Automobile shock absorber structure

A technology for shock absorbers and automobiles, applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems of high cost, complex structure, and difficult processing of the inner wall of the cylinder body, etc. High stability, the effect of improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

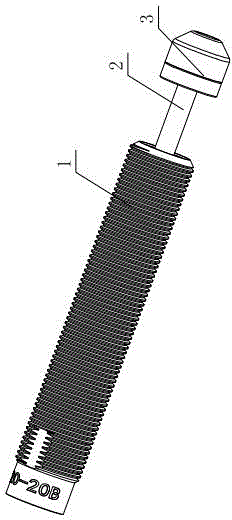

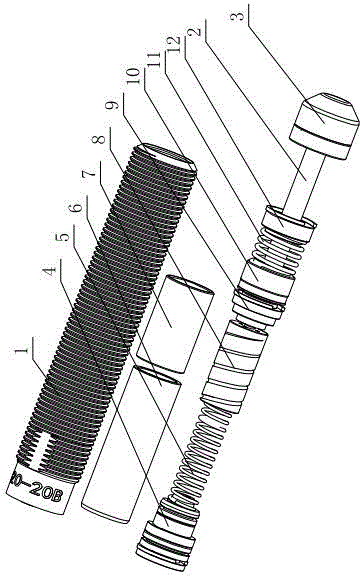

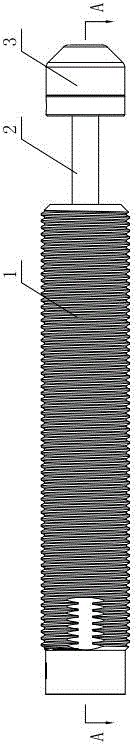

[0016] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the automobile shock absorber structure of this embodiment includes a cylinder body 1, the inner wall of the cylinder body 1 is a smooth and flat structure, a piston 8 is installed in the cylinder body 1, and a push rod 13 is inserted inside the piston 8, which is located in the cylinder body. The afterbody of body 1 is equipped with the 3rd cylinder cap 4, and the first spring 5 is installed between the 3rd cylinder cap 4 and the ejector rod 13, and the 3rd cylinder cap 4 becomes step-shaped structure, and the step surface place of the 3rd cylinder cap 4 and A vibrating tube 6 is installed between the outer peripheral surfaces of the piston 8, and the vibrating tube 6 has a hollow cylindrical structure, and the outer peripheral surface of the vibrating tube 6 is att...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com