Electric car chassis with lithium battery

A technology for electric vehicles and lithium batteries, applied in electric power units, power units, vehicle components, etc., can solve problems such as heavy workload, achieve compact layout, convenient pipeline installation and connection, and reduce maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

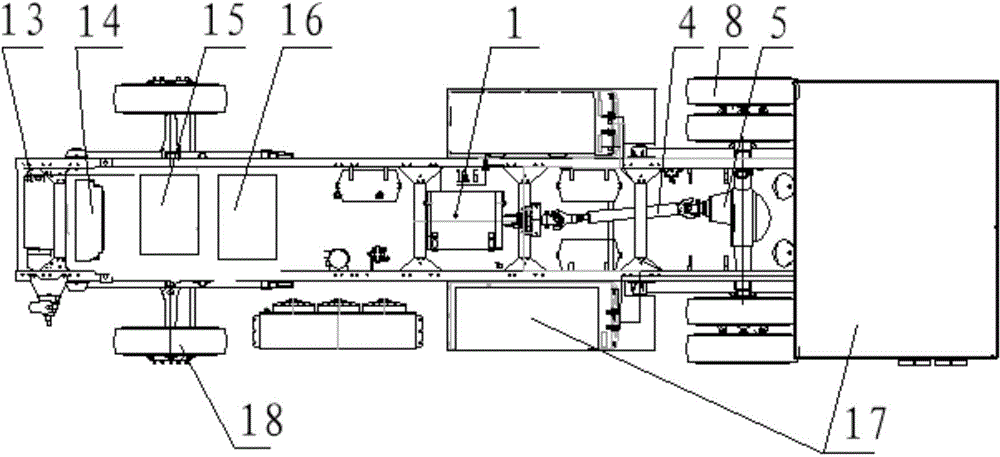

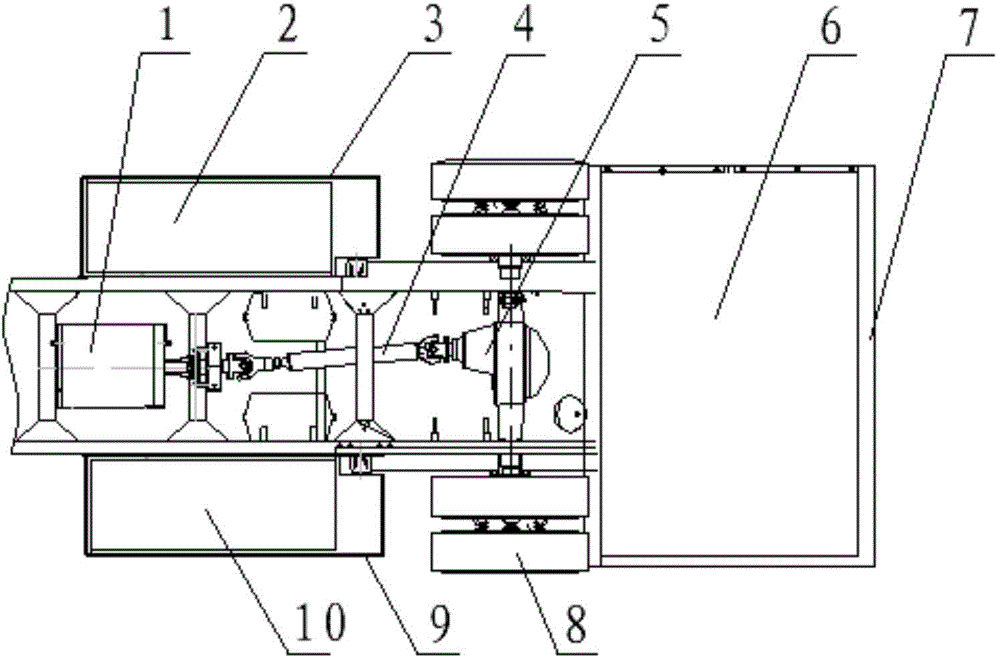

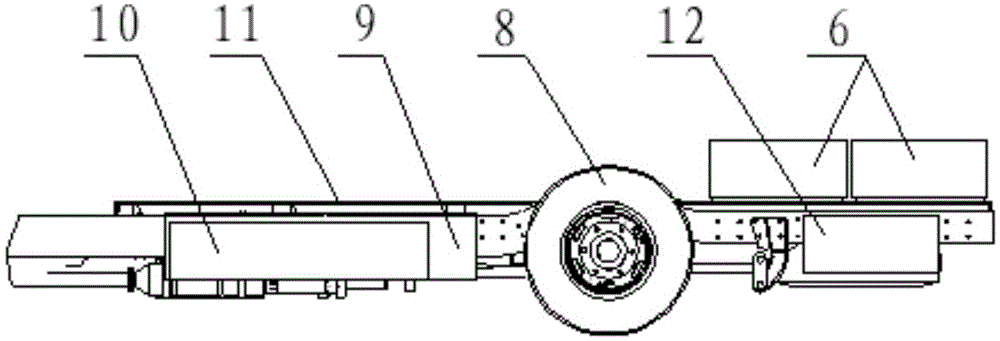

[0014] Such as figure 1 , figure 2 , image 3 As shown, the lithium battery electric vehicle includes front wheels 18, rear wheels 8, vehicle body floor 11, luggage compartment 7 positioned at the rear of the car, drive motor 1, transmission shaft 4, rear drive axle 5, power steering pump 13, cooling water tank 14, High-voltage control cabinet 15, electric air compressor 16, power battery pack 17, power steering pump 13 are arranged on the vehicle body, utilize the space in front of the vehicle body, and are close to the steering booster, so that the steering system is more compact, the pipeline is short, and the connection is convenient. Radiating water tank 14 is positioned at the back of power steering pump 13, and the front of other parts, and vehicle is in running process, is beneficial to heat dissipation, improves heat dissipation effect. The high-voltage control cabinet 15 is arranged behind the cooling water tank, which is conducive to maintenance. The electric ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com