Impeller fixing structure and fixing method of a miniature rotary mechanical pump

A technology of rotating machinery and fixed structure, applied in mechanical equipment, components of pumping devices for elastic fluids, pumps, etc., can solve the problems of increased assembly difficulty, increased machining accuracy, large assembly stress, etc., and achieves axial positioning. The effect of easy adjustment, small change of parts and high fixing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

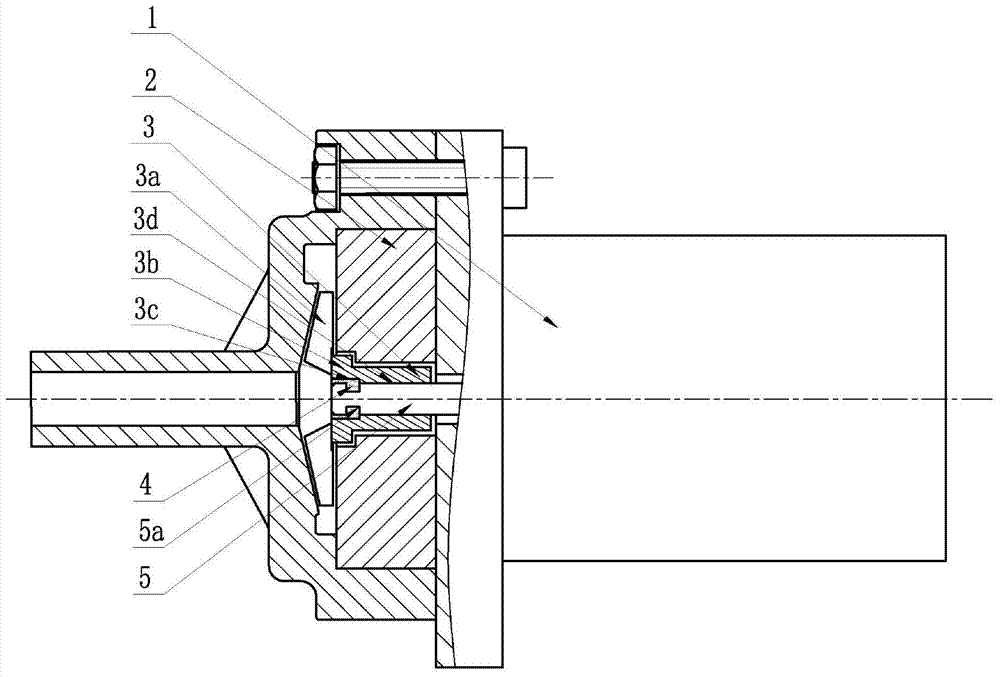

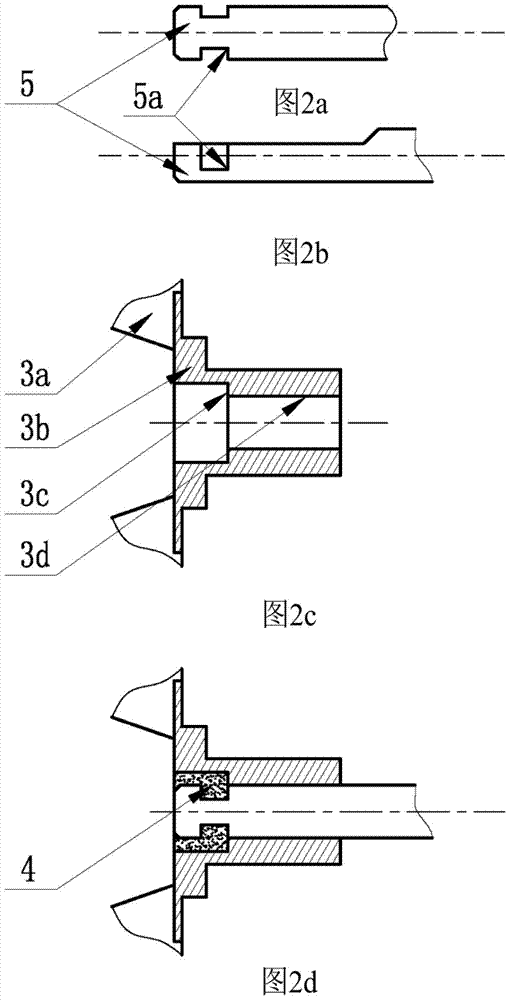

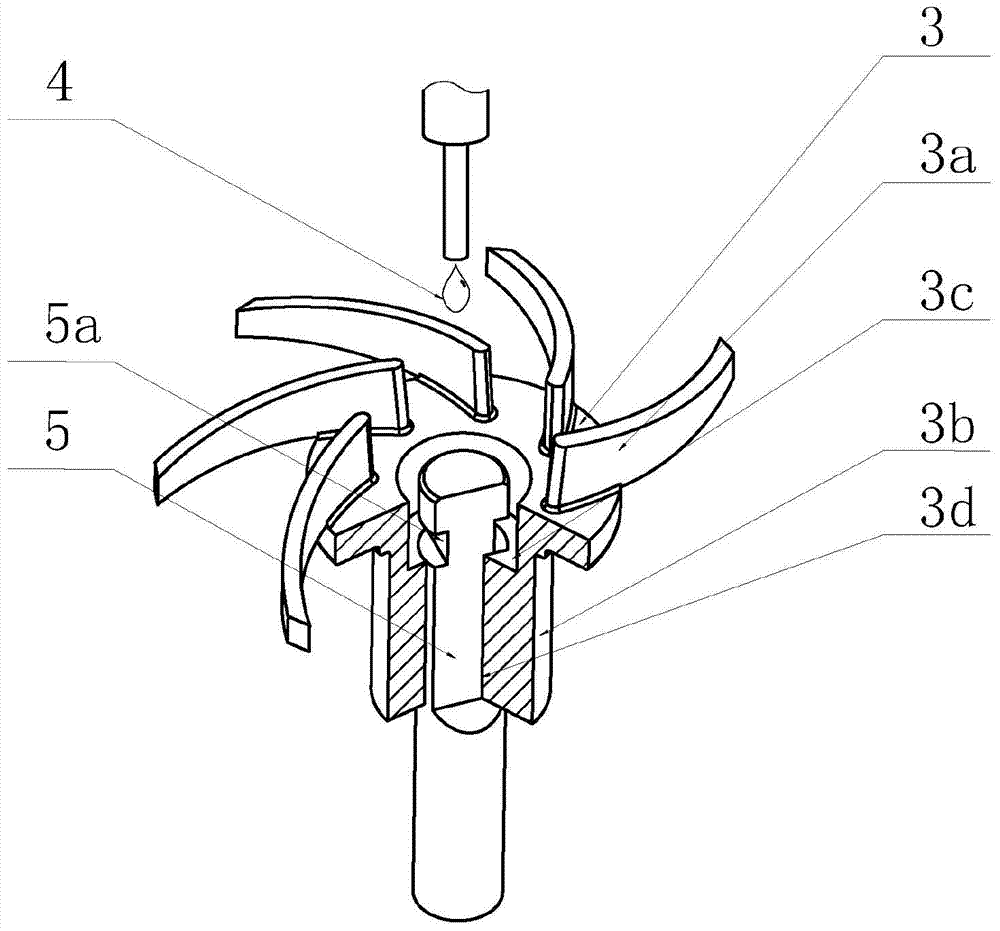

[0023] Such as figure 1 As shown, the impeller 3 is fixed on the motor shaft 5, and the blades 3a on the impeller 3 are placed in the pressurized water chamber. One end surface of the front cover 2 is in close contact with the motor 1 and both are concentric. The output shaft section of the motor shaft 5 is provided with two square straight grooves 5a, and the opening direction of the square straight grooves 5a is perpendicular to the axial direction of the motor. One end of the impeller hub 3b is provided with a packing stepped hole 3c, and the diameter of the stepped hole is slightly larger than that of the shaft hole.

[0024] figure 2 The fixing structure of the present invention is described in more detail. Such as figure 2 The output shaft section of the motor shaft 5 shown in b is processed with a D-shaped flat part to cooperate with the D-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com