Centrifugal type three-gear automatic speed changing system for electric car

An automatic speed change, centrifugal technology, applied in the direction of transmission, gear transmission, belt/chain/gear, etc., can solve the problems of unfavorable promotion and later use, complex system, high cost, widen the range of transmission ratio and system stability. The effect of high performance and reduced performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

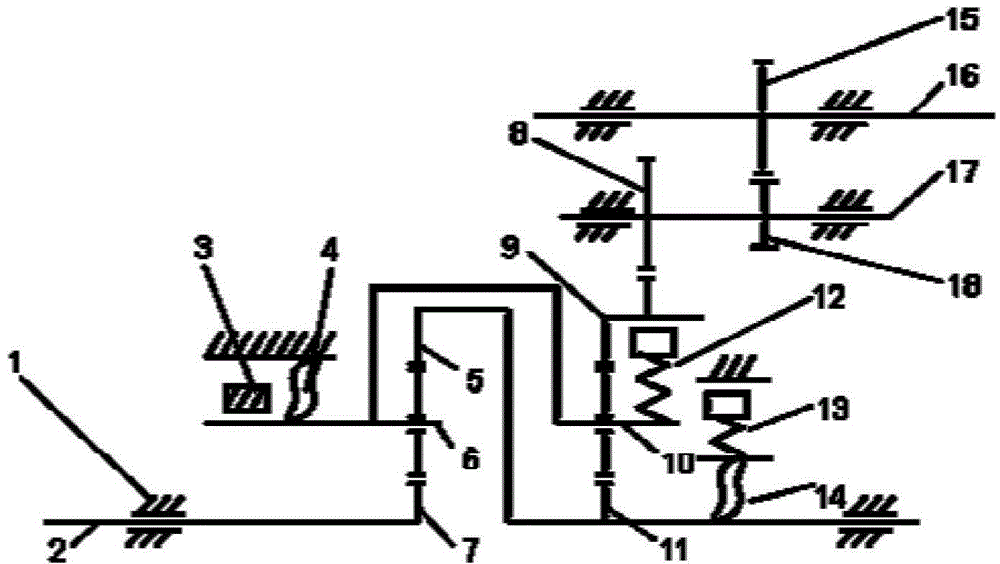

[0050] figure 1 An implementation form according to the present invention is shown, which includes: the final drive and the transmission, both of which are integrated and wrapped by the casing 1; the final drive can be connected before the transmission or after the transmission.

[0051] Wherein, the transmission includes:

[0052] Transmission mechanism, which is a double-row planetary system composed of input shaft 2, front row sun gear 7, front row planet carrier 6, front row ring gear 5, rear row planet carrier 10, rear row sun gear 11 and rear row ring gear 9 A gear mechanism, wherein the front row sun gear 7 is connected to the input shaft 2, the front row planet carrier 6 is connected to the rear row planet carrier 10, and the front row ring gear 5 is connected to the rear row sun gear 11; and

[0053] Regulates the shift mechanism, which includes:

[0054] F1 one-way overrunning clutch 4, which is arranged between the housing 1 and the front row planet carrier 6 to p...

