Energy-saving and environment-friendly transformed heating system for safe non-pressure operation of boilers

An energy-saving and environmental-friendly heating system technology, applied in hot water central heating systems, heating systems, household heating, etc., can solve problems such as damage to pressure-bearing components, boiler safety hazards, and unreasonable boiler structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

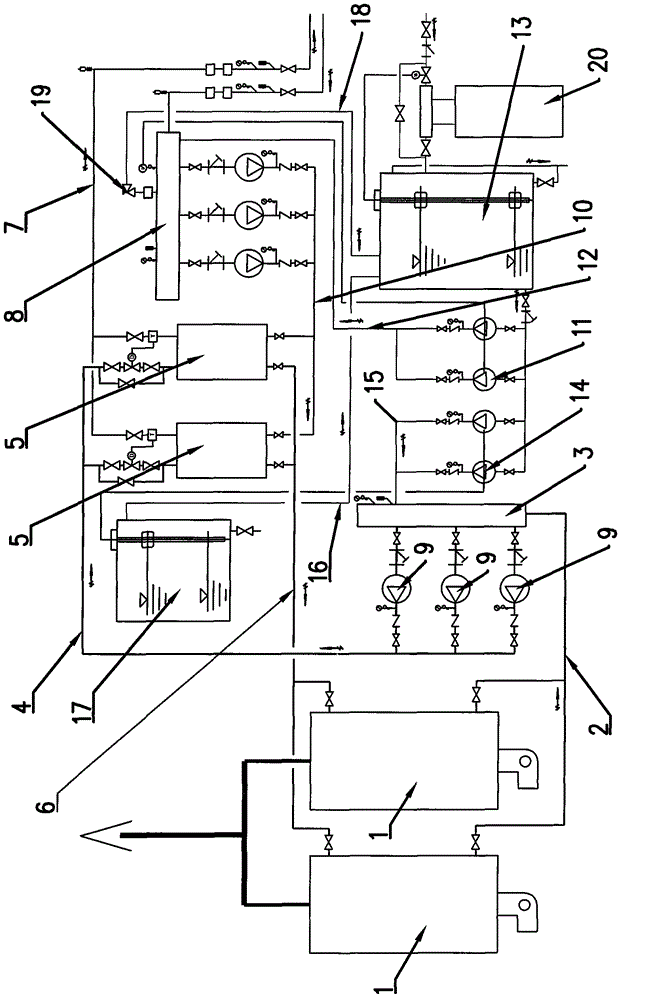

[0016] see figure 1 , the boiler safety pressureless operation energy saving and environmental protection transformation heating system of the present invention comprises a plurality of boilers 1, the water supply port of each boiler 1 is connected with the water inlet of the inner circulation water supply pipe 2 respectively, the water outlet of the inner circulation water supply pipe 2 is connected with the water inlet of the inner circulation water supply pipe 2 The water inlet of the internal circulation heat storage tank 3 is connected, and a plurality of heat storage tubes made of stainless steel are evenly distributed in the internal circulation heat storage tank 3 along the vertical direction. The top wall is fixedly connected, and the bottom end of each heat storage tube (not shown in the figure) is fixedly connected with the bottom of the internal circulation heat storage tank 3 respectively. The cross section of each heat storage tube is circular, oval or rectangular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com