Pressurizer for centrifugal fan

A centrifugal fan and supercharger technology, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve problems such as delayed combustion of fuel, loss of function, and obstruction of exhaust gas removal.

Inactive Publication Date: 2015-07-29

于林 +1

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] All of them have been in a state of overload for a long time. For example, the load of a single-cylinder small four-wheel transport tractor is 4-8 tons, which is equivalent to the load of a Jiefang car in the 1960s and 1970s. A four-axle truck can The load is 40-50 tons... So the place they pass is a string of black smoke, which is the result of a reasonable ratio of combustion. How to give full play to the fuel efficiency of a diesel engine has been explored and practiced for many years. A late-stage remedial measure, how to increase the intake air volume of a diesel engine that has been finalized is also one aspect of the remedial measures. Exhaust gas turbocharging is commonly used now. Although this method increases the intake air volume, it also hinders the combustion after combustion. The smooth removal of exhaust gas has become a great regret for the exhaust gas turbocharger! The working principle of the exhaust gas turbocharger: directly see that the displacement and intake air volume of a diesel engine are equal, and the exhaust gas removed by it drives the worm gear, and the exhaust gas worm gear drives the intake worm wheel blades to generate power to drive air into the cylinder. Perpetual motion machine, but it still has a certain effect in the actual production and application process. The effect comes from the sharp reduction of the space above the cylinder in the exhaust stroke of the piston, so that the exhaust gas is compressed, and the compressed exhaust gas is the power of the turbocharger. During this period of force transformation, the engine becomes an air compressor and consumes energy. The consumption of this physiological function is like when we climb a mountain wearing a mask and climbing a mountain without a mask will produce completely different physiological effects. It is very easy for a healthy person to walk with a travel bag on his back, but a person with a lung disease has to walk a few steps and stop when he walks empty-handed... The same is true for machinery, so the current working method of the exhaust gas turbocharger is not advisable!

[0004] Working conditions of the exhaust gas turbocharger: the exhaust gas turbocharger generally works at a temperature above 600°C. If the oil supply system fails and causes fuel oil to burn sluggishly, the exhaust temperature will rise sharply, burning the impeller blades, causing the blades to fall off and completely Loss of function, in this case the supercharger is useless, this working condition is not available

[0005] In addition, the currently reported belt turbocharger and air wave supercharger have no similarities with the centrifugal fan supercharger from the current market share, so no comment will be made here.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0016] The present invention is not only a method pattern, but also a tangible utility device. It has changed the situation that many small and medium-sized agricultural diesel engines cannot be equipped with superchargers. Realize that every machine has a supercharger, and can be widely promoted and used.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

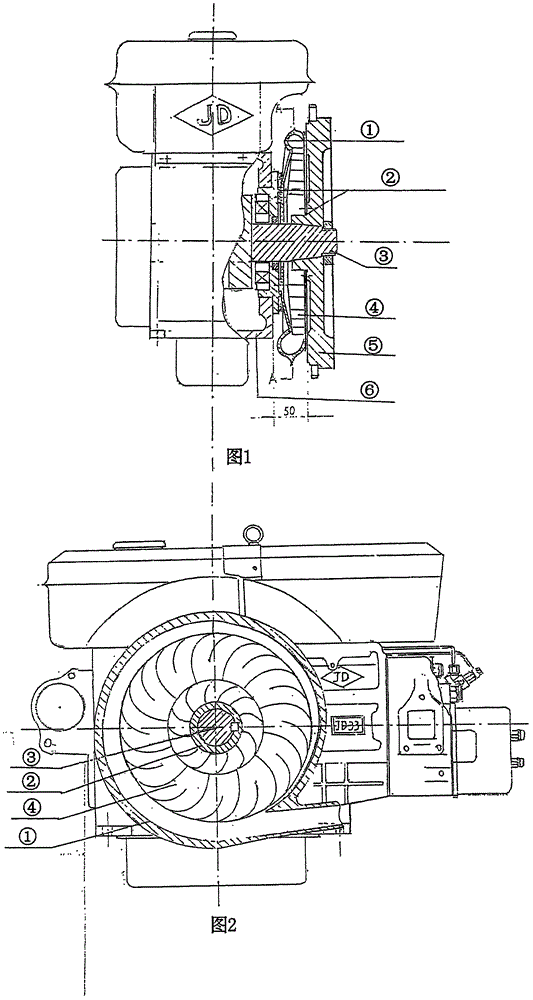

The invention provides a pressurizer for a centrifugal fan, and aims at solving the problems that the air feeding quantity can be increased by the existing exhaust turbine pressurizer, but the exhaust cannot be discharged smoothly after combustion; exhaust turbine blades at the high temperature more than 600 DEG C for a long time are deformed, fall down and damaged. The pressurizer for the centrifugal fan is high in lubricating performance of a crankshaft, and extremely small in axial and radial gaps; the outputted power directly drives an impeller of the pressurizer to forcibly increase the air feeding power of an engine by flow concentrating of a turbine housing to achieve pressurizing. The pressurizer for the centrifugal fan is that the impeller of the fan and a flywheel of the engine are integrated; the engine pressurizer is changed from the original auxiliary device into the normal device of the engine; a pressurizing device is provided for each engine to achieve reasonable combustion; the efficiency can be increased; the energy can be saved; the carbon discharge can be reduced; the attached figure in the abstract is shown in figure 1; (1) is the turbine housing, (2) is the original magnetic motor positioning step, (3) is the crankshaft, (4) is the impeller, (5) is the flywheel, and (6) is the cylinder body in the figure.

Description

[0001] Technical fields: engineering series, thermal engine range. Background technique [0002] The current distribution and operation status of diesel engines: now basically all small and medium-sized diesel engines are used in irrigation and drainage of farmland, processing and harvesting of agricultural products, agricultural vehicles, agricultural tractors, transport tractors, various passenger and cargo transport vehicles, construction machinery, drilling and drilling Well machinery, small and medium-sized generator sets are widely used in all walks of life. [0003] All of them have been in a state of overload for a long time. For example, the load of a single-cylinder small four-wheel transport tractor is 4-8 tons, which is equivalent to the load of a Jiefang car in the 1960s and 1970s. A four-axle truck can The load is 40-50 tons... So the place they pass is a string of black smoke, which is the result of a reasonable ratio of combustion. How to give full play to the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F04D29/28F04D25/02

CPCF04D29/281F02B39/04F04D25/02

Inventor 罗明哲

Owner 于林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com