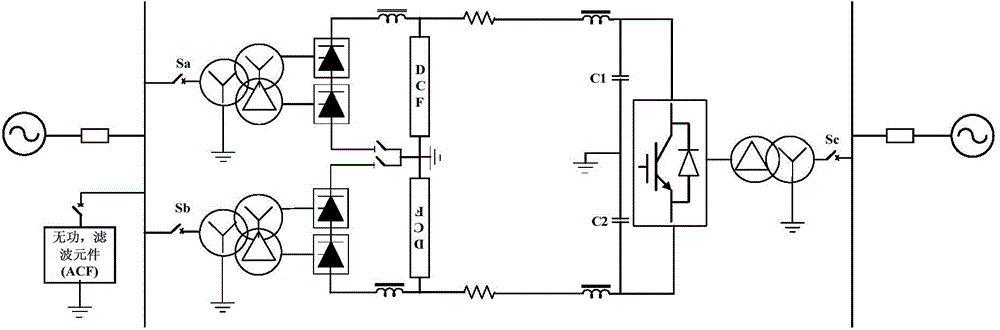

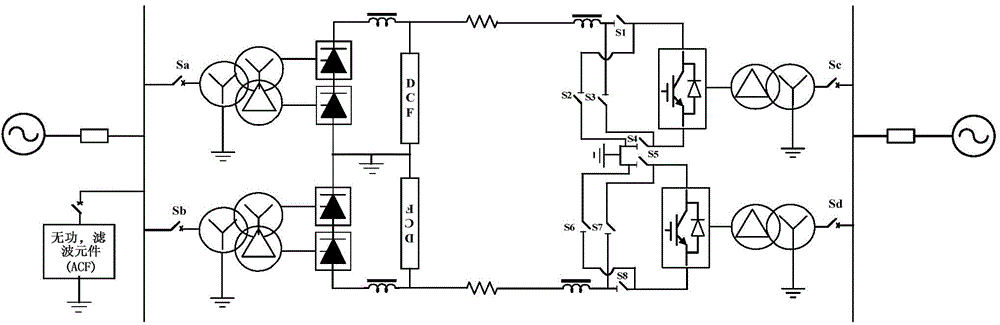

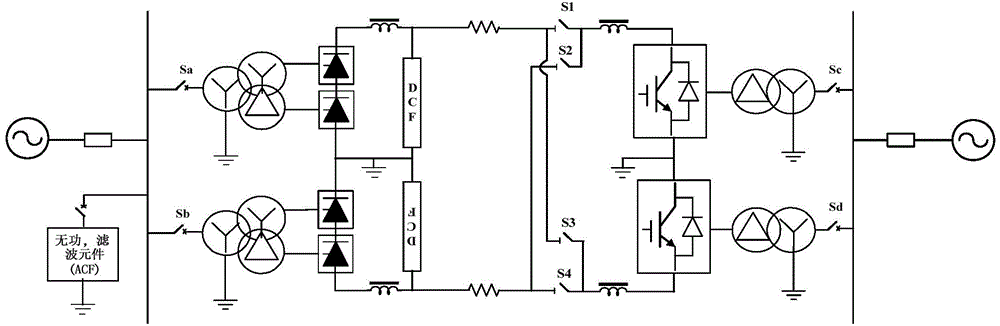

Hybrid direct-current transmission topology structure and control method

A hybrid DC transmission and topology technology, applied in the direction of power transmission and AC network, can solve the problems of bipolar DC transmission system increasing system investment cost, only changing the direction of DC current, not changing, only changing voltage polarity, etc. , to achieve the effect of low loss, easy flow capacity and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: the whole power flow reversal process is as shown Figure 7 as shown,

[0039] Specifically include the following steps:

[0040] (1) Obtain the automatic power flow reversal start signal;

[0041] (2) Reduce the DC power of the positive and negative poles at a certain rate until the DC current of the two poles drops to the minimum current;

[0042] (3) After the two-pole DC current drops to the minimum current, issue a step-down command, and at the same time modify the per-unit value of the voltage reference value to k1, and the value range of k1 is 0 to 1;

[0043] (4) When the DC voltage of the two poles drops to the voltage reference value, the DC current of one pole is reduced to zero and the operation is stopped;

[0044] (5) Wait for 0 to 60 minutes after one pole of DC is out of operation, and then reduce the other pole's DC current to zero;

[0045] (6) After both poles of DC are out of service, disconnect the AC circuit breakers Sc and Sd on ...

Embodiment 2

[0049] Example 2: When the negative DC is out of operation, the relevant equipment in the converter station where the voltage source converter is located is overhauled, and the power flow reversal process is as follows when only the positive DC is running:

[0050] (1) Obtain the automatic power flow reversal start signal;

[0051] (2) Reduce the positive DC power at a certain rate until the positive DC current drops to the minimum current;

[0052] (3) After the positive DC current drops to the minimum current, issue a step-down command, and at the same time modify the per-unit value of the voltage reference value to k3, and the value range of k3 is 0 to 1;

[0053] (4) When the positive DC voltage drops to the voltage reference value, stop the positive DC;

[0054] (5) After the positive DC is out of service, disconnect the AC circuit breaker Sc on the primary side of the transformer connected to the voltage source converter, and disconnect the switches on the positive and ...

Embodiment 3

[0057] Embodiment 3: The power transmission from the AC grid connected to the thyristor converter to the AC grid connected to the thyristor converter needs to be changed from the AC grid connected to the thyristor converter to the voltage source converter. The AC power grid transmits power, and the entire power flow reversal process specifically includes the following steps:

[0058] (1) Obtain the automatic power flow reversal start signal;

[0059] (2) Reduce the DC power of the positive and negative poles at a certain rate until the DC current of the two poles drops to the minimum current;

[0060] (3) After the direct current of two poles drops to the minimum current, the direct current of one pole is reduced to zero to stop operation;

[0061] (4) Wait for 0 to 60 minutes after one pole of DC is out of operation, and then reduce the DC current of the other pole to zero for outage;

[0062] (5) After both poles of DC are out of service, disconnect the AC circuit breakers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com