Switch reluctance machine with stator separated from rotor

A switched reluctance motor, segmented technology, applied in the direction of synchronous machines, electromechanical devices, electrical components, etc., can solve the problems that the cost of the controller cannot be reduced, cannot be made into a two-phase motor, and the cost of clicking is increased, so as to reduce wind (Oil) loss, simple and convenient winding, and the effect of reducing the overall density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

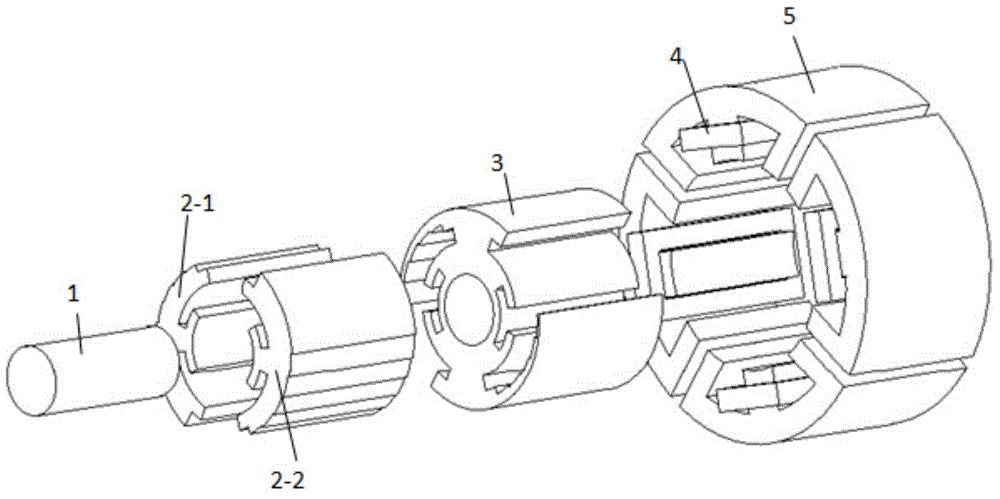

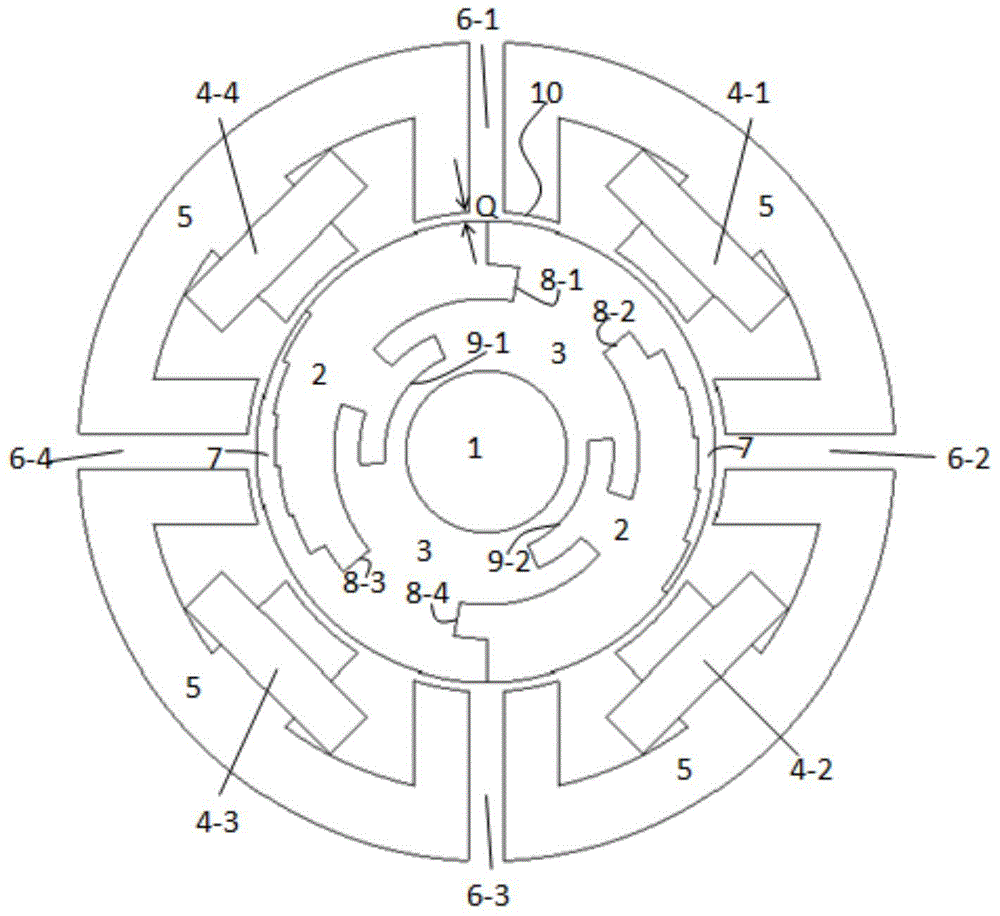

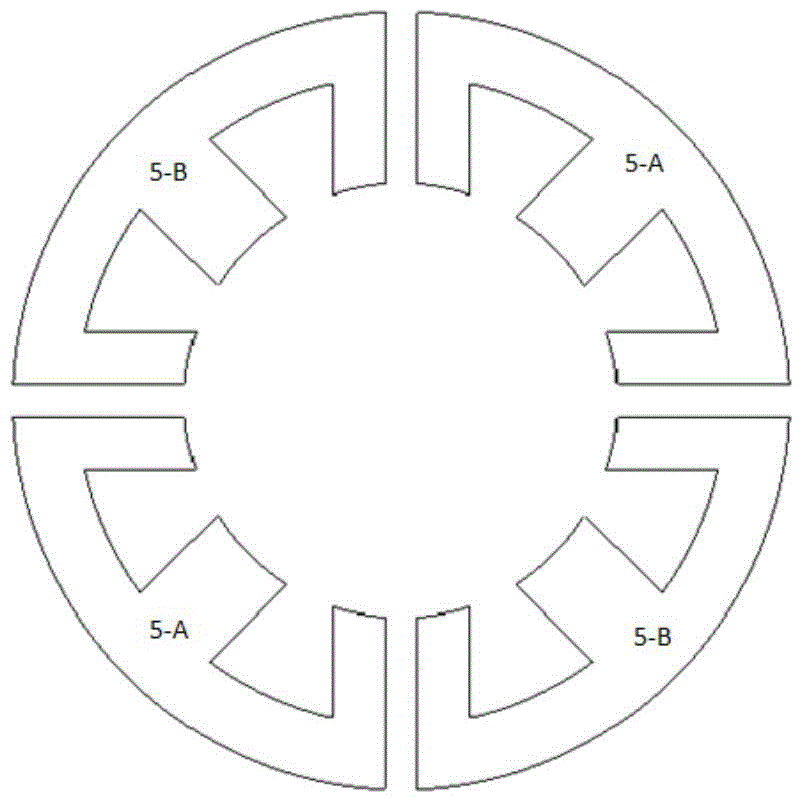

[0040] The stator-rotor segmented switched reluctance motor is a multi-phase motor. The number of poles of the motor stator (the number of E-shaped iron cores in the view of the end of the motor) is an even number, and the optimal number of phases is 2. The present invention intends to use 4 stators A two-phase switched reluctance motor with an E-shaped iron core structure and a rotor with two segmented magnetic core structures, that is, a 4-2 structure, will be described as an example. Such as figure 1 , 2 Shown is a two-phase stator E-type structure, stator and rotor segmented switched reluctance motor. The motor stator consists of an E-shaped iron core 5, coil windings 4-1 to 4-4 and magnetic isolation materials (located at the positions indicated by 6-1 to 6-4); figure 1 , 2 Shown is the structural diagram of a 4-pole stator-rotor segmented swit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com