Silicone compounds, modified imide resins, thermosetting resin compositions, prepregs, resin-coated films, laminates, multilayer printed wiring boards, and semiconductor packages

A technology of siloxane compound and compound, which is applied in the direction of semiconductor devices, synthetic resin layered products, semiconductor/solid device components, etc., can solve the problems of low solubility, processability, difficult to handle, etc., and achieve low curing shrinkage properties, low thermal expansion, and good dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0225] Hereinafter, the present invention will be described in more detail using the following examples, but the present invention is not limited to these examples.

[0226] Furthermore, the curing shrinkage was measured and evaluated by the following method using the resin sheets obtained in the respective Examples and Comparative Examples, and the glass transition temperature, thermal expansion coefficient, copper foil adhesion, and copper-containing solder resistance were measured and evaluated using the copper-clad laminate. Thermal properties, flexural elastic modulus, and dielectric properties were measured and evaluated by the following methods.

[0227] (1) Measurement of cure shrinkage of resin sheet

[0228] A 5 mm square resin plate (thickness 1 mm) was produced, and thermomechanical analysis was performed by a compression method using a TMA test apparatus (manufactured by TA Instruments, Q400). After the resin plate was mounted on the device in the Z direction, th...

manufacture Embodiment 1

[0243] Production Example 1: Production of Siloxane Compound (i-1)

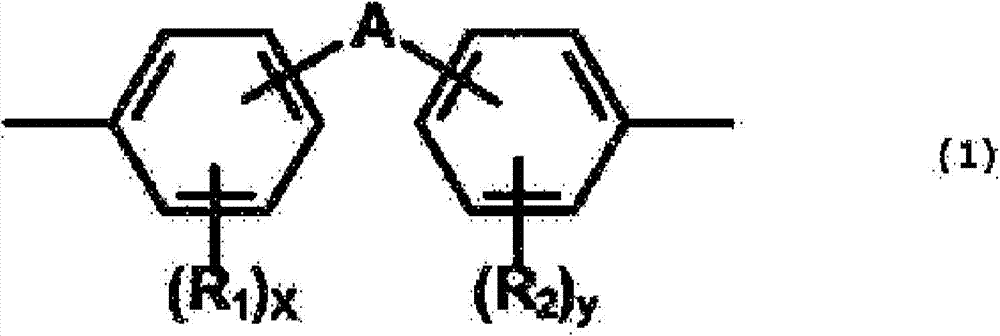

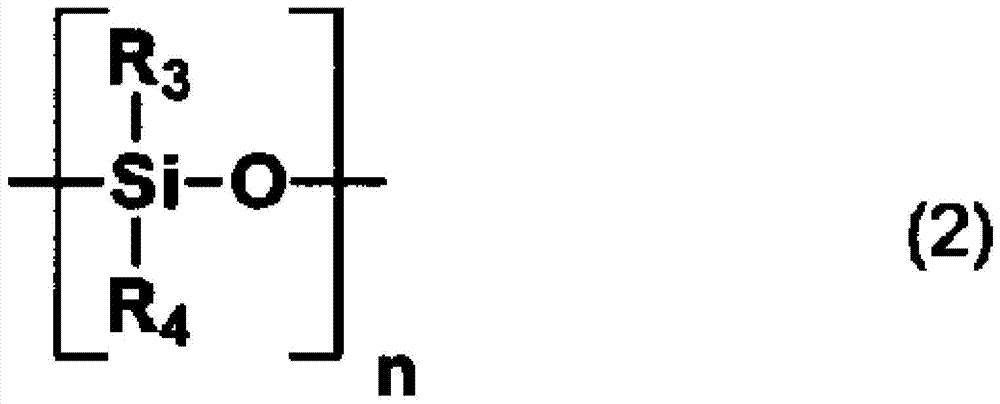

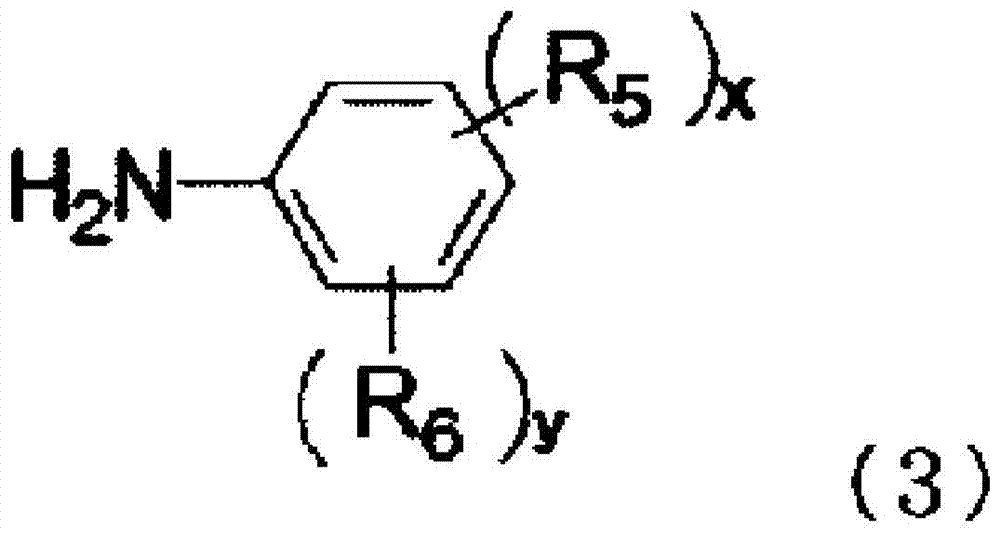

[0244] To a 2-liter reaction vessel with a thermometer, a stirring device, and a moisture meter with a reflux condenser capable of heating and cooling, add 3,3'-dimethyl-4,4'-diaminobiphenyl: 0.27 g, terephthalaldehyde: 0.33 g, X-22-161B: 199.4 g, propylene glycol monomethyl ether: 300.0 g, and reacted at 115°C for 4 hours, then heated to 130°C and dehydrated by atmospheric concentration to obtain a mixture containing Solution (Mw: 30000, resin component: 90 mass %) of modified siloxane compound (i-1) with aromatic azomethine.

manufacture Embodiment 2

[0245] Production Example 2: Production of Siloxane Compound (i-2)

[0246] To a 2-liter reaction vessel equipped with a thermometer, a stirring device, and a moisture meter with a reflux condenser and capable of heating and cooling, 4,4'-diaminobenzamide: 0.27 g, terephthalaldehyde were added. : 0.31g, X-22-161B: 199.4g, propylene glycol monomethyl ether: 300.0g, after reacting at 115°C for 4 hours, the temperature was raised to 130°C and dehydration was carried out by concentration at atmospheric pressure to obtain an aromatic azomethine containing of the modified siloxane compound (i-2) (Mw: 31000, resin component: 90% by mass).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap