A polarization conversion device

A technology of polarization conversion and polarization conversion, which is applied in the field of high NA polarization illumination for lithography to achieve the effect of increasing mechanical strength, ensuring stability and ensuring alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better illustrate the purpose and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

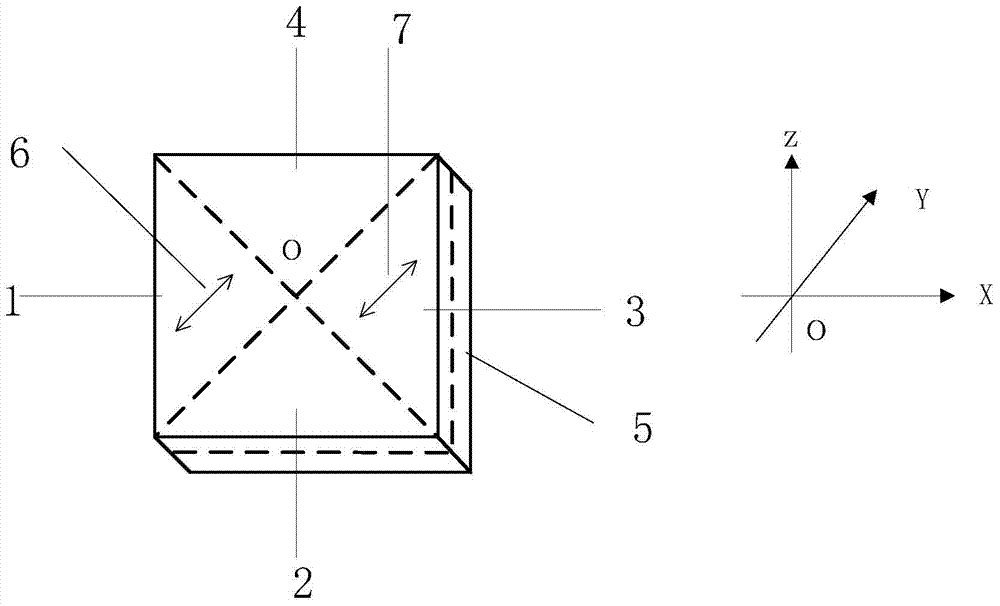

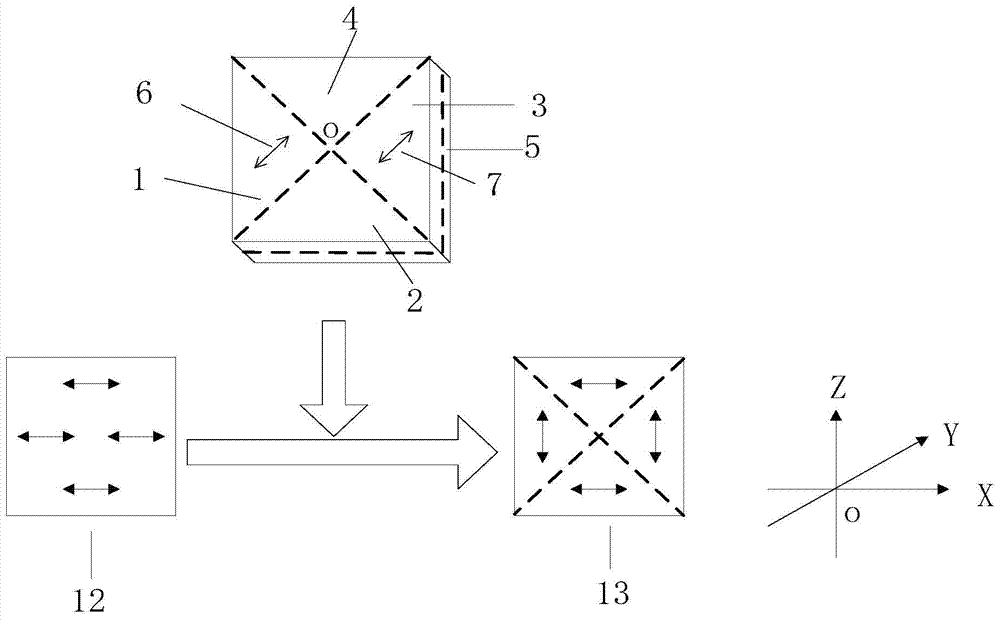

[0022] figure 1 It is a structural schematic diagram of a polarization conversion device, including a half-wave plate 1 , a fused silica substrate 2 , a half-wave plate 3 , a fused silica substrate 4 and a fused silica substrate 5 . Half wave plate 1, fused silica substrate 2, half wave plate 3, and fused silica substrate 4 have central angles of 90 degrees, and half wave plate 1 and half wave plate 3 Arranged alternately with fused silica substrates 2 and fused silica substrates 4, such as figure 1 As shown, the half-wave plate 1 and the half-wave plate 3 have the same thickness as the fused silica substrate 2 and the fused silica substrate 4 and are isosceles right triangles, and the depth optical glue is on the fused silica substrate 5 . The half-wave plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com