Acid-alkaline combined technology for pre-desiliconizing and extracting aluminium oxide from coal solid wastes

A solid waste, acid-base combination technology, applied in the removal of solid waste, alumina/aluminum hydroxide, silicon oxide, etc., can solve the problems of large sintering amount, difficult separation of aluminum and silicon, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

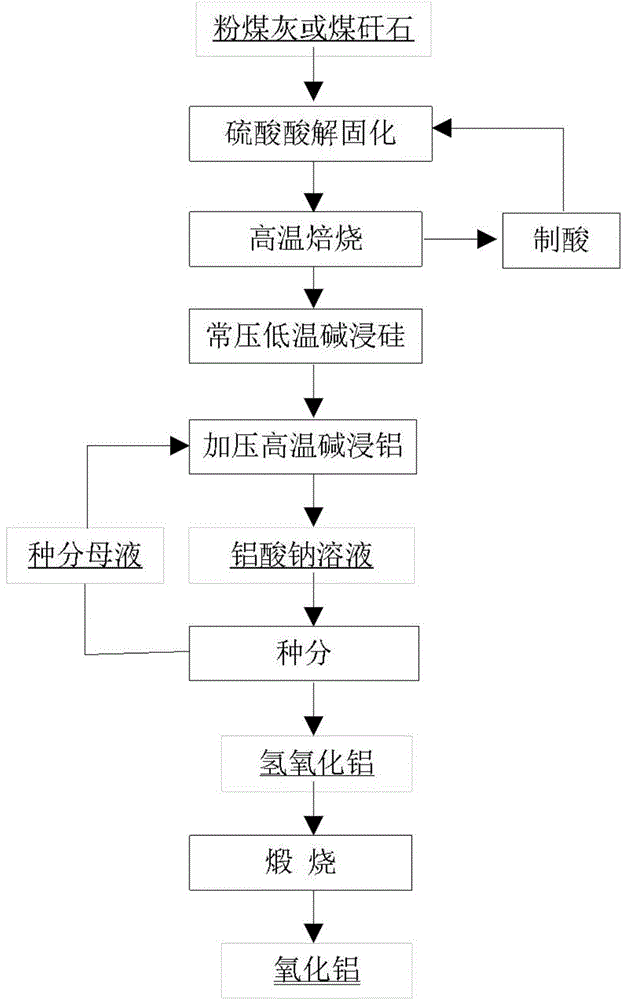

Method used

Image

Examples

Embodiment 1

[0027] The fly ash containing 48% of alumina and 42% of silicon dioxide is mixed with sulfuric acid, and the amount of sulfuric acid added is Al in the fly ash 2 o 3 3.5 times the number of moles, and the mass concentration of sulfuric acid used is 90%. After mixing evenly, acidolysis and solidification are carried out at 250°C. The reaction time is 2h. Na for calcination 2 O concentration 100g / L sodium hydroxide solution leaching, leaching solid-liquid mass and volume ratio 1:10, leaching temperature 85 ℃, leaching time 60min, filter and obtain silicon-containing leaching solution and high-alumina slag, the leaching rate of silicon is 75%; The obtained high alumina slag was treated with Na 2 Sodium hydroxide solution with an O concentration of 200g / L leaches aluminum, the leaching solid-liquid mass-to-volume ratio is 1:5, and the ingredient molecular ratio is α k 1.4, the amount of lime added is 5% of the mass of high aluminum slag, the leaching temperature is 250°C, the l...

Embodiment 2

[0029] The fly ash containing 48% of alumina and 42% of silicon dioxide is mixed with sulfuric acid, and the amount of sulfuric acid added is Al in the fly ash 2 o3 4.5 times the number of moles, and the mass concentration of sulfuric acid used is 95%. After mixing evenly, acidolysis and solidification are carried out at 300°C for 2 hours. Na for calcination 2 O concentration 50g / L sodium hydroxide solution leaching, leaching solid-liquid mass and volume ratio 1:5, leaching temperature 85 ℃, leaching time 60min, filter and obtain silicon-containing leaching solution and high-alumina slag, the leaching rate of silicon is 60%; The obtained high aluminum slag is Na 2 Sodium hydroxide solution with an O concentration of 200g / L leaches aluminum, the leaching solid-liquid mass-to-volume ratio is 1:5, and the ingredient molecular ratio is α k 1.4, the amount of lime added is 10% of the mass of high aluminum slag, the leaching temperature is 250°C, the leaching time is 30min, and th...

Embodiment 3

[0031] Grind coal gangue containing 38% of alumina and 48% of silicon dioxide to 0.1mm and mix it with sulfuric acid. The amount of sulfuric acid added is the amount of Al in the fly ash 2 o 3 3.5 times the number of moles, and the mass concentration of sulfuric acid used is 95%. After mixing evenly, acidolysis and solidification are carried out at 300°C for 2 hours. Na for calcination 2 O concentration 100g / L sodium hydroxide solution leaching, leaching solid-liquid mass and volume ratio 1:10, leaching temperature 85 ℃, leaching time 60min, filter and obtain silicon-containing leaching solution and high-alumina slag, the leaching rate of silicon is 68%; The obtained high aluminum slag is Na 2 Sodium hydroxide solution with an O concentration of 200g / L leaches aluminum, the leaching solid-liquid mass-to-volume ratio is 1:5, and the ingredient molecular ratio is α k 1.4, the leaching temperature is 250°C, the leaching time is 30min, and the aluminum leaching rate is 82%. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com