Filter Element

A filter element, flat filter technology, applied in the direction of membrane filter, dispersed particle filtration, separation method, etc., can solve the problems of poor separation effect, small dust storage capacity, high flow resistance, etc., to achieve small pressure loss, dust storage The effect of enhanced capacity and compact construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

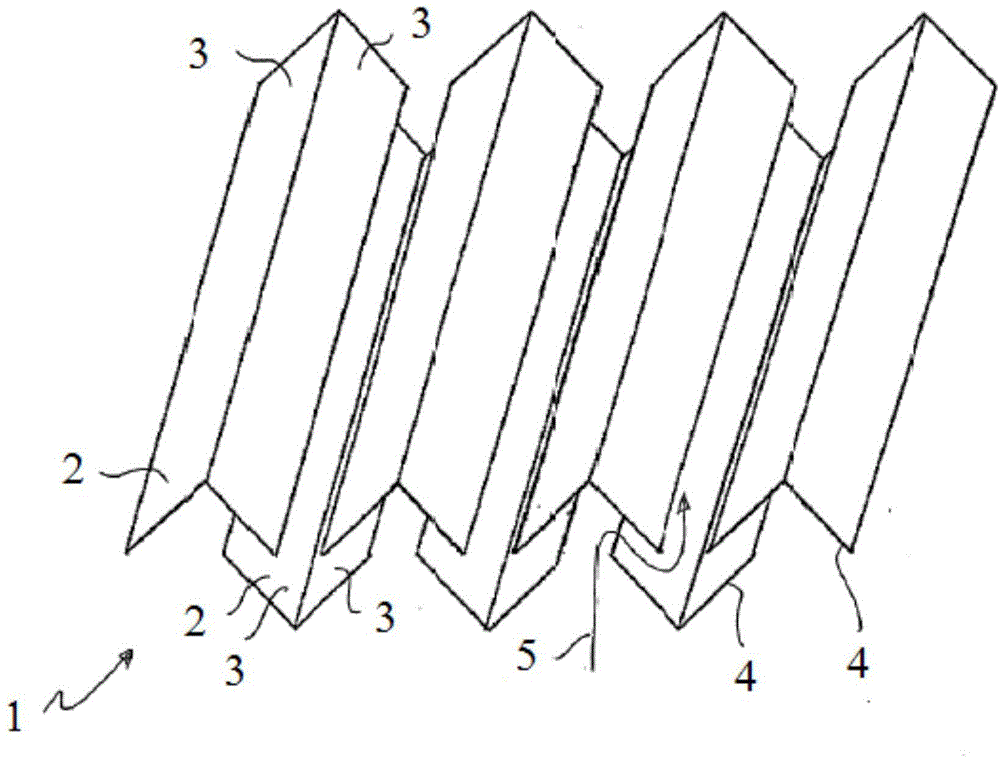

[0019] figure 1 Shown is a filter element 1 designed as an inertial separator, ie with a device 2 that separates particles by deflection of a flow medium. Device 2 has a nonwoven.

[0020] The device 2 is designed as a folding wall 3 which is produced from or has a nonwoven.

[0021] The filter element 1 has a plurality of V-shaped or saddle-shaped folded wall pairs 4 , wherein each two folded wall pairs 4 are spaced apart from each other, arranged opposite each other and offset relative to each other, so that at least one flow channel 5 is formed between these folded wall pairs . The flow channels 5 are schematically indicated by arrows.

[0022] The folded wall pairs 4 each span two planes, wherein the planes are spaced from one another, and the folded wall pairs 4 are likewise spaced apart from one another in the planes.

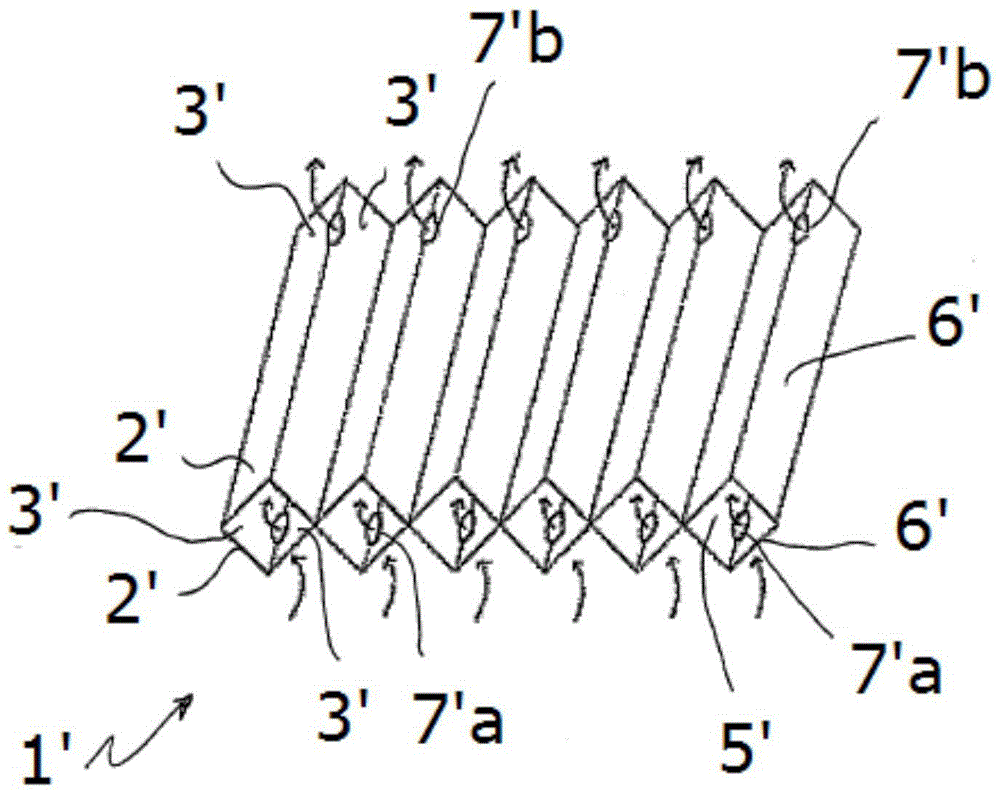

[0023] figure 2 Shown is a filter element 1 ′ designed as an inertial separator, ie with a device 2 ′, which separates particles by deflection of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com