Radiating control method for high-voltage power distribution cabinets

A technology of high-voltage power distribution cabinet and control method, which is applied in the direction of temperature control using electric method, cooling/ventilation of substation/switchgear, electrical components, etc. , to achieve the effect of improving cooling efficiency, not easy to generate, and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

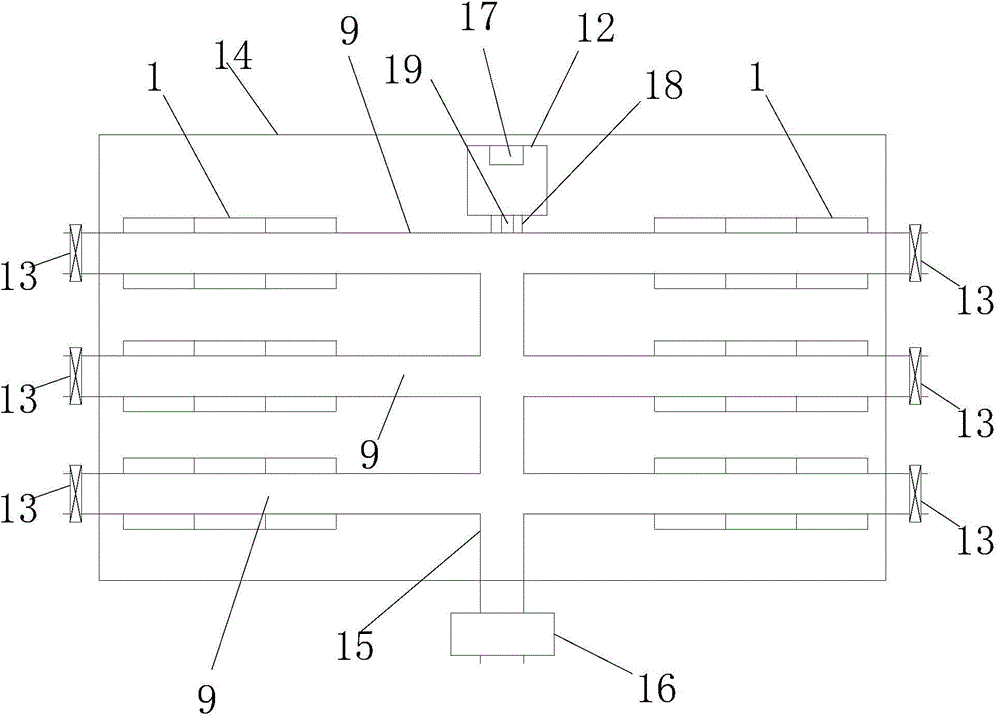

[0034] like figure 1 , 2, 3, and 4, the heat dissipation control method of the high-voltage power distribution cabinet described in this embodiment places the power distribution cabinet 1 in the electrical room 14, and the power distribution cabinet 1 is divided into multiple rows, and each row of power distribution cabinets 1 are distributed in a straight line, and the lower part of each power distribution cabinet 1 is provided with an air inlet 4, and the installation board 3 for installing electrical components is generally provided in the power distribution cabinet 1, and the characteristic is that: above each row of power distribution cabinets 1 Both ends are provided with an air duct 9 outside the electrical room 14, and the air outlet 11 on the top of the power distribution cabinet 1 communicates with the air duct 9 through the heat dissipation pipe 12; With technology, the simplest damper can be an electric flapper valve. The damper 13 is usually in an open state, and...

Embodiment 2

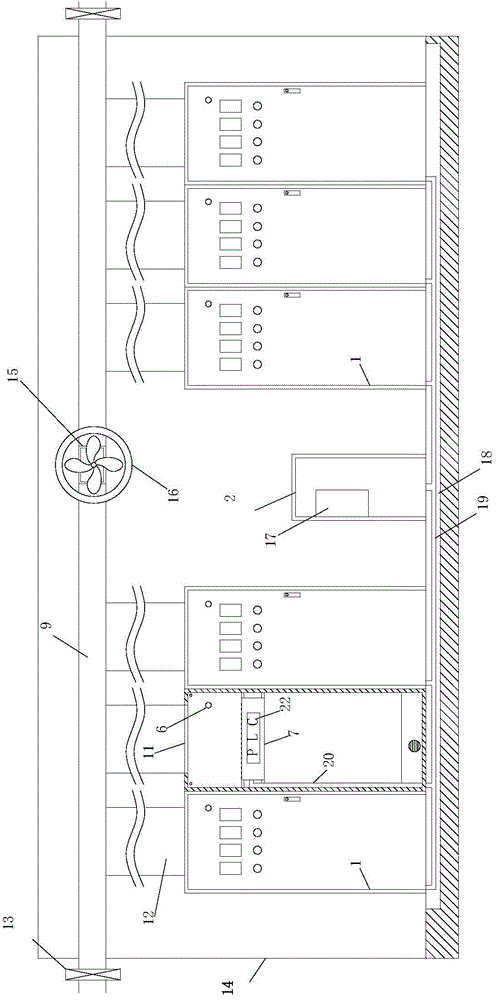

[0042] like Figure 5 , 6 , 7, and 8, the heat dissipation control method of the high-voltage power distribution cabinet described in this embodiment is different from the method described in Embodiment 1 in that:

[0043] Each power distribution cabinet 1 is also provided with a cold air cover 8, which is covered with air outlet holes 10, and the cold air cover 8 communicates with the cold air pipe 19 through the second pipeline 21, and the second pipeline 21 is provided with a cold air valve 23; After the cold air valve 23 is opened, the cold air in the air cooler 2 is released through the cold air cover 8 to cool down the power distribution cabinet 1 .

[0044] A temperature sensor 6 is provided in each power distribution cabinet 1, a fan 5 is provided on the air inlet 4 at the bottom of each power distribution cabinet 1, and a master controller 24 is provided in the air-conditioning cabinet 2, and each power distribution cabinet The signals of the temperature sensor 6 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com