Experimental device for the durability of frp bars under the coupling effect of tensile stress and environment

A tensile stress and environment technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems that the coupling between stress and environment is difficult to achieve, and the durability of FRP bars and the high tensile strength of FRP bars are less considered. Achieve the effect of avoiding loading frame corrosion, overcoming large volume problems, and uniform stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

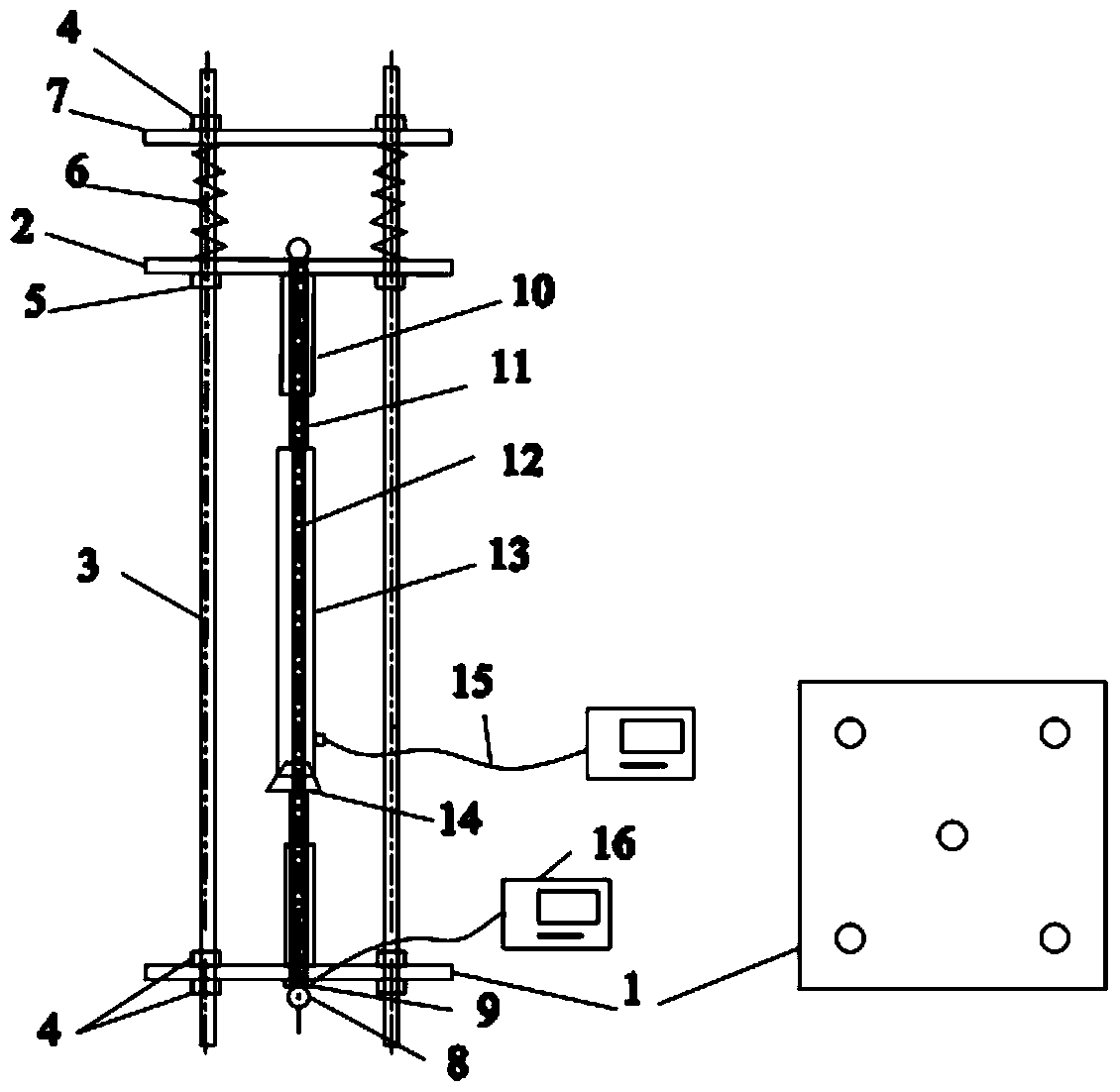

[0036] Experimental device for the durability of FRP bars under the coupling effect of tensile stress and environment, see figure 1 , comprising a pull-down plate 1, a positioning plate 7, a pull-up plate 2 located between the pull-down plate 1 and the positioning plate 7, passing through the pull-up plate 2 and utilizing a positioning nut 4 to be arranged between the pull-down plate 1 and the positioning plate 7 4 pull rods 3, universal ball hinge 8 with threaded rod, sample loading sleeve 10, glass tube 13, temperature controller 15; 4 pull rods 3 are evenly distributed; the bottom of the upper pull plate 2 is provided with a booster nut 5. There is a spring 6 between the upper pull plate 2 and the positioning plate 7; the middle parts of the pull-down plate 1 and the upper pull plate 2 are respectively provided with holes, and a pair of universal ball hinges 8 with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com