Macrocrystalline fused magnesite smelting furnace

A technology of electric fused magnesia and smelting furnace, which is applied in the field of electric fused magnesia smelting furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

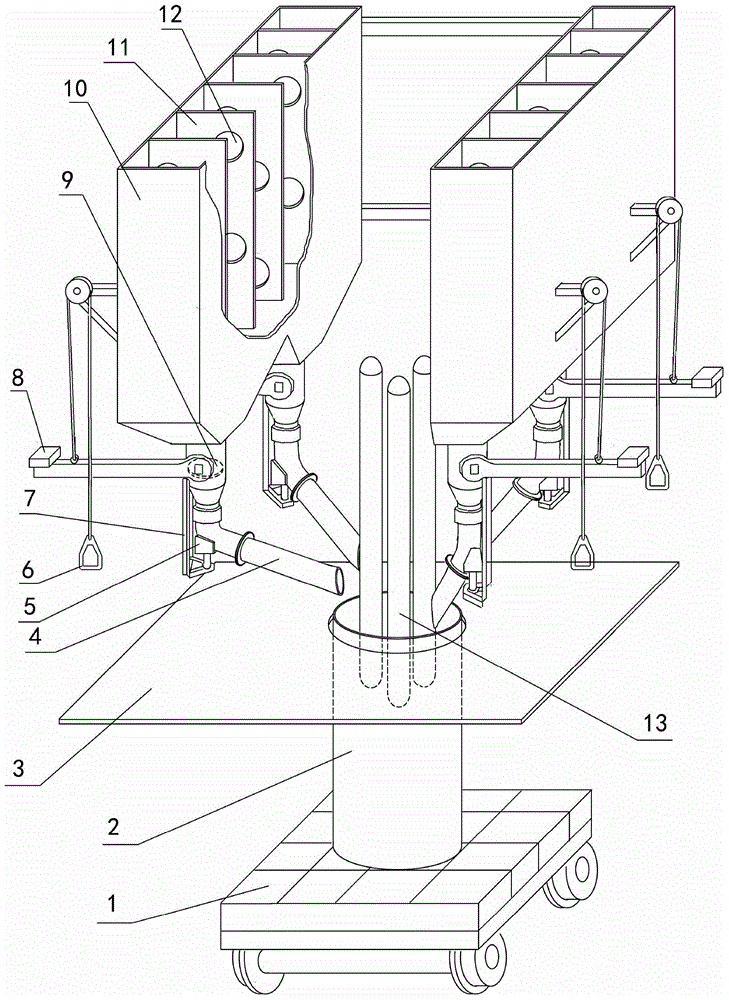

[0007] Below in conjunction with accompanying drawing, the present invention will be further described

[0008] The furnace body 2 is located on the track platform 1 . An operating platform 3 is arranged on the upper part of the furnace body. Electrodes 13 are housed in the furnace body. There are feed bins 10 on both sides above the furnace body, and the feed bins are cuboids. A heat conduction plate 11 is provided in the feed bin, and a material leakage hole 12 is provided on the heat conduction plate. There is a casing at the bottom of the feed bin, and a cloth pipe 4 is set in the casing, and a support frame 7 is arranged at the rear of the cloth pipe, and the support frame is welded on the sleeve pipe. A support 5 is arranged on the support frame, and a seat shaft is provided on the support. There is a flashboard 9 in the sleeve pipe, and there is a brake handle on the flashboard movable shaft. There is a counterweight 8 at the rear of the brake handle, and a handle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com