High-precision cable force testing instrument of magnetic permeability cable and test method thereof

A tester, high-precision technology, applied in force/torque/work measuring instruments, instruments, measuring devices, etc., can solve the problems of complex calculation steps, 3rd harmonic interference, data processing difficulty, etc., to achieve a wide range of applications, Good durability and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

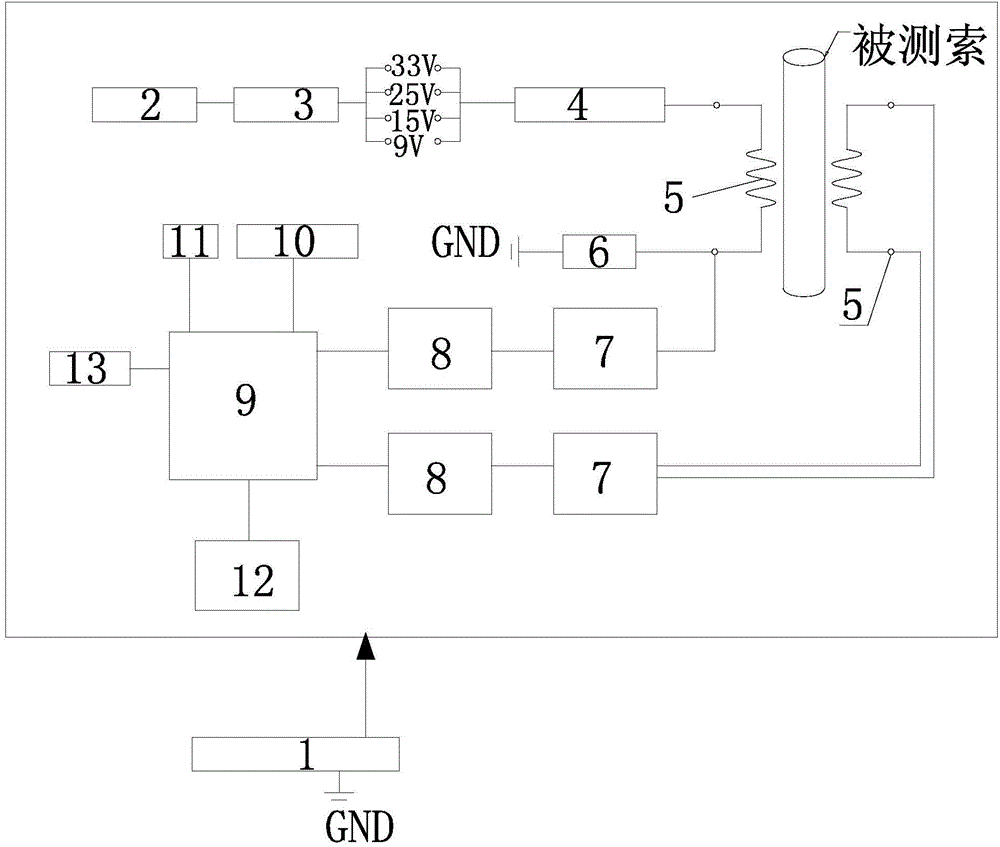

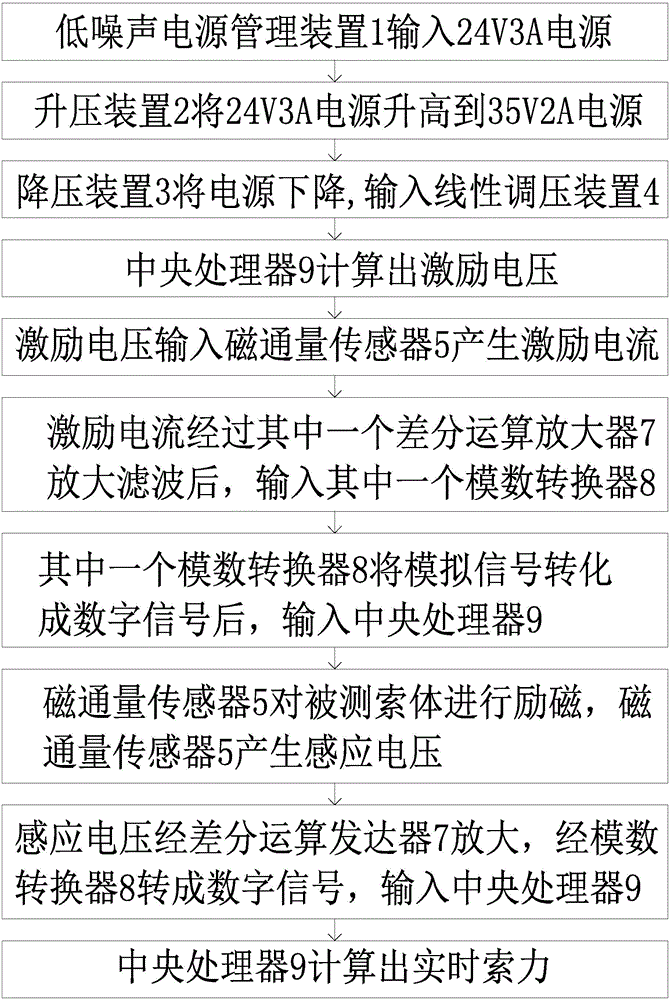

[0034] Please see attached figure 1 As shown, a high-precision cable force tester for magnetic cables includes a low-noise power management device 1, a voltage booster 2, a voltage drop device 3, a linear voltage regulator 4, a magnetic flux sensor 5, a MOS tube 6, two Differential operational amplifier 7, two analog-to-digital converters 8, central processing unit 9, 485 isolation circuit 10, network card 11 and SD card memory 12; one end of the described step-up device 2 and one end of the described step-down device 3 connected, the other end of the pressure reducing device 3 is connected to one end of the linear voltage regulating device 4; the magnetic flux sensor 5 is in a ring structure, and the magnetic flux sensor 5 is sleeved on the cable body to be tested, The two ends of one side of the magnetic flux sensor 5 are respectively connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com