Thermoplastic polyester elastomer composition and method for preparing auxiliary spring

A polyester elastomer and thermoplastic polyester technology, applied in the field of materials, can solve problems such as failure to meet the requirements of the suspension shock absorption system, damage and permanent deformation, and increase processing costs, so as to improve stability and processing efficiency, high dynamic load, The effect of reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Mix 100 parts by weight of polyethylene terephthalate with a number average molecular weight of 30,000 and 33.3 parts of polycaprolactone diol with a number average molecular weight of 10,000, stir for 1 hour at a temperature of 230 to 245° C. and a pressure of 130 Pa, and wait for After the resin became transparent, it was taken out and cooled to obtain a polyester-polyester block copolymer (that is, a thermoplastic polyester elastomer).

[0022] At a temperature of 225-235° C., the above polyester-polyester block copolymer, heat stabilizer, antioxidant and nucleating agent are melt-blended on a twin-screw extruder, and quenched in water for granulation. The nucleating agent is talcum powder, and the addition amount is 2wt% of the polyester elastomer composition. The added amount of the heat stabilizer and the antioxidant is respectively 1wt% of the polyester elastomer composition.

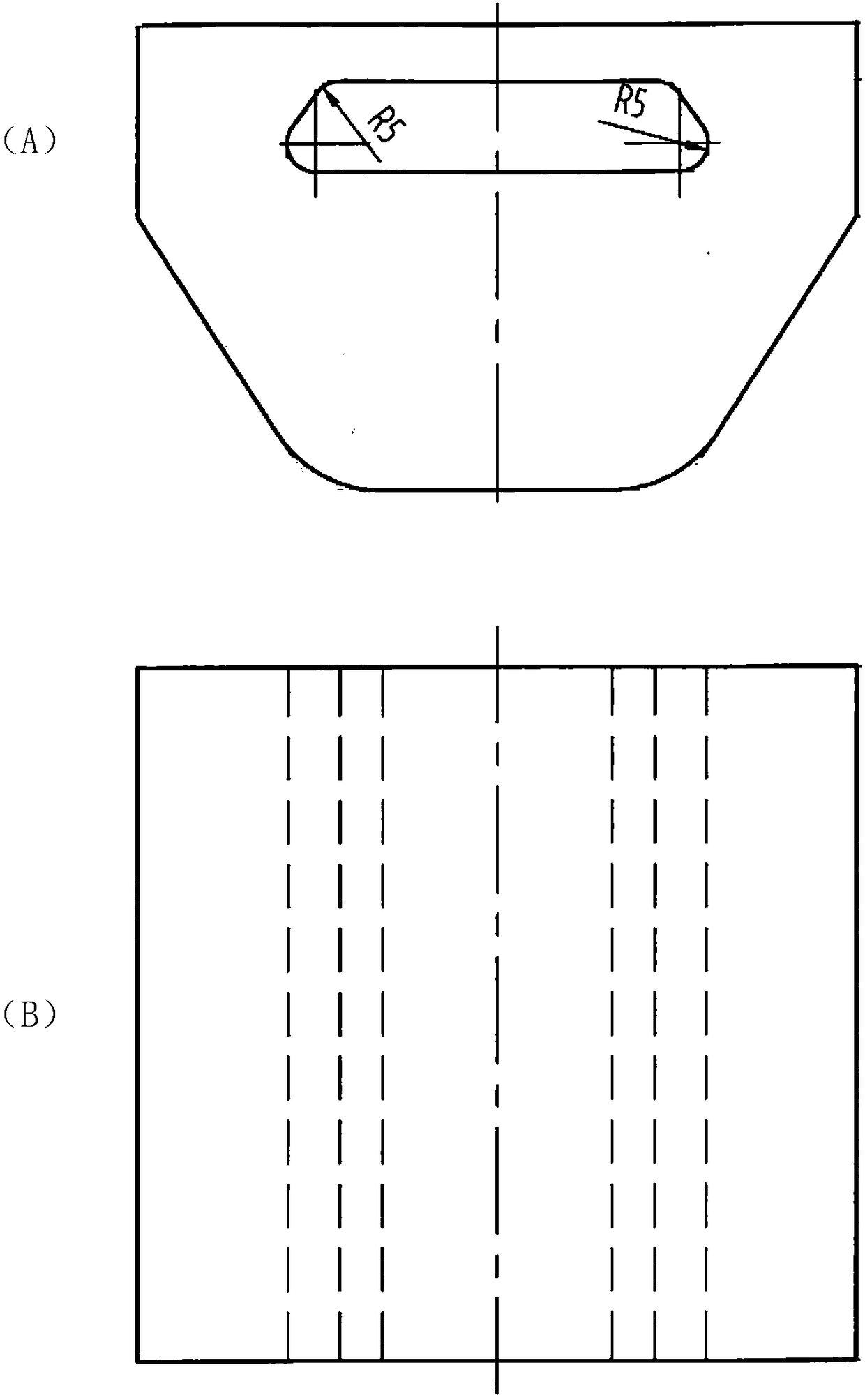

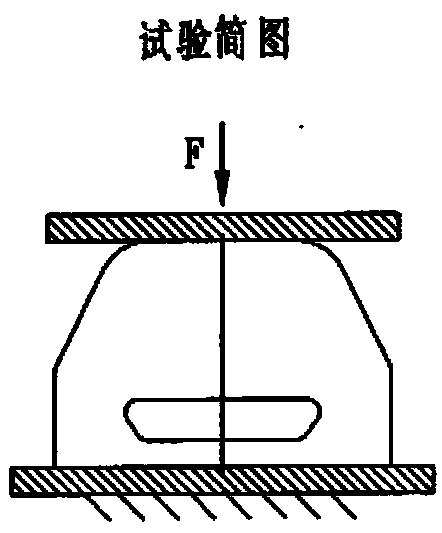

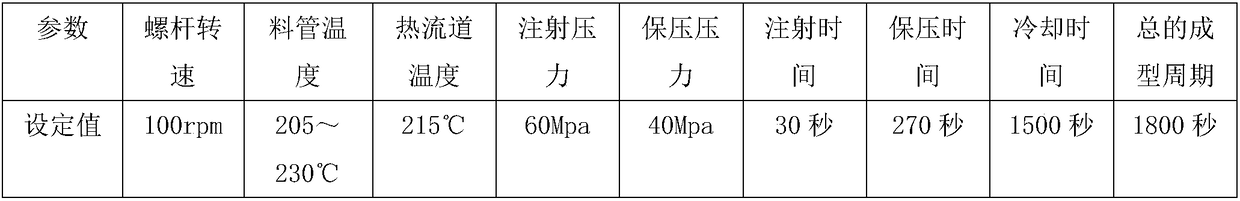

[0023] Through a six-station injection molding machine and a hot runner injection mol...

Embodiment 2

[0028] The difference from Example 1 is that the polycaprolactone diol with a number average molecular weight of 5,000 is used instead of the polycaprolactone diol with a number average molecular weight of 10,000, and the others are the same as in Example 1.

Embodiment 3

[0030] The difference from Example 1 is that the polycaprolactone diol with a number average molecular weight of 20,000 is used instead of the polycaprolactone diol with a number average molecular weight of 10,000, and the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com