Frictionless quick-response balance system

A fast-response, balanced system technology, applied in the direction of fluid pressure actuators, servo motors, mechanical equipment, etc., can solve problems such as insufficient air supply pressure, insufficient air film thickness, and the possibility of damage to lifting devices and machine tools, etc., to achieve guaranteed Safety and reliability, improvement of work performance, effect of reducing reaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

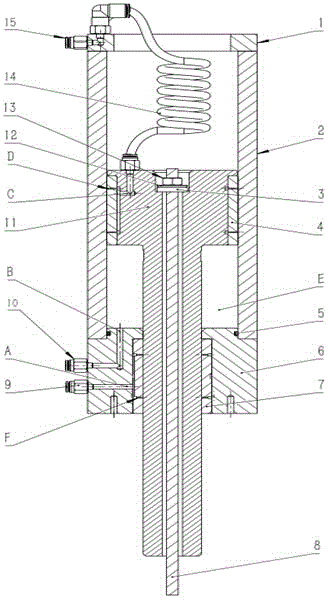

[0012] The structure diagram of the present invention is as figure 1 As shown, the frictionless quick-response balance system of the present invention includes an upper end cover 1, a cylinder body 2, a piston bushing 4, a lower end cover 6, a lower end cover bushing 7, a steel wire rope 8, and a piston rod 11, wherein the piston rod 11 is inserted into In the hollow cavity provided by the cylinder body 2, the piston bushing 4 is sleeved on the outer side of the upper end of the piston rod 11, and the outer side of the piston bushing 4 is in contact with the inner side wall of the cylinder body 2, and the upper and lower ends of the cylinder body 2 are respectively equipped with The upper end cover 1 and the lower end cover 6, the lower end cover shaft sleeve 7 is set on the inner side wall of the lower end cover 6, one end of the piston rod 11 is placed in the hollow cavity provided by the cylinder body 2, and the other end of the piston rod 11 passes through the shaft of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com