Novel micro-porous ceramic irrigation emitter for infiltrating irrigation technology and preparation method thereof

A technology of microporous ceramics and sprinklers, which is applied in the direction of botanical equipment and methods, watering devices, applications, etc., can solve the problems that hinder the development of seepage irrigation technology, low irrigation uniformity, and high cost, and achieve a significant filtering effect and reduce The effect of production cost and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

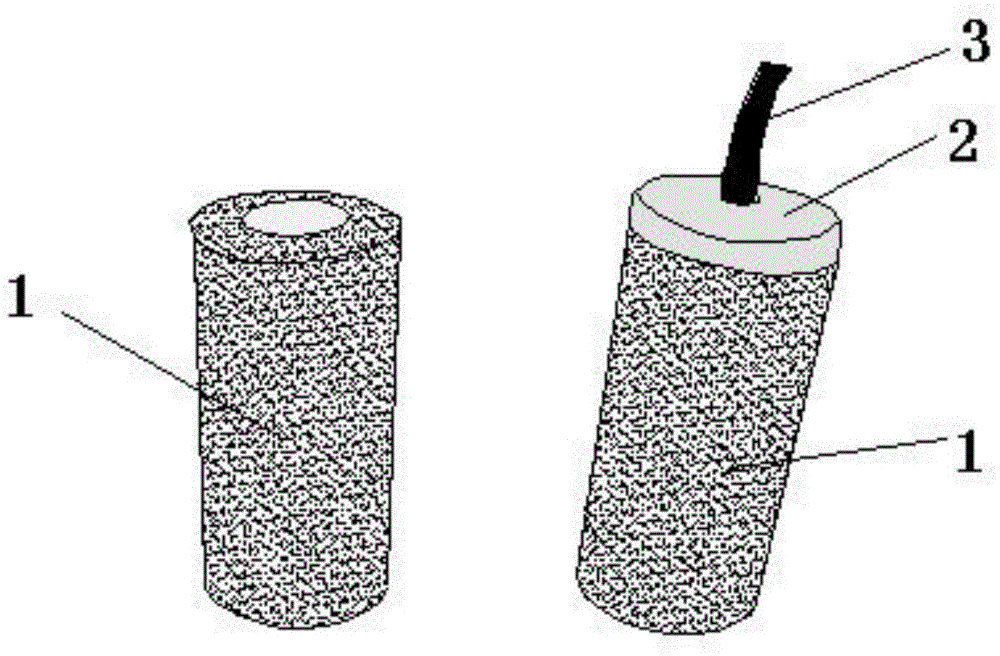

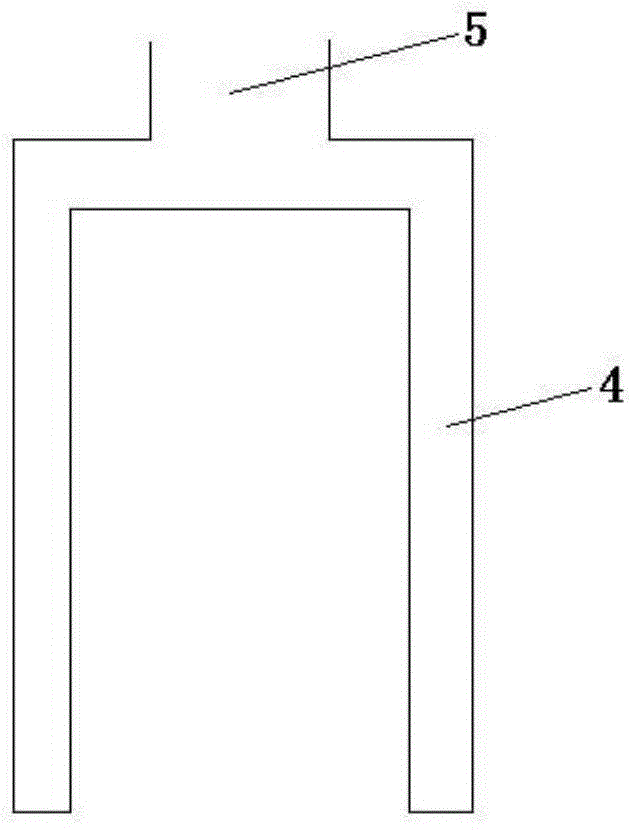

[0033] like Figure 1~2 As shown, a microporous ceramic emitter of a new type of seepage irrigation technology is characterized in that: it comprises: a barrel-shaped emitter 1, a top cover 2 is arranged on the top of the barrel-shaped emitter 1, and the top cover 2 is connected with the It communicates with the micropipe 3 that pours water into the barrel emitter 1 , and the micropipe 3 also communicates with the capillary; the barrel emitter 1 is made of a mold 4 .

[0034] The shape of the mold 4 is an inverted barrel, and the top of the inverted barrel is provided with an upwardly protruding opening 5 .

[0035] The material of the top cover 2 is hard nylon.

[0036] The barrel-shaped emitter 1 has a height of 70 mm, an outer diameter of 30 mm, an internal water storage chamber diameter of 15 mm, and an internal water storage chamber depth of 65 mm.

[0037] A method for preparing a microporous ceramic emitter with a novel seepage irrigation technology, characterized in ...

Embodiment 2

[0059] like Figure 1~2 As shown, a microporous ceramic emitter with new seepage irrigation technology is characterized in that: the height of the barrel emitter 1 is 90mm, the outer diameter is 50mm, the diameter of the inner water storage chamber is 25mm, and the depth of the inner water storage chamber is 80mm.

[0060] A method for preparing a microporous ceramic emitter with new seepage irrigation technology, characterized in that the proportion of calcium sulfate is 20%.

[0061] All the other contents are the same as in Example 1.

Embodiment 3

[0063] like Figure 1~2 As shown, a microporous ceramic emitter with new seepage irrigation technology is characterized in that: the height of the barrel emitter 1 is 80mm, the outer diameter is 40mm, the diameter of the inner water storage chamber is 25mm, and the depth of the inner water storage chamber is 65mm.

[0064] A method for preparing a microporous ceramic emitter with new seepage irrigation technology, characterized in that the proportion of calcium sulfate is 10%.

[0065] All the other contents are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com