Anti-swinging control method capable of adjusting auxiliary suspension load transportation

A technology of load and movement, applied in the field of cranes such as assisted driving, which can solve the problems of bad drivers, unfaithful set values, increased costs and failure risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

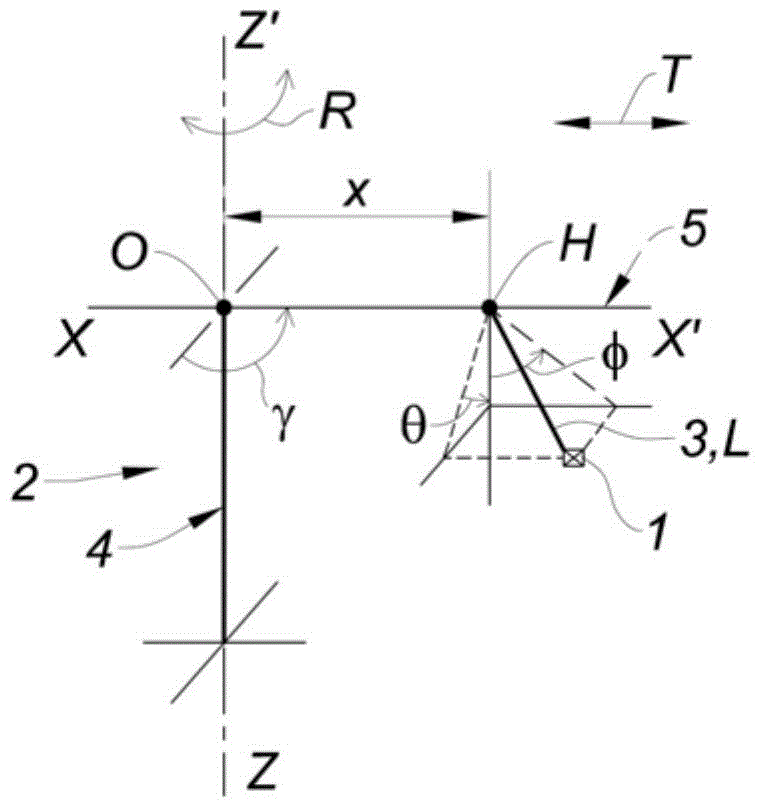

[0041] The invention relates to the control of hitch points suspended from a crane 2 H The method of displacement of the load 1, the attachment point H Designed to be able to rotate according to the rotational movement in oscillation about a first vertical axis (ZZ') called the "towards axis" R displacement, and / or along a so-called "distribution axis" such as figure 1 A second axis (XX') intersecting said orientation axis (ZZ') as shown according to translational motion T displacement.

[0042] mount point H Preferably formed by a trolley guided in translation along the distribution axis (XX'), said trolley being driven by any suitable motorized means.

[0043] The load 1 is suspended at the hitch point by the suspension device 3 H , the suspension device 3 is, for example, a suspension cable and is similarly referred to below as such a cable.

[0044] Preferably, the length of the suspension cable 3 can be made L change to enable changing the hitch point of the suspen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com