High efficiency air filtering and purifying material

A technology of air filtration and purification materials, applied in the direction of filtration separation, chemical instruments and methods, separation methods, etc., can solve the problems of increased power consumption of fans, increased equipment noise, and increased energy efficiency ratio of the system, so as to reduce structural costs and Energy consumption, low airflow resistance and high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the air filter in the present invention is not particularly limited, and the air filter purification material of the present invention can be assembled in the air filter by the method of the prior art.

[0041] The above-mentioned features mentioned in the present invention, or the features mentioned in the embodiments can be combined arbitrarily. All the features disclosed in the specification of this case can be used in combination with any combination, and each feature disclosed in the specification can be replaced by any alternative feature that provides the same, equivalent or similar purpose. Therefore, unless otherwise specified, the disclosed features are only general examples of equivalent or similar features.

[0042] The benefits of the present invention are:

[0043] (1) The present invention provides a novel air filter purification material.

[0044] (2) The air filter and purification material of the present invention can effect...

Embodiment 1

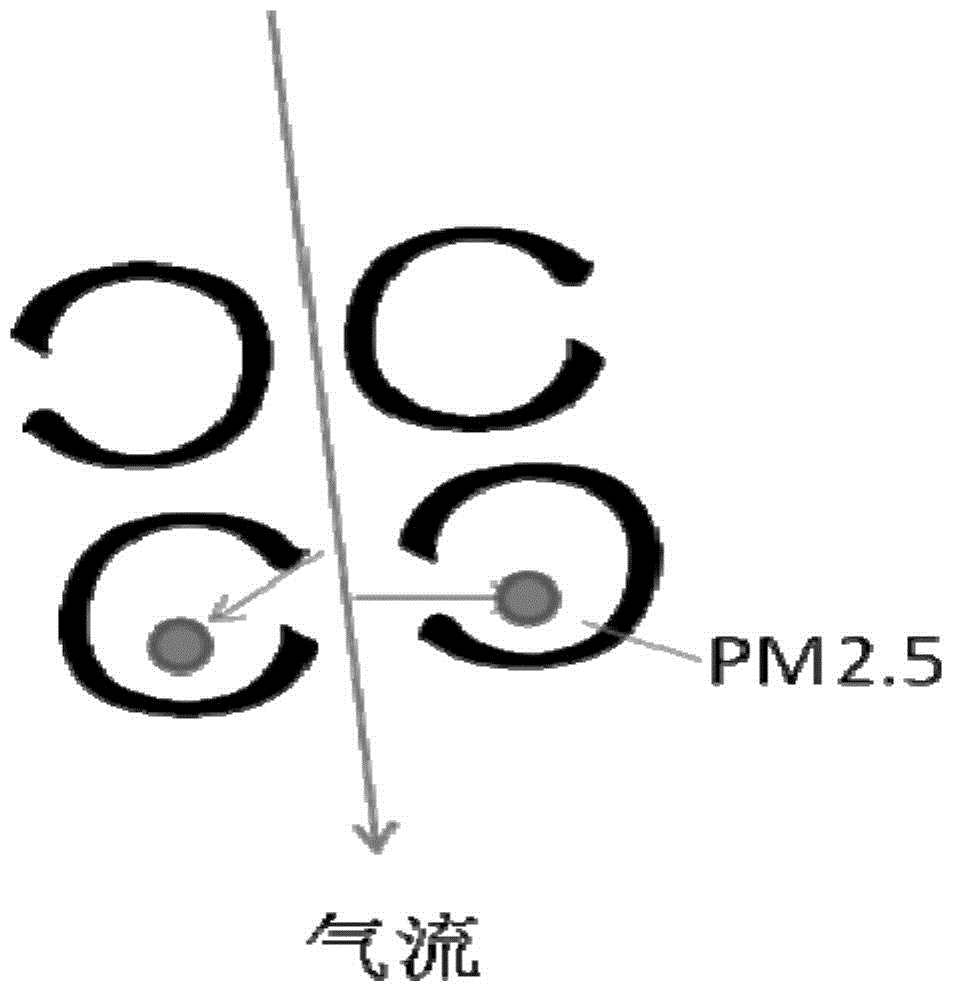

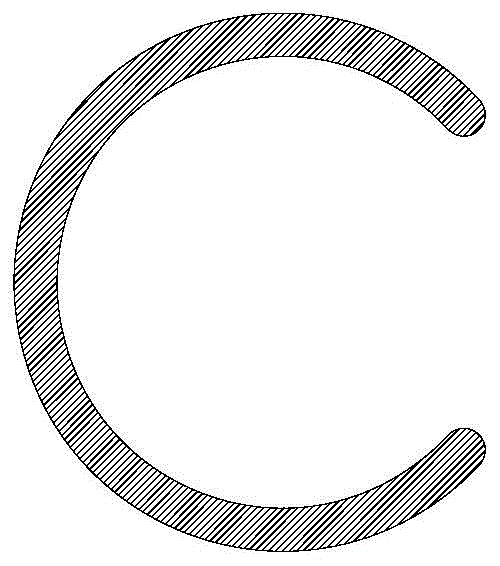

[0051] Polylactic acid is used as raw material to make C-shaped cross-section fibers. The cross-section is as follows: figure 1 As shown, the fineness is 5dtex. The length of a single fiber is about 2 mm, and the non-woven fabric material for air filtration is made into the special-shaped cross-section fiber through a hydroentanglement method.

[0052] The air filter is made of the above materials, and the filtration efficiency of PM0.3~PM10 respirable suspended particles is 99.8%, and the filtration efficiency of atmospheric bacteria is 100%. 3 Under the condition of air volume per hour, the initial resistance of airflow is 20Pa.

[0053] Under the same conditions, test the current commercial high-efficiency air filter, the filtration efficiency reaches 99.9%, and the initial airflow resistance is 150Pa.

Embodiment 2

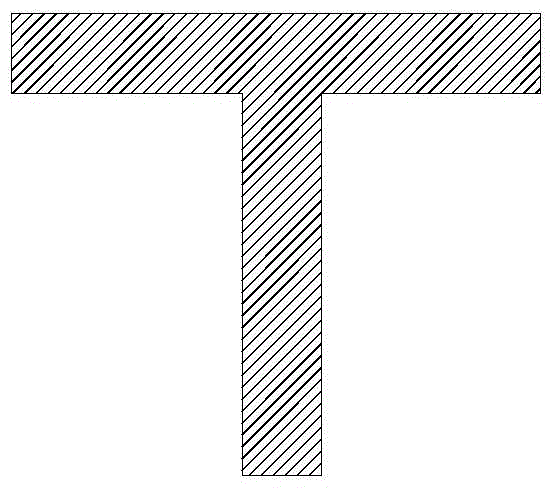

[0055] Using polypropylene as raw material, T-shaped and H-shaped cross-section fibers are made respectively, the fineness is 0.5dtex, and the cross-section is as follows figure 2 and image 3 shown. The length of a single fiber is 5 mm, and two kinds of special-shaped cross-section fibers are made into a non-woven fabric material for air filtration by a melt blown method.

[0056] The air filter is made of the above materials, and the filtration efficiency of PM0.3~PM10 respirable suspended particles is 99.9%, and the filtration efficiency of atmospheric bacteria is 100%. 3 Under the condition of air volume per hour, the initial resistance of airflow is 40Pa.

[0057] Under the same conditions, test the current commercial high-efficiency air filter, the filtration efficiency reaches 99.9%, and the initial airflow resistance is 120Pa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com