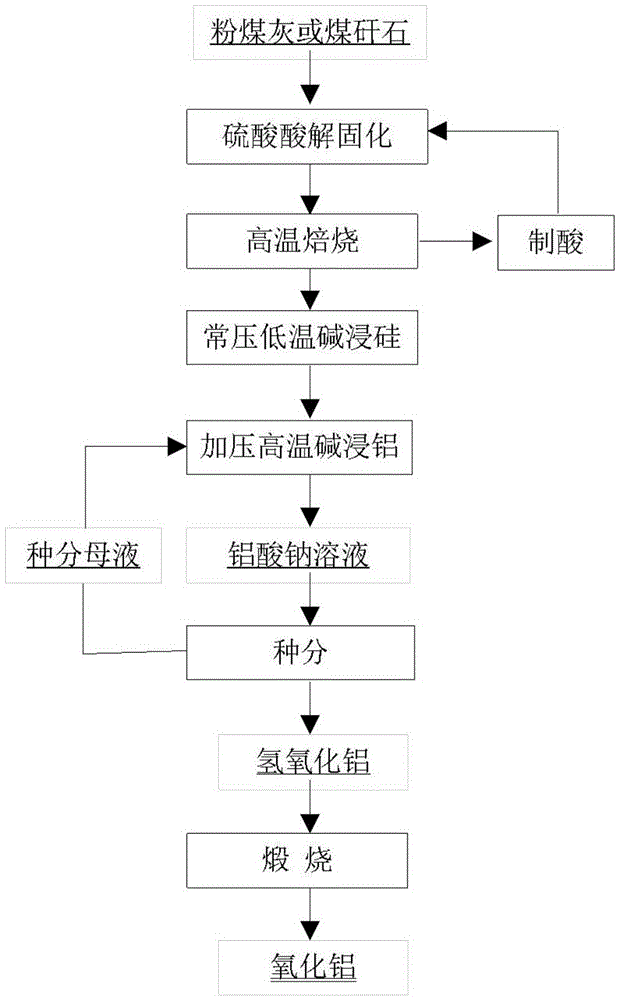

An acid-alkaline combined process for extracting alumina from coal series solid waste by pre-desilication

A combination of solid waste and acid-base technology, which is applied in the removal of solid waste, alumina/hydroxide, silicon oxide, etc., can solve the problems of large sintering amount, difficult separation of aluminum and silicon, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The fly ash containing 48% of alumina and 42% of silicon dioxide is mixed with sulfuric acid, and the amount of sulfuric acid added is Al in the fly ash 2 o 3 3.5 times the number of moles, and the mass concentration of sulfuric acid used is 90%. After mixing evenly, acidolysis and solidification are carried out at 250°C. The reaction time is 2h. Na for calcination 2 O concentration 100g / L sodium hydroxide solution leaching, leaching solid-liquid mass and volume ratio 1:10, leaching temperature 85 ℃, leaching time 60min, filter and obtain silicon-containing leaching solution and high-alumina slag, the leaching rate of silicon is 75%; The obtained high alumina slag was treated with Na 2 Sodium hydroxide solution with an O concentration of 200g / L leaches aluminum, the leaching solid-liquid mass-to-volume ratio is 1:5, and the ingredient molecular ratio is α k 1.4, the amount of lime added is 5% of the mass of high aluminum slag, the leaching temperature is 250°C, the l...

Embodiment 2

[0029] The fly ash containing 48% of alumina and 42% of silicon dioxide is mixed with sulfuric acid, and the amount of sulfuric acid added is Al in the fly ash 2 o 34.5 times the number of moles, and the mass concentration of sulfuric acid used is 95%. After mixing evenly, acidolysis and solidification are carried out at 300°C for 2 hours. Na for calcination 2 O concentration 50g / L sodium hydroxide solution leaching, leaching solid-liquid mass and volume ratio 1:5, leaching temperature 85 ℃, leaching time 60min, filter and obtain silicon-containing leaching solution and high-alumina slag, the leaching rate of silicon is 60%; The obtained high alumina slag was treated with Na 2 Sodium hydroxide solution with an O concentration of 200g / L leaches aluminum, the leaching solid-liquid mass-to-volume ratio is 1:5, and the ingredient molecular ratio is α k 1.4, the amount of lime added is 10% of the mass of high aluminum slag, the leaching temperature is 250°C, the leaching time is...

Embodiment 3

[0031] Grind coal gangue containing 38% of alumina and 48% of silicon dioxide to 0.1mm and mix it with sulfuric acid. The amount of sulfuric acid added is the amount of Al in the fly ash 2 o 3 3.5 times the number of moles, and the mass concentration of sulfuric acid used is 95%. After mixing evenly, acidolysis and solidification are carried out at 300°C for 2 hours. Na for calcination 2 O concentration 100g / L sodium hydroxide solution leaching, leaching solid-liquid mass and volume ratio 1:10, leaching temperature 85 ℃, leaching time 60min, filter and obtain silicon-containing leaching solution and high-alumina slag, the leaching rate of silicon is 68%; The obtained high alumina slag was treated with Na 2 Sodium hydroxide solution with an O concentration of 200g / L leaches aluminum, the leaching solid-liquid mass-to-volume ratio is 1:5, and the ingredient molecular ratio is α k 1.4, the leaching temperature is 250°C, the leaching time is 30min, and the aluminum leaching rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com