Purification method for 5-grade grains of lotus root starch

A purification method, the technology of lotus root starch, is applied in the field of purification of starch granules of different sizes, which can solve the problems of starch granule shape, uneven size, low purity, etc., and achieve the effects of low cost, simple operation, and improved accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

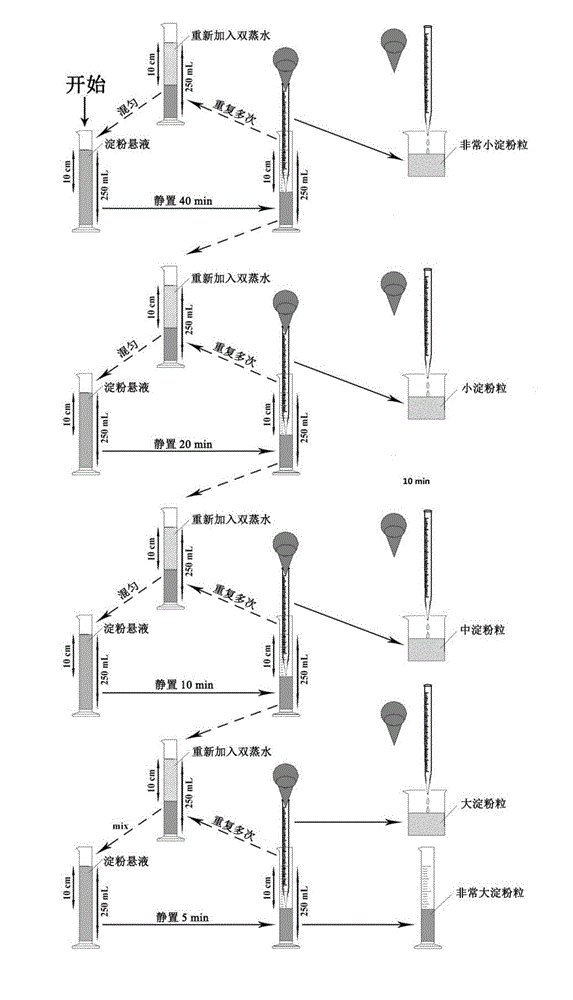

[0046] Embodiment: (the flow process of whole purification process sees figure 1 )

[0047] (1) Purification of very small starch granules:

[0048] ①Preparation of starch suspension: Weigh 2.5g of lotus root raw starch into a 250mL graduated cylinder, add 250mL of double-distilled water, and make an aqueous suspension with a concentration of 1%.

[0049] ② Mixing: Take a rubber sheath, put it on the mouth of the measuring cylinder to ensure the seal, press the mouth of the measuring cylinder with the palm of the right hand, grasp the bottom of the measuring cylinder with the left hand, turn the measuring cylinder upside down 10 times, fully mix the suspension, and take off the leather sheath.

[0050] ③Stationary settlement: place the measuring cylinder on a horizontal table, after settling for 40 minutes, extend the bottom of the 25mL pipette to 1cm below the liquid surface, carefully draw the supernatant into a beaker, repeat several times until the supernatant is complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com