Embodiment 2

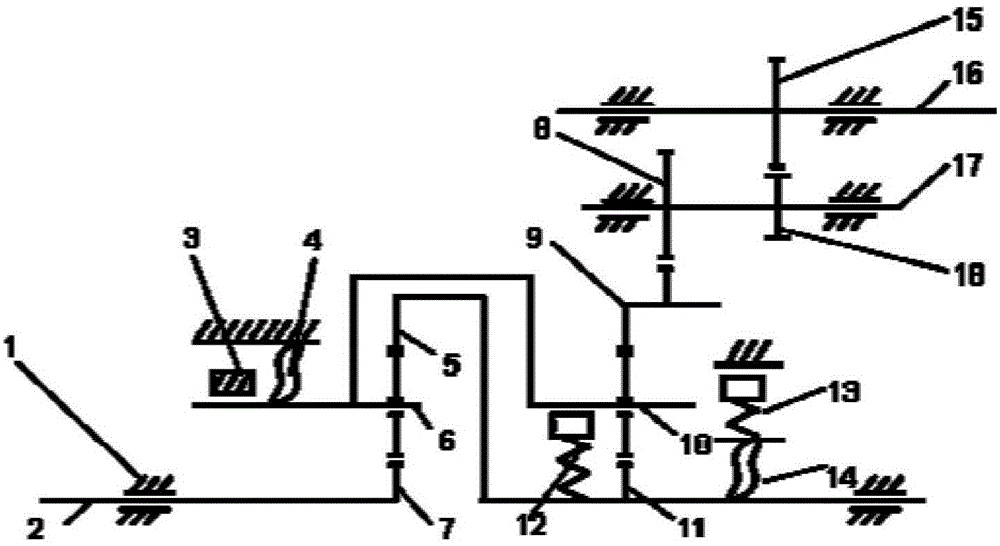

[0074] figure 2 Another implementation form of the present invention is shown, the electric vehicle centrifugal three-speed automatic transmission of this figure and the centrifugal clutch 12 in the final drive are located between the rear row planet carrier 10 and the rear row sun gear 11; its Effect is, when being in the forward third gear, the centrifugal clutch 12 works, and the rear planetary carrier 10 is connected with the rear sun gear 11, making the front and rear planetary gears as a whole.

[0075] Such as image 3 and Figure 4 Different embodiments of the final drive are shown, including:

[0076] a single-row double-stage planetary gear set or a single-row single-stage gear set, which is connected between the input shaft 2 and the front sun gear 7;

[0077] The intermediate shaft 17 is connected to the rear ring gear 9 and outputs power.

Embodiment approach

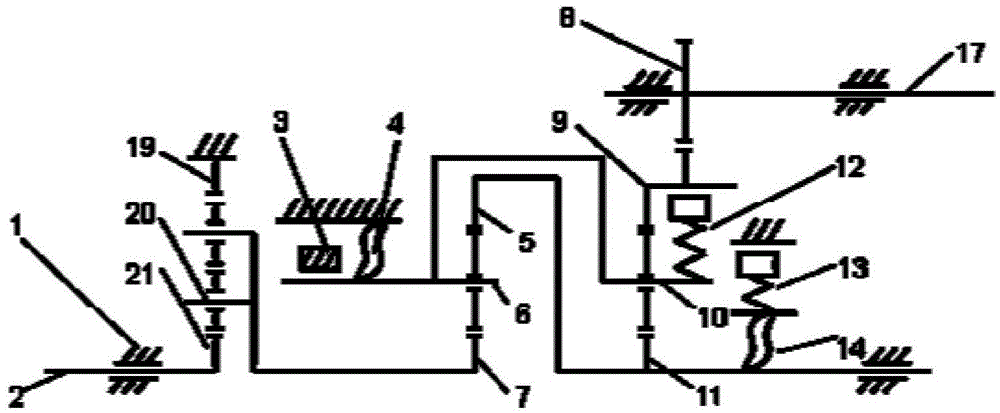

[0079] Such as image 3 An embodiment of the final drive is shown, and the single-row double-stage planetary gear set includes:

[0080] a sun gear 21, which is connected to the input shaft 2;

[0081] a double planetary gear, which is arranged on the planetary carrier 20 and meshes with the sun gear 21, so as to rotate around the sun gear 21 while itself rotating;

[0082] Planet carrier 20, which is connected to the front sun gear 7, and reversely decelerates the power input to the front sun gear 7;

[0083] The ring gear 19 is fixed on the housing 1 and meshes with the double planetary gears.

[0084] The electric vehicle centrifugal three-speed automatic transmission of this example and the final drive in the final drive are located before the input shaft, including a single-row two-stage planetary gear set, ring gear 19, planet carrier 20, sun gear 21, wherein the ring gear 19 is connected with the housing, the input shaft is connected with the sun gear 21, and the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com