Grinding device

A technology of grinding discs and disc grinding machines, which is applied in the preparation of test samples, etc., can solve problems such as hot hands cannot be handled, grinding discs are broken, silicon wafers are heated, etc., and it is suitable for popularization and application, realizing automation and preventing fragmentation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

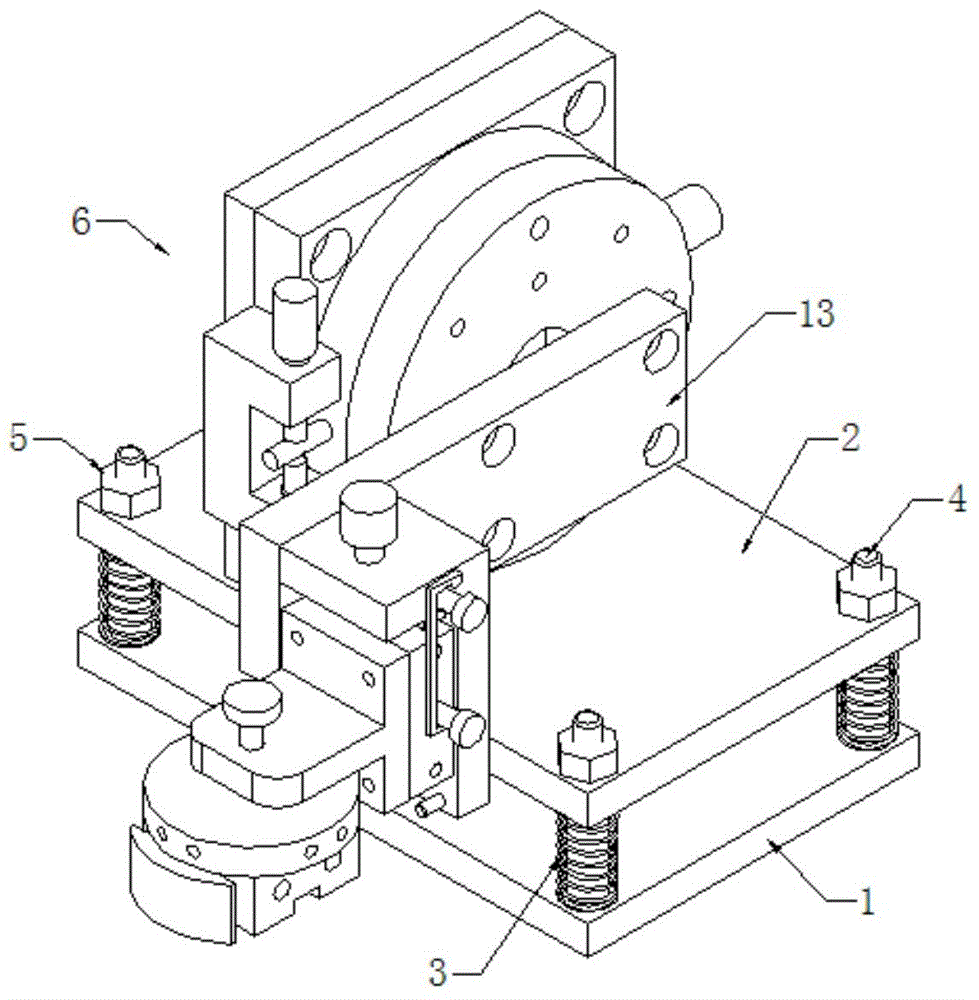

[0037] see Figure 1~5 As shown, a grinding device includes a frame and a grinding machine located on the frame, and also includes a clamping mechanism 6,

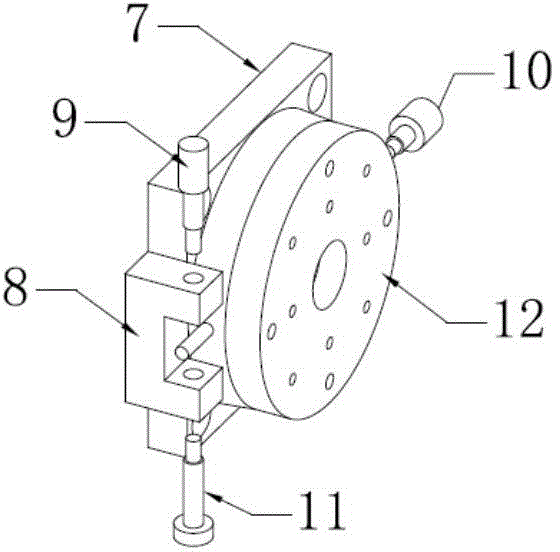

[0038] The clamping mechanism includes a liftable platform, and the surface of the liftable platform is fixed with a rotating pillow block, and the rotating surface of the rotating sliding table of the rotating pillow block is located in a vertical plane, so that the rotating sliding table has a rotation relative to the lifting platform. degrees of freedom;

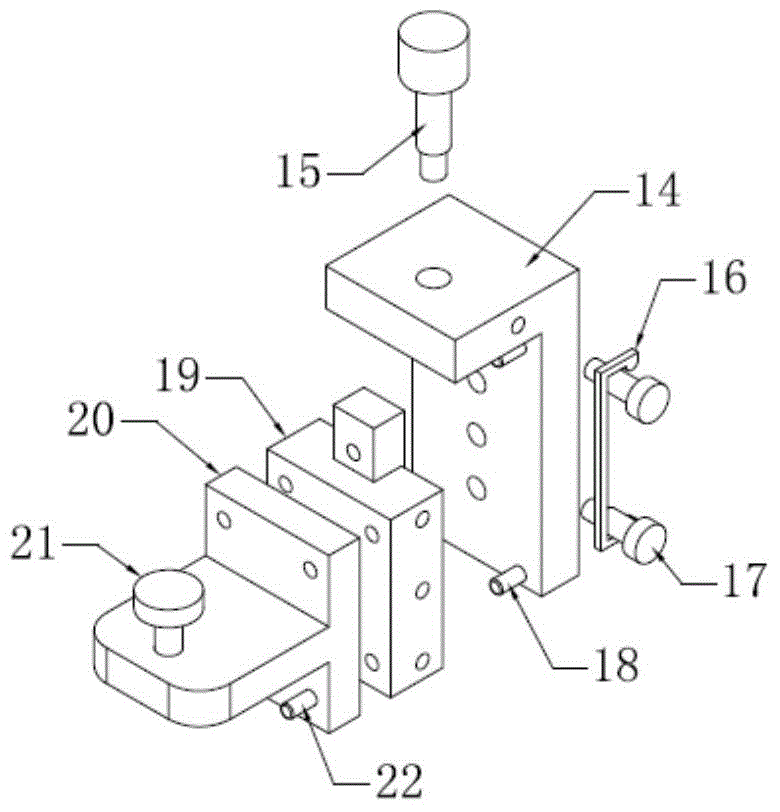

[0039] A connection plate 13 is fixed on the rotary slide of the rotary pillow block, one end of the connection plate is fixedly connected to the rotary slide, and the other end is fixed with an up and down fine-tuning mechanism;

[0040] The up and down fine-tuning mechanism includes a fixed plate 14, a precision linear guide rail 19 and a locking block 20, one side of the fixed plate is fixedly connected with the connecting plate, and a precision linear guide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com