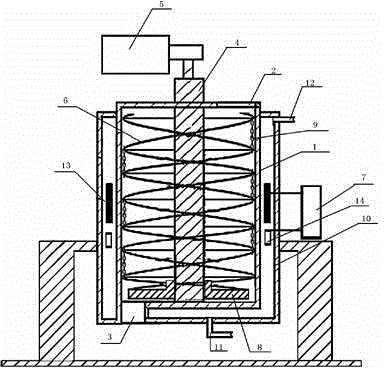

Image

Examples

example 1

[0026] Example 1. The present invention adopts the following steps to complete:

[0027] Prepare the premix

[0028] one. Set the stirring frequency of mixing reactor A to 20Hz, turn on the stirring switch and stir for 8min; put 30 kg of sulfur powder into mixing reactor A, increase the speed to 30Hz, stir for 12min, and mix 2.5 kg of anilinomethyl triethoxy Put γ-(methacryloyloxy)propyltrimethoxysilane and 3.3 kg of γ-(methacryloyloxy)propyltrimethoxysilane into reaction kettle A and stir for 1.5h. The material is released and bagged for use;

[0029] two. Preparation of finished materials

[0030] 1. Set the stirring frequency of mixing reactor B to 20Hz, and the heating water temperature to 98°C, turn on the stirring switch and heating switch of reactor B, and turn it for 10 minutes;

[0031] 2. Put 70 kg of sulfur powder into reaction kettle B, stir for 5 minutes, then put in 37 kg of premix and 2.7 kg of 2-(2,4-dinitrophenylthio)benzothiazole, 2.5 kg of 2-thiolthiaz...

example 2

[0036] Example 2. The present invention adopts the following steps to complete:

[0037] Prepare the premix

[0038] one. Set the stirring frequency of mixing reactor A to 20Hz, turn on the stirring switch and stir for 12min; put 30 kg of sulfur powder into mixing reactor A, increase the speed to 30Hz, stir for 8min, and mix 2.2 kg of anilinomethyltriethoxy Put γ-(methacryloyloxy)propyltrimethoxysilane and 3.7 kg of γ-(methacryloyloxy)propyltrimethoxysilane into reaction kettle A and stir for 1.5h. The material is released and bagged for use;

[0039] two. Preparation of finished materials

[0040] 1. Set the stirring frequency of mixing reactor B to 20Hz, set the heating water temperature to 92°C, turn on the stirring switch and heating switch of reactor B, and turn it for 10 minutes;

[0041] 2. Put 70 kg of sulfur powder into reaction kettle B, stir for 5 minutes, then put in 35 kg of premix and 3 kg of 2-(2,4-dinitrophenylthio)benzothiazole, 2.2 kg of 2-thiolthiazoli...

example 3

[0046] Example 3. The present invention adopts the following steps to complete:

[0047] Prepare the premix

[0048] one. Set the stirring frequency of the mixing reactor A to 20Hz, turn on the stirring switch and stir for 10min; put 30 kg of sulfur powder into the mixing reactor A, increase the speed to 30Hz, stir for 10min, and mix 2.38 kg of anilinomethyltriethoxy Put γ-(methacryloyloxy)propyltrimethoxysilane and 3.62 kg of γ-(methacryloyloxy)propyltrimethoxysilane into reaction kettle A and stir for 1.5h. The material is released and bagged for use;

[0049] two. Preparation of finished materials

[0050] 1. Set the stirring frequency of mixing reactor B to 20Hz, and the heating water temperature to 95°C, turn on the stirring switch and heating switch of reactor B, and turn it for 10 minutes;

[0051] 2. Put 70 kg of sulfur powder into reaction kettle B, stir for 5 minutes, then put in 36 kg of premix and 28.5 kg of 2-(2,4-dinitrophenylthio)benzothiazole, 2.38 kg of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com