Silicone-modified epoxy resin and synthesis method as well as method for alleviating luminous attenuation with silicone-modified epoxy resin

A technology of epoxy resin and synthesis method, which is applied in the field of materials, can solve the problems of high hygroscopicity and poor flexibility of epoxy resin, and achieve the effects of low cost, easy operation and obvious improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

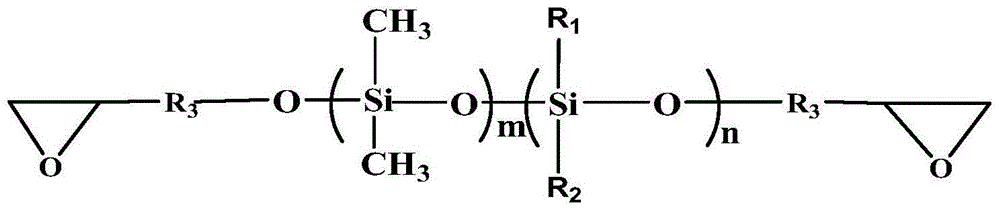

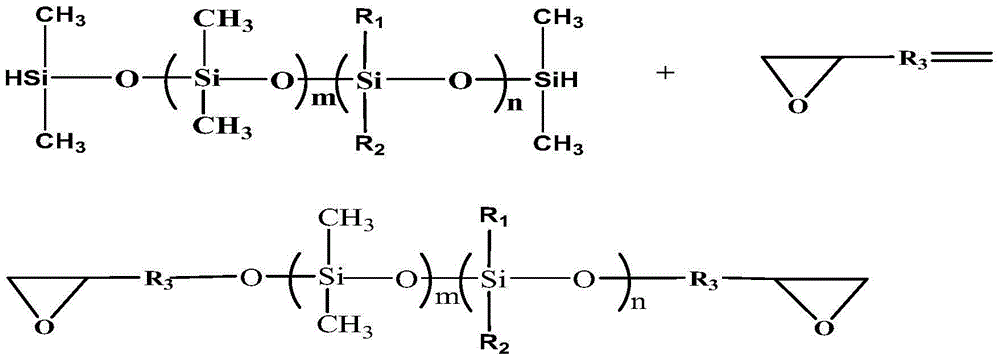

[0025] A kind of synthetic method of organosilicon modified epoxy resin, comprises the steps:

[0026] (1) In an oil bath at 80-120°C, add a double bond-containing epoxy monomer to the phenyl hydrogen-containing silicone oil, and add a catalyst; the double bond-containing epoxy monomer is methacrylic acid shrinkage One or more of glycerol esters, 3,4-epoxycyclohexyl methyl methacrylate, and 1,2-epoxy-4-vinylcyclohexane. The hydrogen content of the phenyl hydrogen-containing silicone oil is 0.7%. The catalyst is a platinum catalyst, the content is 1000PPM-5000PPM, and the added amount is 5% of the total amount. The weight ratio between the phenyl hydrogen-containing silicone oil and the epoxy monomer containing double bonds is 1:1.

[0027] (2) Stir while adding dropwise, and the dropwise addition time is controlled at about 2-3h;

[0028] (3) Continue to react after dripping, and detect repeatedly until the infrared spectrum detects that the Si-H characteristic peak disappe...

Embodiment 1

[0037] 1. Add 1,2-epoxy- Add 5% catalyst (1000PPM) to 4-vinylcyclohexane; the adding process is to stir while dripping in an oil bath at 80°C, and the dripping time is controlled at about 3h; after the dripping, continue the reaction until the infrared Spectral detection Si-H characteristic peak disappears completely, then stop reaction. The obtained product is a silicone-modified epoxy resin.

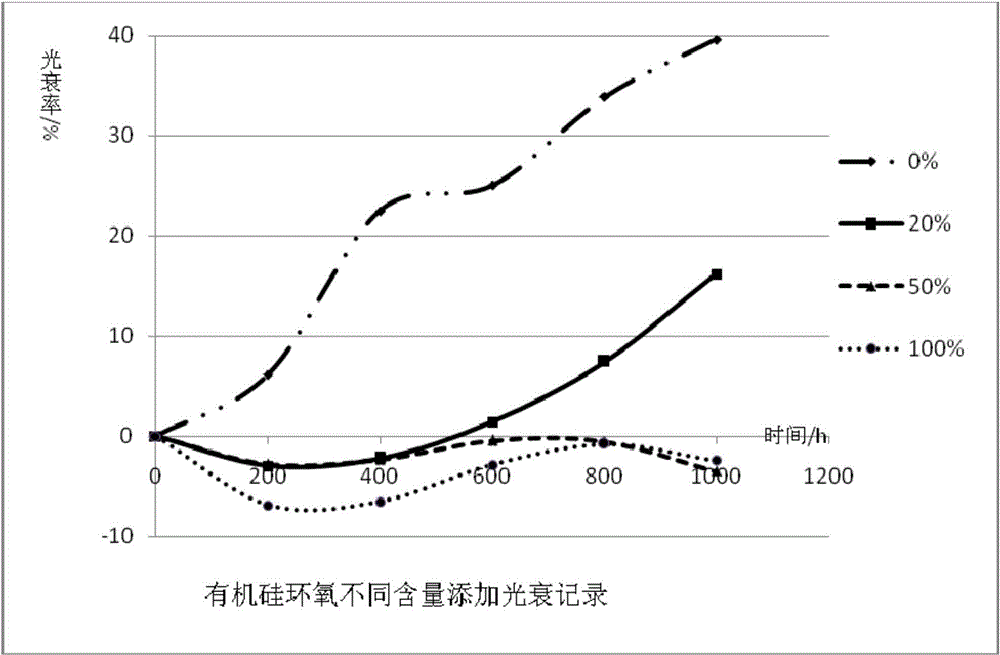

[0038] 2, the organosilicon epoxy resin that is synthesized is added in the bisphenol A type epoxy resin with the ratio of 0%, 20%, 50%, 100% respectively to form A agent, and B agent anhydride (weight percent is 70% formazan Base hexahydrophthalic anhydride (composed of 30% hexahydrophthalic anhydride) is cured on the patch, the curing condition is 135°C*1h+150°C*4h, the patch type is 5050, the lighting current is 3*30mA, every 200h Measure the luminous flux, light up for 1000h in total.

[0039] It was found that with the increase of the addition of new silicone epoxy resin, the i...

Embodiment 2

[0041] 1. Press "double bond-containing epoxy monomer": "phenyl hydrogen-containing silicone oil" = 1:1, add glycidyl methacrylate to 0.7% hydrogen-containing phenyl hydrogen-containing silicone oil, and add 5% catalyst (1000PPM); the adding process is to stir while dripping in an oil bath at 120°C, and the dripping time is controlled at about 3h; Stop responding. The obtained product is a silicone-modified epoxy resin.

[0042] 2. Add the synthesized organosilicon epoxy to the bisphenol A type epoxy resin in proportions of 0%, 20%, 50%, and 100% respectively to form A agent, and B agent anhydride (70% by weight is methyl Hexahydrophthalic anhydride (composed of 30% hexahydrophthalic anhydride) is cured on the patch, the curing condition is 135°C*1h+150°C*4h, the patch type is 5050, the lighting current is 3*30mA, measured every 200h Luminous flux, a total of 1000h lit.

[0043] It was found that with the increase of the amount of the new silicone epoxy resin, the improveme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com