Novel single-pole pipe and plate fully automatic welding machine

A single-column, fully automatic technology, applied in the direction of welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems that the equipment is difficult to use normally, the dimensional accuracy is not high, and the assembly quality problems, etc., to achieve simple structure and ensure welding The effect of quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

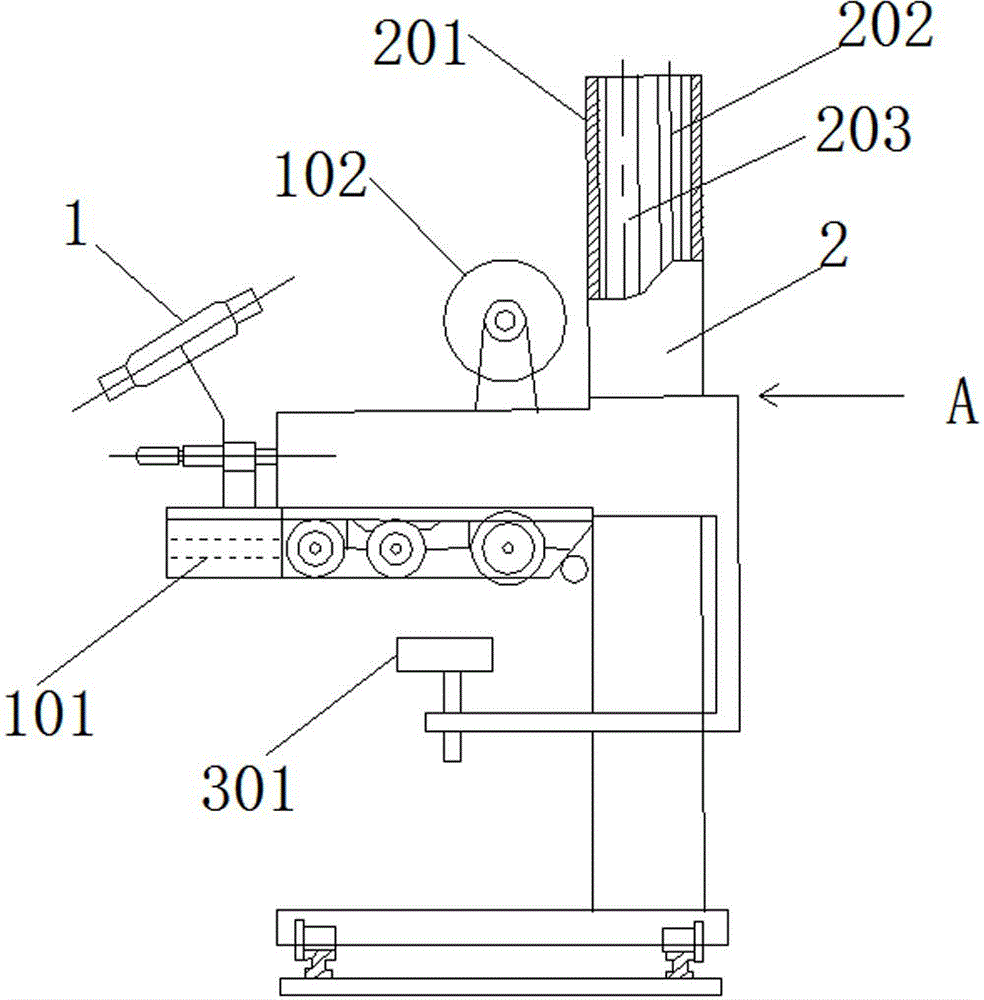

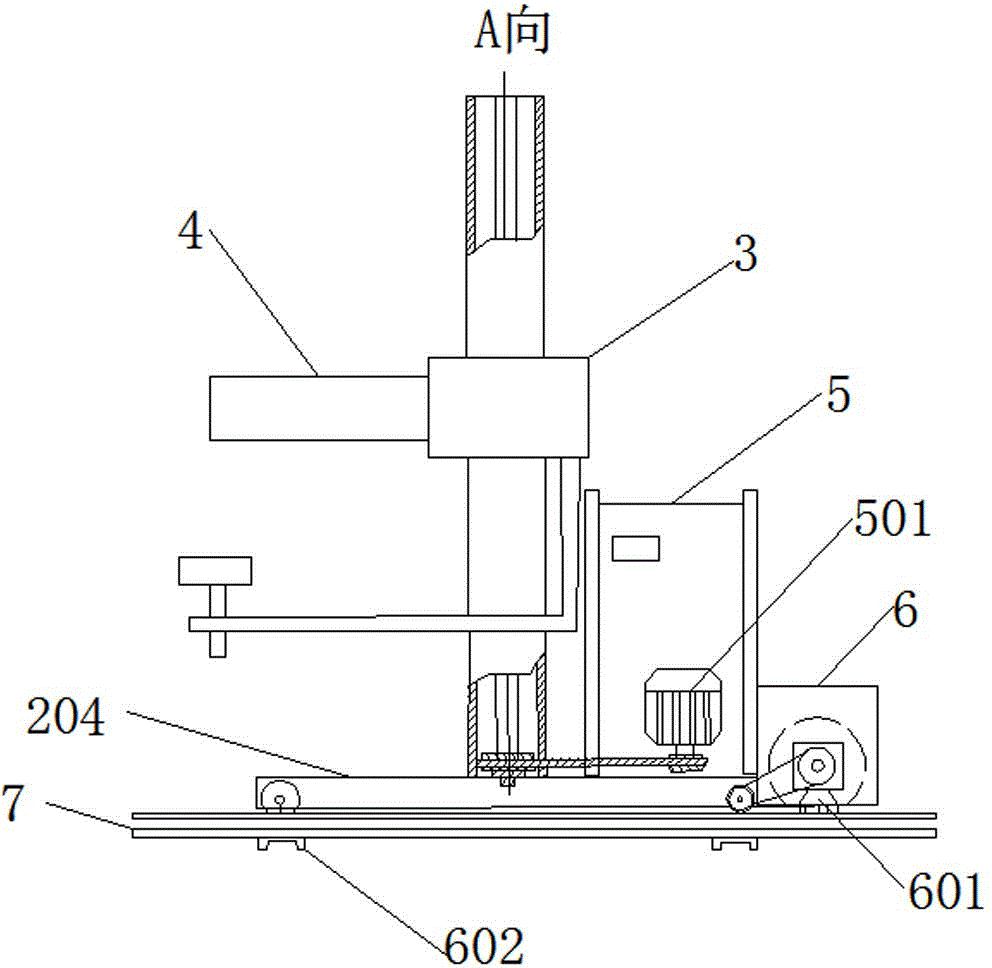

[0014] The present invention is a novel single-column tube-plate automatic welding machine, which mainly includes a welding head 1, an electrical control box 4, a welding power supply 5 and a walking device 6, and the welding head 1 and the electrical control box 4 are provided with On the working platform 3, the rear of the welding head 1 and the top of the working platform 3 are provided with a large wire reel 102, the electric control box 4 is provided with a button plate 101, and the lower end of the working platform 3 is provided with a There is a connecting rod, and the connecting rod is movably connected to the chair 301 .

[0015] The working platform 3 is arranged on the periphery of the support tube 2, and the inside of the support tube 2 is longitudinally provided with a first guide rail 201, a column 202, and a screw mandrel 203; the platform can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com