Electric inclined tube settling tank

A technology of inclined tube sedimentation tank and sedimentation tank, which is applied in the direction of sedimentation tank, feeding/discharging device of sedimentation tank, etc., can solve the problems of silent structure, oblique tube packing, difficult to move downward, etc., and achieves the degree of automation High, easy to use, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with embodiment the present invention is further described.

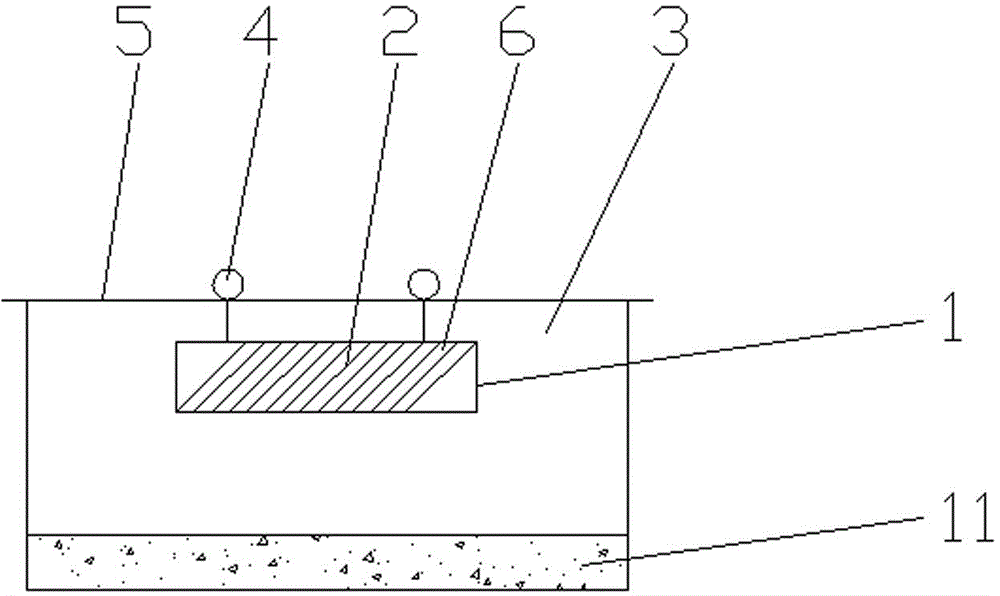

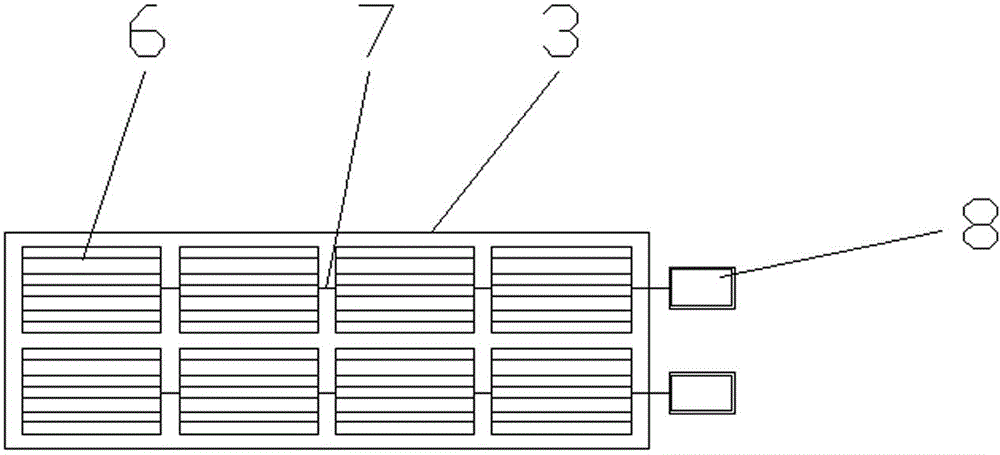

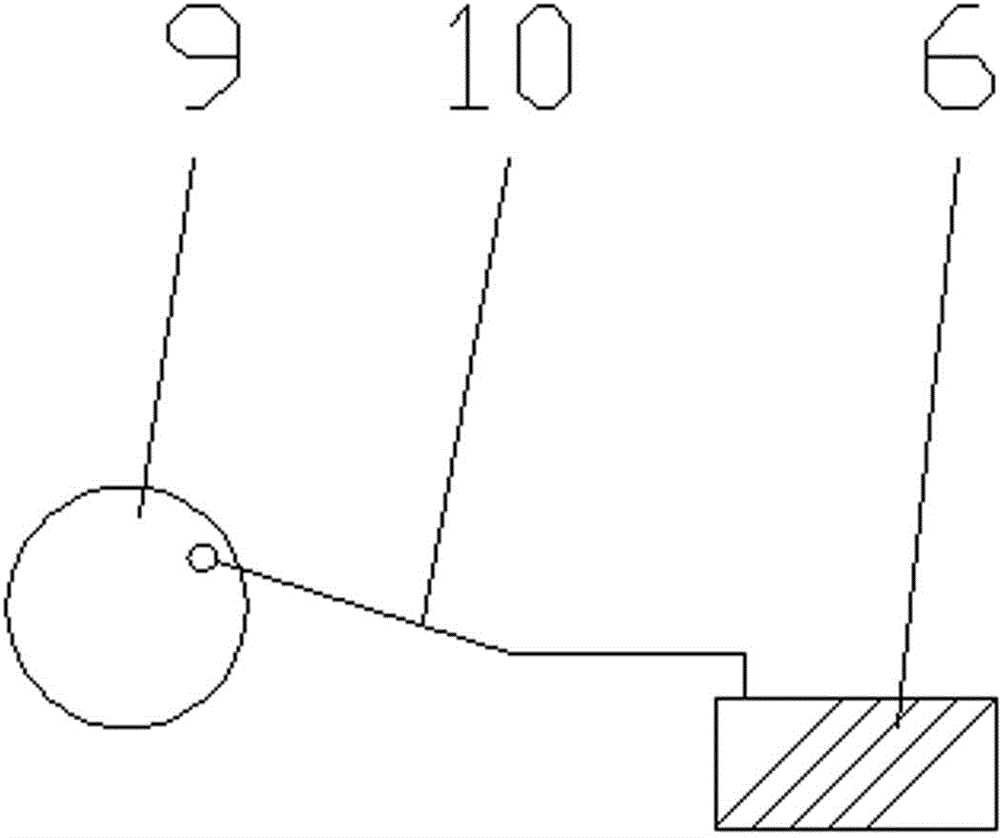

[0020] see Figure 1 ~ Figure 3 , an electric inclined tube 2 sedimentation tank 3, including a sedimentation tank 3, several steel frames 1 are installed in the sedimentation tank 3, and several inclined tubes 2 are placed in the frame 1, thereby forming an inclined tube frame 6 , a track 5 is erected on the top of the sedimentation tank 3, and the inclined tube frame 6 is fixedly connected with the pulley 4 located on the track 4. The inclined tube frame 6 located in the sedimentation tank 3 is fixedly connected by a steel piece 7 and is jointly vibrated by a Driven by the vibrator 8, the inclined tube frame 6 and the vibrator 8 are connected by a reciprocating rod 10. The vibrator 8 is composed of a motor and an eccentric wheel 9. The motor is connected to the dynamic eccentric wheel 9, and the eccentric wheel 9 is reciprocated through a connecting rod. The moving rod 10 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com