Device for lighting charcoal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

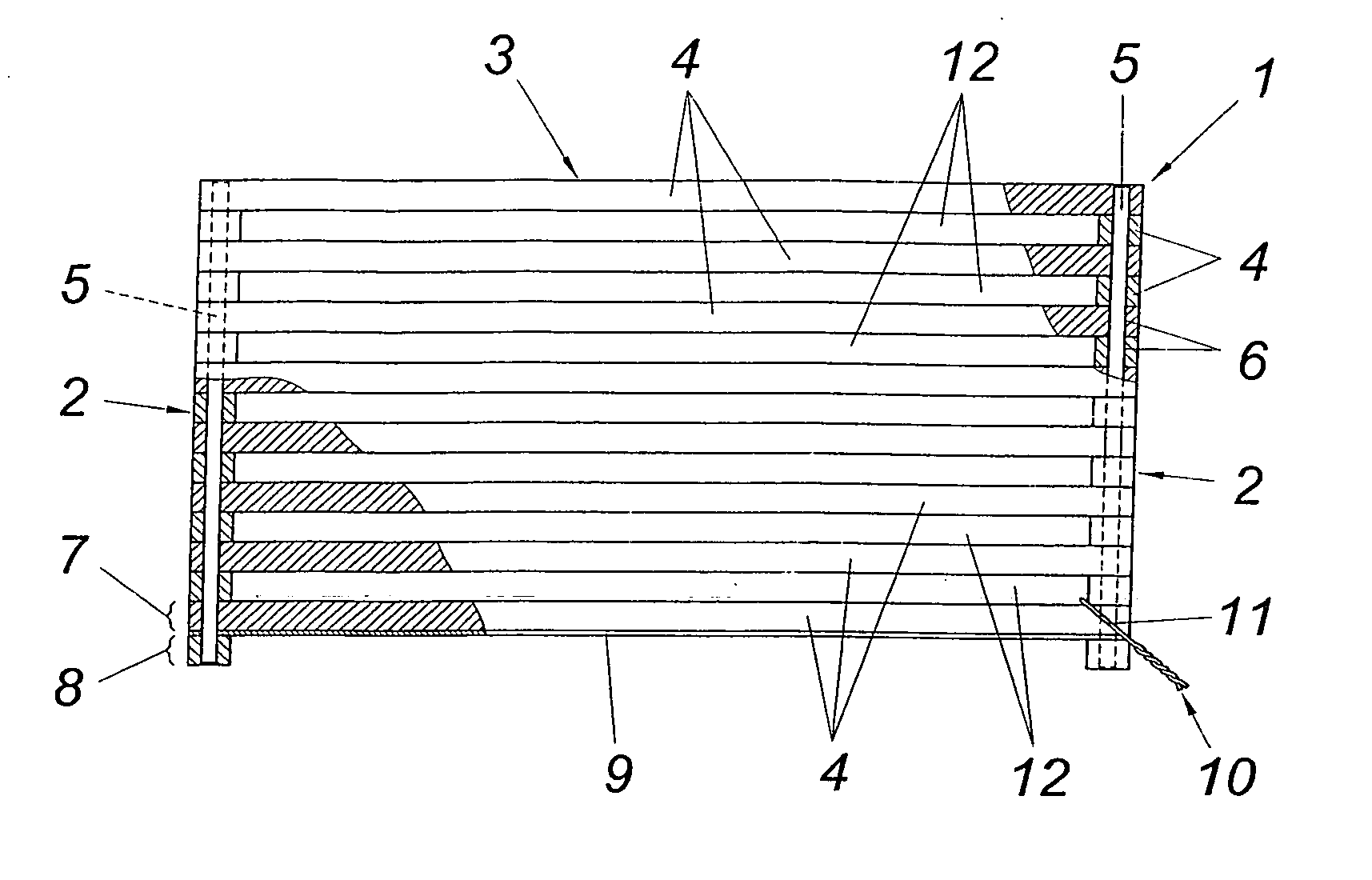

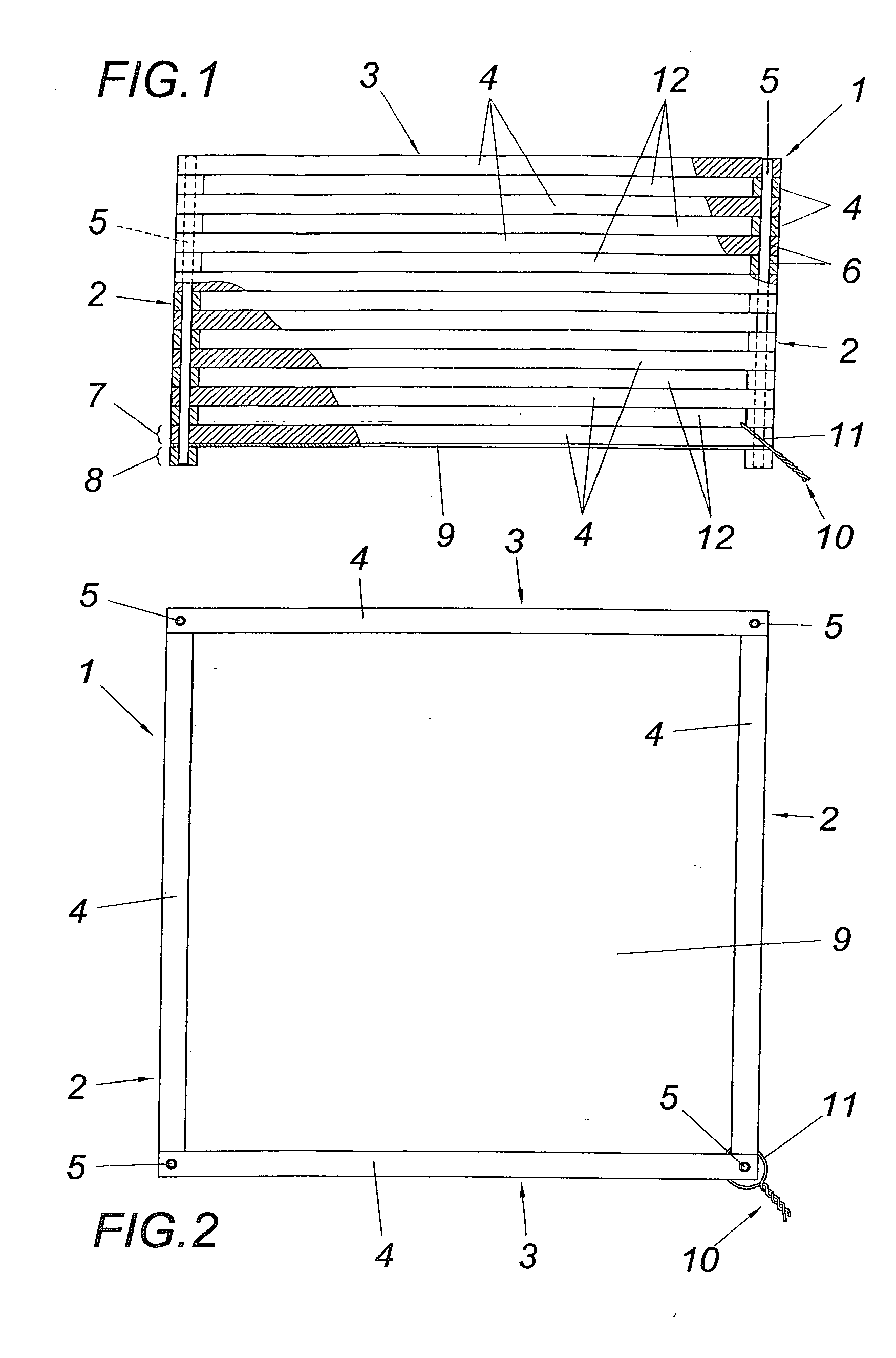

[0014] The illustrated apparatus consists according to the shown embodiment of a cage with a circumferential wall 1 which is square in its layout and comprises cage walls 2 and 3 which are opposite of each other in pairs. Said cage walls 2 and 3 are each composed of rods 4 made of sawn wooden laths which are spaced and arranged above one another. For this purpose the ends of the rods 4 of adjacent cage walls 2, 3 are situated alternating above one another, as is shown in FIG. 1. Wood dowels 5 are provided for joining the rods of adjacent walls 2, 3, which dowels penetrate the rods 4 in aligned pass-through bores 6. In order to avoid the use of glue, a non-positive fixing of the wood dowels 5 in the pass-through bores 6 is sufficient. The cage 1 is not under tension in the direction of the wood dowels 5.

[0015] A floor 9 made of cardboard is inserted between the two lowermost rod layers 7, 8, which floor is also penetrated by the wood dowels 6. The charcoal to be lit can thus be pour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com