Steel reinforcement arrangement structure of steel structure-concrete slag combined bridge

A technology for concrete slabs and steel structures, applied in bridges, bridge materials, bridge construction, etc., can solve the problems of material waste, inability to resist lateral bending moments in local areas, etc., and achieve the effect of simple construction and improved concrete bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below with reference to the accompanying drawings.

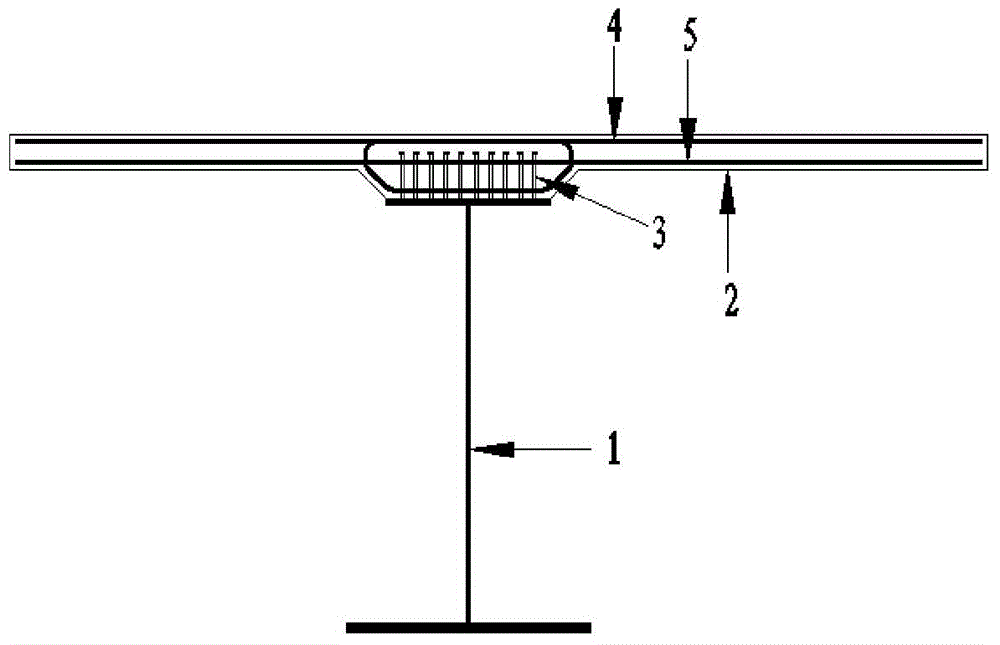

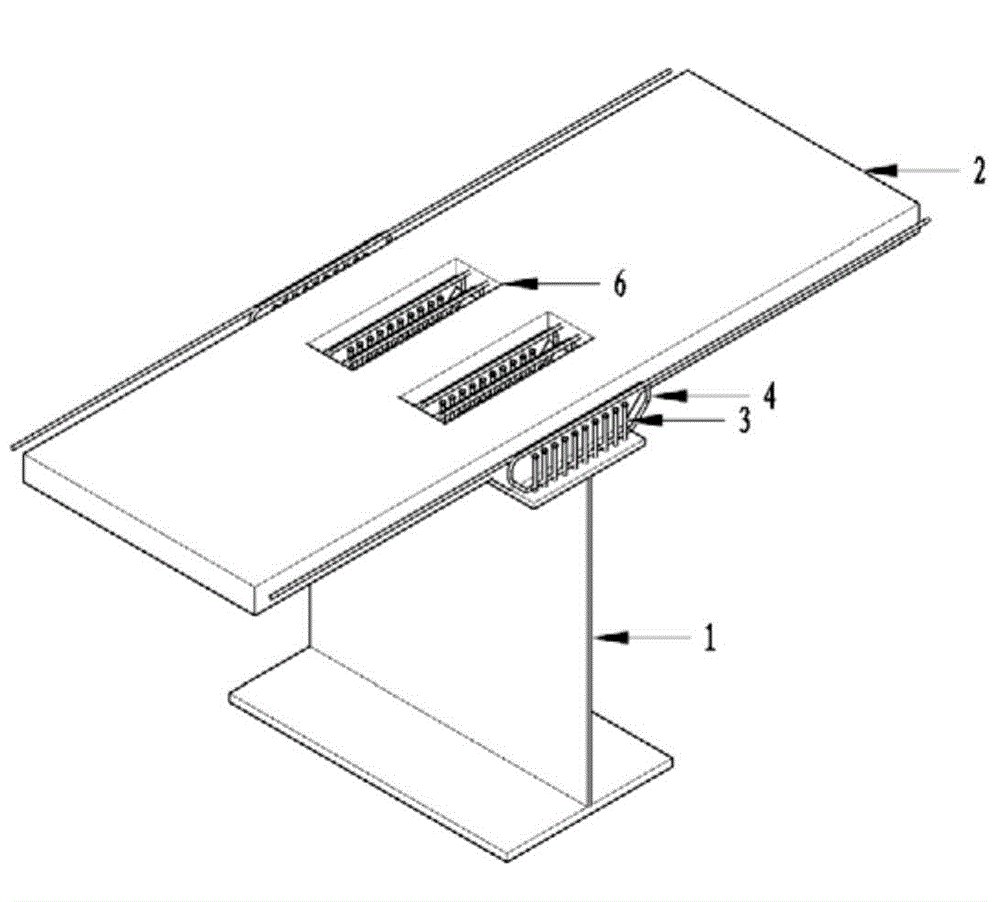

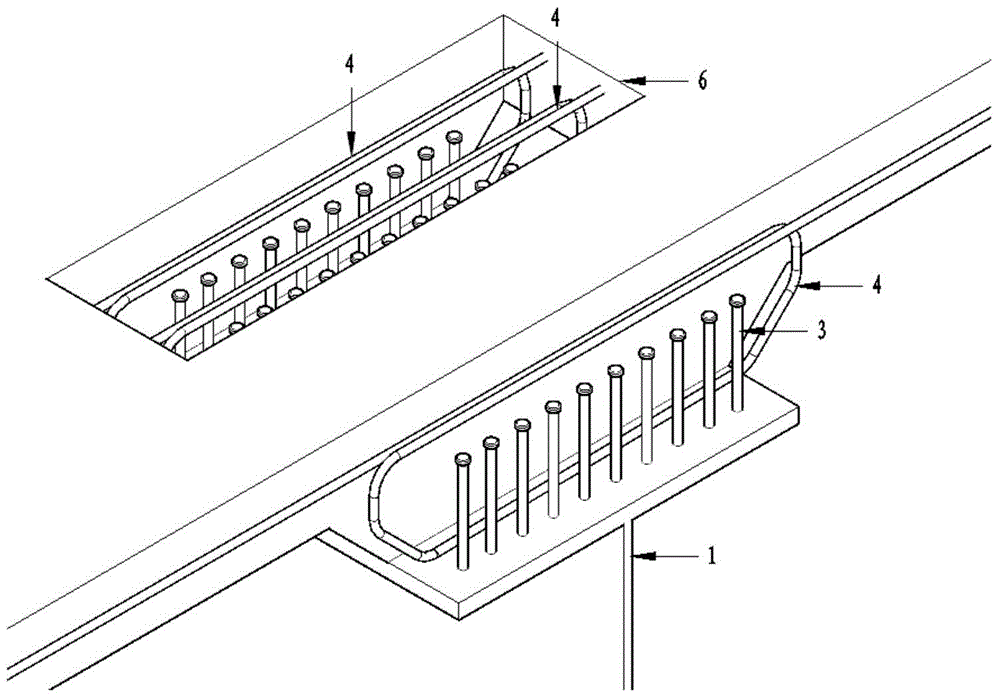

[0014] refer to figure 1 , figure 2 , image 3 , Figure 4 , the transverse main reinforcement is bent at the joint notch to form a hoop 4, and extends over the top surface of the steel structure 1, the hoop 4 and the transverse main reinforcement 5 on it form an integral tendon structure, and the overall tendon structure and the shear stud in the joint notch 6 3 Stagger the layout to form a steel reinforcement structure, and the steel reinforcement structure is simultaneously used as a roof beam, combined notch stirrups, and a bottom beam beam. According to the specific construction requirements, the steel reinforcement structure adopts different spacing arrangements.

[0015] When adopting the construction of the present invention, the integral reinforcement structure formed by the hoop 4 and the transverse main reinforcement 5 thereon is manufactured in a facto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com