Cleaning method for longitudinal cracks on the surface of continuous casting slab based on thermite self-propagating technology

A cleaning method and self-propagating technology, applied in aluminothermic welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of declining casting yield, harsh operating environment, hidden safety hazards, etc., and improve billet yield. , the effect of reducing production costs and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0051]

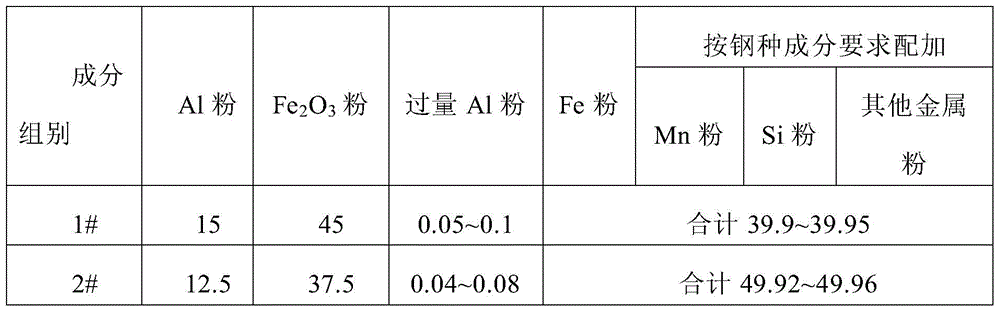

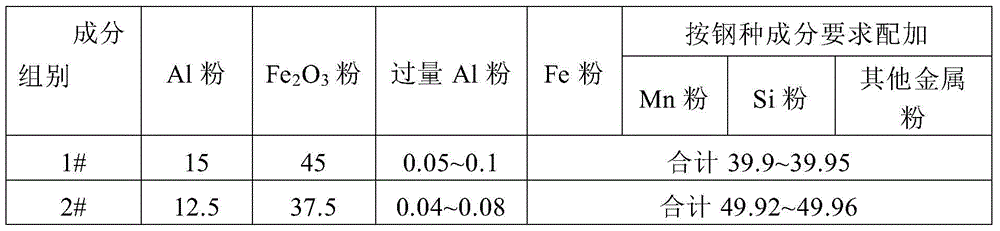

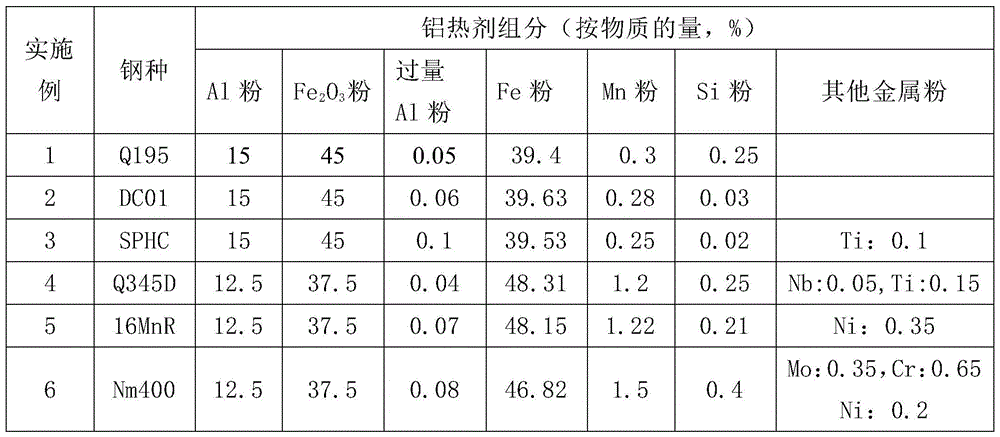

[0052] In the examples in Table 3, 1, 2, and 3 are ordinary steel or very microalloy steel, and the liquidus temperature is relatively high, so a larger ratio of thermite is used; 4, 5, and 6 are microalloy steel or medium-high Alloy steel has a relatively low liquidus temperature, so a relatively small amount of thermite is used, but the ratio of the two kinds of thermite can ensure sufficient heat of reaction. Similarly, the liquidus of the three steel grades 4, 5, and 6 is relatively low, and the excess Al used to protect the elemental substances in them from being oxidized is less.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com