Mulberry beer and preparation technology thereof

A preparation process and technology of beer, which is applied in the field of beer, can solve problems such as inappropriateness, and achieve the effects of strong effect, improved utilization rate, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

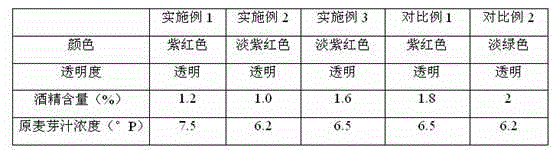

Embodiment 1

[0019] A mulberry beer comprising the following raw materials by mass percentage: 10% mulberry extract, 14.6% corn, 48% wheat germ, 0.4% honeysuckle extract, 5% glucose, 0.6% hops, 1.4% yeast, and 20% water .

[0020] The preparation technology of above-mentioned mulberry beer comprises the following specific steps:

[0021] Step 1. Weigh the raw materials, crush corn and wheat germ through an 80-mesh sieve to obtain a mixed powder, add water to the mixed powder, stir at a speed of 300rpm, heat to 60°C, heat for 1.5 hours, and centrifuge twice After obtaining the filtrate;

[0022] Step 2, add hops to the filtrate, stir at 200 rpm for 5 minutes, then heat at 80°C for 15 minutes, and when it is naturally cooled to 30°C, add mulberry extract and honeysuckle extract, stir and keep warm for 5 minutes to obtain a mixture;

[0023] Step 3, adding yeast to the mixture, fermenting for 8 hours under a vacuum of -0.02MPa, adjusting the pH to 6.5, and then pasteurizing to obtain mulber...

Embodiment 2

[0025] A mulberry beer comprising the following raw materials by mass percentage: 10% mulberry extract, 14.0% corn, 48% wheat germ, 0.4% honeysuckle extract, 5% glucose, 0.6% hops, 1.4% yeast, and 20% water , 0.06% of Dendrobium officinale extract.

[0026] The preparation technology of above-mentioned mulberry beer comprises the following specific steps:

[0027] Step 1. Weigh the raw materials, crush corn and wheat germ through a 100-mesh sieve to obtain a mixed powder, add water to the mixed powder, stir at a speed of 450rpm, heat to 70°C, heat for 2.0 hours, and centrifuge 3 times After obtaining the filtrate;

[0028] Step 2, add hops to the filtrate, stir at 400 rpm for 7 minutes, then heat at 85°C for 18 minutes, and when it is naturally cooled to 35°C, add mulberry extract and honeysuckle extract, stir and keep warm for 8 minutes to obtain a mixture;

[0029] Step 3, adding yeast to the mixture, fermenting for 9 hours under a vacuum of -0.02MPa, adjusting the pH to 7...

Embodiment 3

[0031] A mulberry beer comprising the following raw materials by mass percentage: 10% mulberry extract, 14.0% corn, 48% wheat germ, 0.4% honeysuckle extract, 5% glucose, 0.6% hops, 1.4% yeast, and 20% water , 0.06% of Dendrobium officinale extract.

[0032] The preparation technology of above-mentioned mulberry beer comprises the following specific steps:

[0033] Step 1. Weigh the raw materials, crush corn and wheat germ through a 120-mesh sieve to obtain a mixed powder, add water to the mixed powder, stir at a speed of 600rpm, heat to 75°C, heat for 2.5 hours, and centrifuge 4 times After obtaining the filtrate;

[0034] Step 2, add hops to the filtrate, stir at 500 rpm for 10 minutes, then heat at 90°C for 20 minutes, and when it is naturally cooled to 40°C, add mulberry extract and honeysuckle extract, stir and keep warm for 10 minutes to obtain a mixture;

[0035] Step 3: adding yeast to the mixture, fermenting for 10 h under a vacuum of -0.02 MPa, adjusting the pH to 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com