Physical deacidification deodorization method for vegetable oil

A physical deacidification, deacidification and deodorization technology, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of unfavorable fatty acid gas uplift and volatilization, fatty acid gas volatilization resistance, uneven distribution, etc., to achieve oil quality Guaranteed, short residence time, uniform oil film distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment one (sunflower seed oil) (use combined column of the present invention)

[0020] 1. Heat the sunflower oil (acid value 2.54mgKOH / kg, yellow 35 red, 2.2 Lovibond colorimeter 25.4mm tank) to 90°C and enter the decolorization tower, fully mix with decolorization clay and activated carbon and simultaneously Heat to 110°C, mix for 25 minutes and filter out activated clay and activated carbon to obtain deeply degummed and decolorized oil (color is tank yellow 20 red 1.5 Lovibond colorimeter 133.4mm tank).

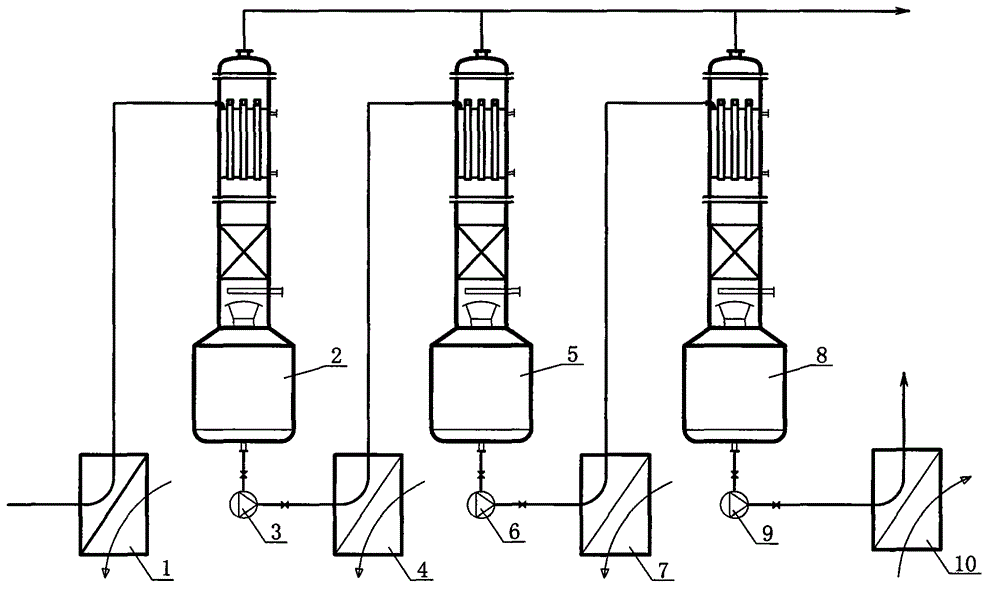

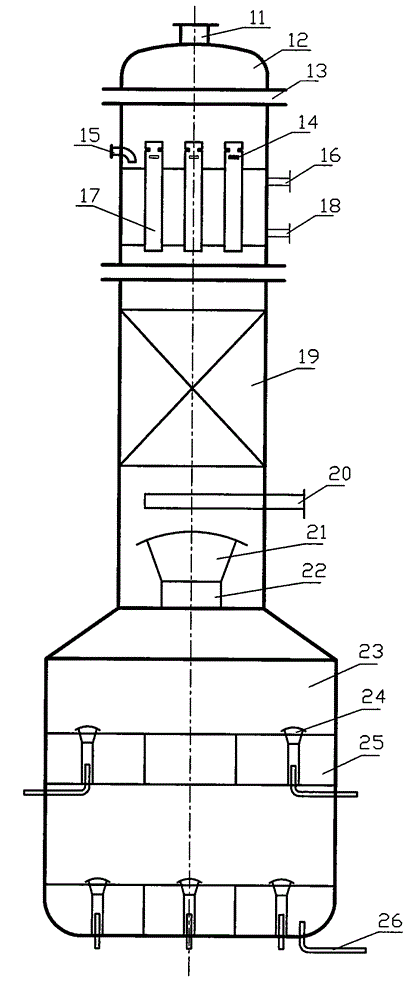

[0021] 2. Put the decolorized oil into the degasser to precipitate the oxygen contained in the oil, and heat it to 240°C and enter the No. 1 tube packing tray combination tower for about 45 minutes to extract it, and then heat it to 255 °C and enter the No. 2 tube packing After about 25 minutes, the tray-type combined tower is drawn out, heated to 260°C and entered into the No. 3 tube-packed tray-type combined tower, drawn out after about 15 minutes, and deodori...

Embodiment 2

[0022] Embodiment two (safflower seed oil) (use combined tower of the present invention)

[0023] 1. Heat the sunflower oil (acid value 1.96mgKOH / kg, yellow 35 red, 2.8 Lovibond colorimeter 25.4mm tank) to 90°C and enter the decolorization tower, fully mix with decolorization clay and activated carbon and simultaneously Heat to 110°C, mix for 25 minutes and filter out activated clay and activated carbon to obtain deeply degummed and decolorized oil (color is tank yellow 20 red 1.7 Lovibond colorimeter 133.4mm tank).

[0024] 2. Put the decolorized oil into the degasser to precipitate the oxygen contained in the oil, and heat it to 240°C and enter the No. 1 tube packing tray combination tower for about 45 minutes to extract it, and then heat it to 255 °C and enter the No. 2 tube packing After about 25 minutes, it is drawn out from the disc-type combined tower, heated to 260°C and entered into No. 3 tube-packed disc-type combined tower, and drawn out after about 15 minutes, and ...

Embodiment 3

[0025] Embodiment three (rapeseed oil) (use combined tower of the present invention)

[0026] 1. Heat the primary degummed raw rapeseed oil (acid value 2.72mgKOH / kg, color yellow 35 red 4.1 Lovibond colorimeter 25.4mm tank) to 90°C and enter the decolorization tower, fully mix with decolorization clay and activated carbon and simultaneously Heating to 110°C, mixing for 25 minutes to filter out activated clay and activated carbon to obtain deeply degummed and decolorized oil (color is tank yellow 25 red 2.1 Lovibond colorimeter 133.4mm tank).

[0027] 2. Put the decolorized oil into the degasser to precipitate the oxygen contained in the oil, and heat it to 240°C and enter the No. 1 tube packing tray combination tower for about 45 minutes to extract it, and then heat it to 255 °C and enter the No. 2 tube packing After about 25 minutes, it is drawn out from the combined tray tower, heated to 260°C and entered into the No. 3 tube packed tray-type combined tower, drawn out after a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap